- Home

- Commercial Dairy

- Filling Equipment

Filling Equipment

Filling describes the process whereby a receptacle - most commonly a cup, cone or tub – is filled with a viscous, frozen product.

LF Filling Machine

LF-04/06/08 semiautomatic filling machine for cups & cones have

LF Filling Machine

- Max diameter of cup is 90mm

- Strong stainless steel frame with adjustable legs

- Set of lamellas with 4/6/8 holes for plastic holders (one type of holder included)

- Step-by-step pneumatic/servo lamella drive

- Electronic control panel in IP 65 protection rate, made od AISI 316 stainless steel with electric elements and controls

- Operator panel 8\" LCD touch screen. Screens and labels in English/local language

- Filling station made of 4/6/8 time-elapse filling heads, single color, with adjustable filling volume. Vertical movement of filling station on pneudrive (servodrive on request).

- Lifting station on outlet, for easy discharge of finished products.

- Central PLC computer OMRON

- Pneumatic components FESTO

WT Filling Machine

WT series are semiautomatic filling machines with high flexibility

WT Filling Machine

- Large variety of ice cream products: cones, cups, containers, bulk and cakes.

- All product settings stored in PLC

- Easy change-over between products

- Open design

- Strong stainless steel frame with adjustable legs

- Operator panel 8\" LCD touch screen. Screens and labels in English/local language

- Step-by-step movement of trays by servodrive

- Filling station made of 1/2/4/8 time-elapse filling head/s. Vertical movement of filling station on servodrive

- Pencil filler

- Topink decoration

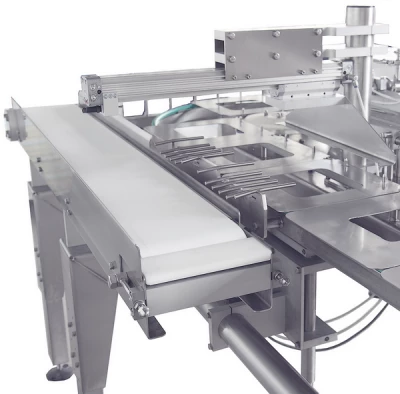

- Product discharge belt

DU Filling Machine

Stand-alone filler designed for filling ice cream semi-automatically with or without inclusions into “family bulk” containers - rectangular, square or round, or ice cream decorated cakes. It can operate both with ice-cream or with creamy products. It is completely made of stainless steel and of anodized light alloy. Every part that comes into contact with the product is made of materials according to the current sanitary and hygienic lows. It works electro pneumatically.

DU Filling Machine

- Supporting framework.

- Time filler with pneumatic cylinder.

- Control electric panel. Panel and labels in English/local language.

- Control filling cylinder.

- Working table.

- Pressure reduction gear filter unit.

- Working table adjusting clamps.

- Filler vertical translation. servomotor and detachment.

- Connections to product to be filled with variegation (syrup).

- Pneumatic components FESTO.