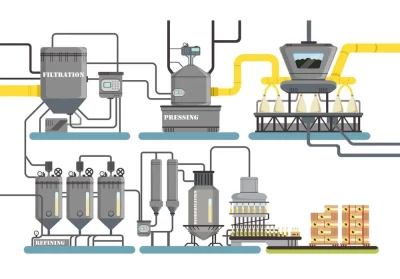

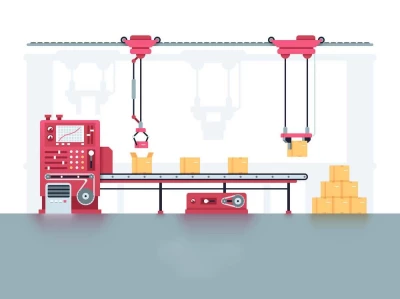

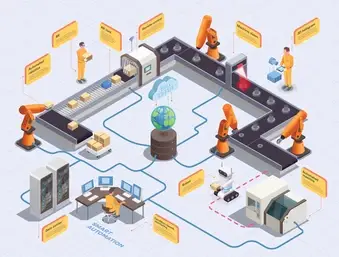

Your automated line starts with us

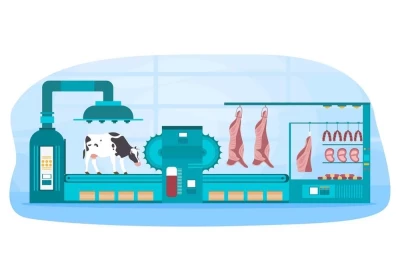

RGMTSI provides access to the world's highest quality automated manufacturing equipment and product development solutions in wide variety of market concepts such as Food Processing, Pharmaceutics, Nutraceutics, Meat processing and Dairy plant industries among others.