Horizontal Compact Flow Wrapper

Horizontal Compact Flow Wrapper Machine is entry level for flow wrapper with compact design and reasonable price, suitable for packaging product simple or similar size. Applicable in most product you can imagine inside a wrapper, masks, pet food, bread, cakes, moon cakes, instant noodles, biscuits, snacks, pastry products, productive wrapping of boxed products, candy, blisters, cosmetics products, toy industry, cards and many more.

Horizontal Compact Flow Wrapper

- Compact construction for reducing space and cost requirement

- Bag length is easy adjusted by the indicator

- Equipped with precision photocell sensor for tracing control

- Auto-stop for out of film

- Efficiently working performance and labor saving

- All product-contacted areas are in stainless steel or plastic construction

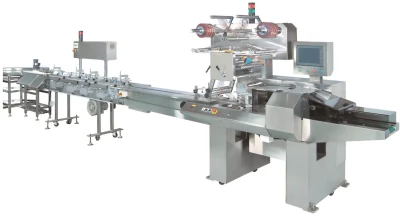

Horizontal Automatic Packaging Machine

Horizontal Automatic Packaging Machine reduces labor costs while maintaining high productivity output on long and continuous operation. The most notable feature of this packaging machine is its regimented processing of products. Its inline feeder offers high flexibility to the packaging line. Multiple belt conveyor system with automatic control of the speed of each belt enhances the capacity and efficiency. The speed of inline feeder is synchronized to the flow wrapper by the vacuum belt driven by the servo motor. The system is used for high speed inline feeding of regular shaped product such as cookies ,chocolate bars. etc. Applicable products includes the following but are not limited to Cake, Chocolate, Credit Card, Ice Cream, Biscuit, Frozen Food and similar products.

Horizontal Automatic Packaging Machine

- Durable, high productivity and low-noise by 4 independent servo motors with electronic control enable 24hours nonstop high speed packaging

- User-friendly human / machine interface control with 10.4inch colorful monitor and Dialogue type screen provides maximum operational convenience and is easy to learn

- Comply with PIC/S-GMP specification and also equips USB port and automatic saving event log

- 50 sets of recipe (bag length, temperature, speed, feeding position, film tension and cutting position) could reduce the initial lose providing high efficiency

- High compatibility with different feeding systems: Desiccant dispenser, Card Magazine, Product Orientation Systems (for round product), Row distribution systems (for bar-shape product) and belt type feeding system... etc.

- Optional to (a) Auto Splicer (b) bar code reader (c) Rejection function