- Home

- Industries

- Pharmaceutical

- Ampoule

Ampoule Equipment

An ampoule is a small sealed vial which is used to contain and preserve a sample, usually a solid or liquid. Ampoules are usually made of glass. Modern ampoules are most commonly used to contain pharmaceuticals and chemicals that must be protected from air and contaminants. RGMTSI ampoule filling and sealing machines accommodate a range of products from aqueous solutions to powders and even pellet applications. These high-speed ampoule filling and sealing machines are versatile, compact, and self-contained. These features, along with the accessibility of parts and minimal changeover time contribute to the successful operation of these machines.

Ampoule and Vial Blister Cartoning Line

Ampoule and Vial Blister Cartoning Line offers a perfect solution for ampoules and vials packaging. Featuring robust robotic system, the Ampoule and Vial Blister Cartoning Line aims to improve and optimize efficiency at every stage in the blister packaging process. With an optional YAMAHA 4 or ABB 6 robot feeders, expect accurate and consistent blister cavity feeding and sealing. This blister cartoning line adopts an independent PLC with advanced touchscreen HMI, while the electrical systems are mainly OMRON, SMC or Leybold. The modular design and easy part changeover makes it easy to adopt Ampoule and Vial Blister Cartoning Line for a range of ampoules and vials packaging. To ensure safety, all moving parts and processing sections of blister packing line feature a safety cover with an auto stop mechanism. The Ampoule and Vial Blister Cartoning Line also features a stainless steel structure, as per the cGMP requirements, with a robust and stable structure. Easy to clean surface with virtually no dead angle meets the hygienic requirements in the pharmaceutical and food processing industries. Ampoule and Vial Blister Cartoning Line can be customized for specific pharmaceutical needs.

Ampoule and Vial Blister Cartoning Line

- Max output: 300 -400 ampoules/minute; 160-240bottles/minute

- Fully integrates machine with blister packaging and cartoning machine

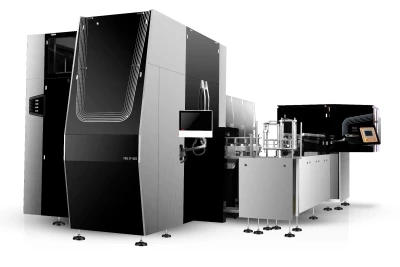

Blow Fill Seal Machine

BFS (Blow-Fill-Seal) system is innovative technique which is capable of blow molding, aseptically filling, and sealing in one continuous operation. A direct-blow molding technology is incorporated with the time pressure-enhanced filling machine that allows forming the containers and filling solutions simultaneously. Extrusion: The plastic tube extruded from the granules is fed into the opened blow mold. Moulding: The main mold closes, sealing the base in the process. The mandrel is lowered onto the neck of the mold and uses compressed air to blow the tube section into the container shape. Small containers are molded with a vacuum. Filling: The container is filled with the precise product amount as measured by the dosing system, again via the mandrel. Sealing: The mandrel is removed, the head mold closes, and the required closure is formed by a vacuum. Demoulding: The blow mold opens, the container leaves the machine, and the next cycle begins. A conveyor system takes the container to the next processing stage.

Blow Fill Seal Machine

- Shatterproof plastic containers

- Ideal for the aseptic filling of liquids and gels

- Maximum safety due to ISO Class 5 conditions at the filling point

- Officially recognized as an advanced aseptic system

- Fully automatic manufacture, filling, and sealing in a single process

- Maximum process and product reliability

- Maximum filling precision

- Virtually unlimited scope in terms of container design

- Customizable to different uses and dosage forms

- Modular design for easy separation of gray and white system zones