- Home

- Industries

- Food

- Burger

Burger Equipment

A hamburger is a food, typically considered a sandwich, consisting of one or more cooked patties usually ground meat, typically beef placed inside a sliced bread roll or bun. The patty may be pan fried, grilled, smoked or flame broiled. We offer only the best burger processing equipment. Increase yield by integrating RGMTSI burger equipment to your production line today.

The ProLeaver 26300

The ProLeaver 26300 is the most compact stand-alone paper feeder in the world. It can be configured to only add 30” in length to your food processing line and still interleave up to 26” wide paper or up to 6 lanes of narrower paper.

The ProLeaver 26300

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

The ProStax DS 6 & 13 Drop Stacker

The ProStax DS Drop Stacker is designed to interface with our 100 Series ProLeavers. Its compact design means it can fit into almost any food production operation and its pneumatic motion control means it’s easy and affordable to maintain. The DS counter/stacker is equipped with an exit conveyor that is configurable in the field for inline discharge or discharge at 90 degrees for a more compact layout. Widths of 6” and 13” and cycle rates up to 100 per minute allow this compact system to produce at a very high level. It is great for automatic food stacking with cheese, pizza crust, flatbreads, raw dough, pressed cheese flats, omelets, deli meats etcetera. It can also be used as a burger stacking machine to load fresh burgers directly into a tray.

The ProStax DS 6 & 13 Drop Stacker

- You thought there was a placeholder text here, but it was me DIO!

The ProStax PS 13 Platform Stacker

The ProStax PS Platform Stacker for our 100 Series ProLeaver is available in 13” width and is designed for short portions, 6” and under in one or two lanes. While all ProStax automatic stacking systems eliminate labor and repetitive motion, the ProStax PS is designed to reduce the drop height of portions when counting and stacking. It’s great for deli meat and cheese.

The ProStax PS 13 Platform Stacker

- You thought there was a placeholder text here, but it was me DIO!

ProLeaver 6100

The ProLeaver® 6100 is an economical, flexible, entry-level automatic food interleaver designed to help manufacturers automate small production lines and allow them to become more competitive in today’s markets.

ProLeaver 6100

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

ProLeaver 13100

The ProLeaver® 13100 and ProLeaver® 13100 Twin Lane offer the same speed, accuracy, and value as the narrower ProLeaver® 6100 but with a wider paper path and the ability to cut two lanes of paper.

ProLeaver 13100

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

The ProLeaver 9300

The ProLeaver 9300 Small Form Factor Interleaver Stacker presents a small footprint that saves space over other automated food interleaving systems that are available. The rugged stainless steel design of each automated food machine meets and exceeds industry sanitation standards. The control and drive enclosures are fully gasketed for 100% wash down capability. The ProLeaver 9300 is also designed to easily interface with your packaging machinery. PLC design allows easy production set-up, changes, and networking with other equipment. The ProLeaver 9300 can provide a single bottom sheet or full-wrap interleaving, while achieving high-speed, fully automatic operation. It can also be outfitted with a remote monitoring and diagnostic system (RMDS). Perfect for burgers, deli meat, bacon, tortillas, cookies, and pasta.

The ProLeaver 9300

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

The ProLeaver 20300

The ProLeaver 20300 features up to 200 rows per minute, up to four lanes of paper, the ability to run paper or plastic film and multiple stacking options.

The ProLeaver 20300

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

ProStax USS Universal Shuttle Stacker

The ProStax USS is the most flexible automated food stacker in the ProStax line-up. While many stackers are focused on long or short portions to achieve maximum speeds, the Universal Shuttle Stacker is built to handle both long and short portions with no changeover. In keeping with its “universal” name the USS is also great for applications that need to run without paper or “bypass” the ProLeaver. By simply turning the ProLeaver and the ProStax into bypass mode, products can be sent over the system without moving line components or adding auxiliary conveyors. Many other ProStax models require paper under portions to perform optimally. ProStax USS can stack products with or without paper.

ProStax USS Universal Shuttle Stacker

- You thought there was a placeholder text here, but it was me DIO!

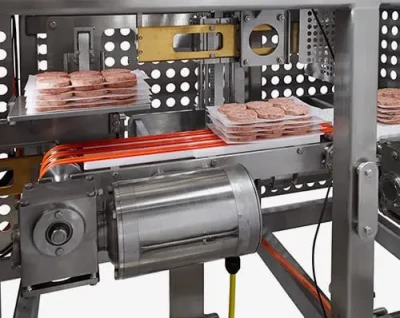

ProStax HPS Homestyle Patty Stacker

The ProStax HPS is specifically designed to count and stack fresh, formed, homestyle hamburger patties that have been interleaved on one of our ProLeaver systems. What really sets the ProStax HPS apart is its ability to drop stacks of burgers directly into trays. Further, at speeds up to 230 patties per minute this high speed stacker outpaces any competing solutions.

ProStax HPS Homestyle Patty Stacker

- You thought there was a placeholder text here, but it was me DIO!

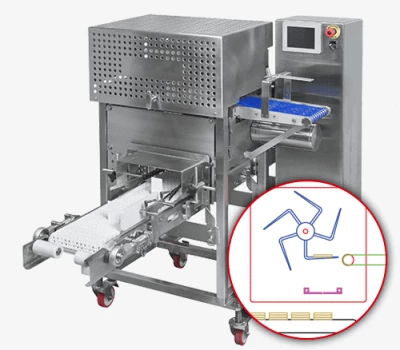

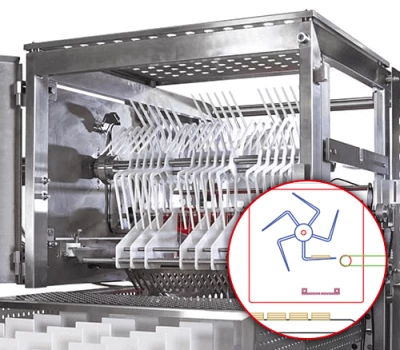

The ProStax FW Ferris Wheel Stacker

The ProStax FW is offered in widths from 9” all the way up to 32” and can handle 1 to 7 lanes of products. This high speed stacker is specifically developed to run portions shorter than 6.5” at speeds up to 280 cycles per minute. When interfaced with one of our ProLeavers, the ProStax FW completes your automation solution by reducing labor and repetitive motion injuries while increasing throughput, uptime, and food safety. The ProStax FW can be equipped with a 90 degree stack discharge conveyor to singulate finished stacks for easy feeding of flow wrapper or packaging machine. Or you can add an optional bypass for when you want to run product that doesn’t need to be interleaved or stacked.

The ProStax FW Ferris Wheel Stacker

- You thought there was a placeholder text here, but it was me DIO!