- Home

- Industries

- Slaughter Line

- Beef

Beef Equipment

Beef is the culinary name for meat from cattle. In prehistoric times, humans hunted aurochs and later domesticated them. Since then, numerous breeds of cattle have been bred specifically for the quality or quantity of their meat. Today, beef is the third most widely consumed meat in the world, after pork and poultry. RGMTSI provides and maintains high-quality slaughter solutions along with cutting and deboning lines for cattle and veal. Our solutions are efficient, robust, ergonomic, hygienic, food safe and innovative.

Tongue Bone Cutter

Pneumatically powered cutter for cutting beef tongue bones.

Tongue Bone Cutter

- Ideal for cutting the hyoid bone – in all size kills.

- Reduces operator fatigue caused by tongue bone clipping with hand shears.

- Lightweight and small for maneuverability.

- Cuts accurately and quickly – no bone splinters.

- Robust and durable construction for long, trouble-free life.

- Anti-tie down controls for operator safety

Steam Vacuum System

Steam Vacuum System Model CV-1 for the reduction of pathogens and the removal of spinal cords on beef, hogs and sheep.

Steam Vacuum System

- The CV-1 is specifically designed for pathogen reduction and the spinal cord removal on the carcasses of beef, pork and lamb.

- Increases shelf-life by reducing the amount of bacteria found on the carcass.

- Increases yields – less trimming required.

- Lightweight handpiece for optimum operator comfort.

- High vacuum – for fast removal of contamination and spinal cords.

- Different nozzles for specific applications.

- All stainless construction for maximum hygiene.

- USDA approved.

Spinal Cord Sheath and Mis Split Remover

SHC 165G spinal cord and mis-split remover for beef or pork.

Spinal Cord Sheath and Mis Split Remover

- Latest patented technology for grinding away BSE risk material, including the spinal cord, which is under the mis-split, and the meninges (spinal cord).

- Connected to a vacuum system that collects removed spinal cord material for disposal.

- Lightweight, powerful (2.5 hp) hydraulic motor – no bogging down or motor icing; low noise and instant stop.

- Heavy duty gears made to withstand the extreme conditions found in larger meat processing plants.

- Rugged construction provides unsurpassed durability.

- Meets national and international requirements for hygiene and safety.

SUSPENTEC Particle Reduction System for Injection Processes

Used worldwide to process roast beef, ham, turkey breast, chicken products, steaks, fish, bacon and various other whole-muscle products, the patented SUSPENTEC process has brought significant profit building advantages to users everywhere. Hundreds of processors of fresh, cooked, refrigerated or frozen meats and seafood worldwide are using the SUSPENTEC system to add value to their products while lowering their costs of finished goods. An application-customized SUSPENTEC system inject lower cost protein materials into higher cost whole muscle products. Enhanced binding, reduced cook and chill shrink and increased slicing yields are just a few benefits realized. The heart of the SUSPENTEC process lies in its high-throughput, precise, MultiCut reduction system where the mixture recirculates through the reduction unit and mixing hopper until it becomes a homogeneous mixture of brine and ultra fine particles of meat. When exact particle size or temperature is achieved, a divert valve automatically directs suspension to feed one or two holding hoppers. An optional chiller maintains the critical suspension temperature. From the holding hopper(s), a pump delivers suspension to a standard injector. Whole muscle product is then injected with the suspension to the preset yield gain. Excess suspension from the injector is captured by a return hopper and reprocessed. The modular and compact SUSPENTEC system is adaptable to practically any plant layout.

SUSPENTEC Particle Reduction System for Injection Processes

- SUSPENTEC system consists of Mixing hopper with MultiCut reduction unit, Holding hopper(s) with optional chiller(s), Return hopper from injector, Return reduction unit (optional).

- The process involves mixing a brine solution with lower cost materials such as trimmings, rework, etc. and injecting mix into more costly whole muscle product.

- The modular SUSPENTEC system is adaptable to each unique application depending on plant layout and space considerations.

- Increased bind, reduced cook and chill shrink, increased slice yield and lower overall product cost.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Blade Sharpener

RGMTSI offers a sharpening service for all blades we sell and supply with our products, performed by our highly qualified Service Engineers. We recently introduced our NEW circular saw sharpening and blade setting service with advanced technology with machinery that allows us to offer a service second to none for our customers. The services allows you to sharpen all circular saw blades back to their original specifications. You can even customise them to your own company requirements.

Blade Sharpener

- Advanced blade specifications reduce stress, wear and tear on equipment

- Testing has already improved blades by 10% to 20%

- Testing has proven reductions in bone dust

Sheep and Goat Horn Cutter

30CL-3 hydraulic powered horn cutter for sheep, goats and beef nubs.

Sheep and Goat Horn Cutter

- The 30CL-3 is specifically designed for high production removal of sheep and goat horns.The 30CL-3 is specifically designed for high production removal of sheep and goat horns.

- The 30CL-3 will cut beef nubs flush to the skull.

- Effortlessly removes the curliest horns directly on the skull.

- Compact design with pistol grip and stick handles for optimum operator comfort.

- Built tough for long trouble-free operation.

- Anti-tie down controls for operator safety.

- Robust stainless steel construction for best possible hygiene and low maintenance.

- Meets national and international requirements for safety and hygiene.

Pneumatic Stunner

USSS-1 pneumatically operated high speed captive bolt stunner for cattle.

Pneumatic Stunner

- Renders the stunned animal insensible to pain.

- One shot humane stunning procedure. Fires only once – no multiple firing.

- Better stunning for improved meat quality.

- Air operated with no air injection into animal.

- Two hand control for safer operation.

- Easy to handle and safe to operate – low recoil or kickback – less operator fatigue.

- Easy to repair and clean.

- Lightweight – tool only weighs 30 pounds (13.6 kg).

Loin Dropping Bandsaw

Buster V Loin Drop - electrically powered bandsaw for beef loin dropping (quartering).

Loin Dropping Bandsaw

- The high production solution to beef loin dropping.

- Superfast – a single operator handles 900 beef loins per hour.

- Performs the cut on the rail – eliminates removal of beef sides from the rail, reducing manpower requirements.

- Highly accurate – for precise cut positioning.

- No bone splinters.

- Easy to clean for good hygiene.

- Robust construction for long life.

- Anti-tie down controls for operator safety.

Hock Restrainer

BHR-1 hydraulic hock restrainer for beef.

Hock Restrainer

- The BHR-1 relieves trolleys and the rail during hide pulling – eliminating the possibility of pulled tendons, broken trolleys or hooks and fallen carcasses.

- Eliminates kill floor down-time required for re-hanging fallen carcasses.

- Eliminates the resulting contamination from fallen carcasses.

- Reduces wear and tear on trolleys, hooks and rail.

- The BHR-1 is synchronized with the line for fully automated operation.

- No operator is required.

- Automatic internal sanitization cycle for hygiene.

- Rugged stainless steel and galvanized construction for long, trouble-free operation.

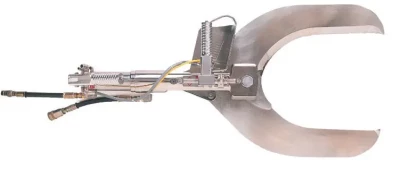

Forequarter and Loin Cutter

50CL hydraulically powered forequarter and loin dropper.

Forequarter and Loin Cutter

- The 50CL quickly and easily severs the loins or forequarters from beef.

- Fast – a single operator can handle up to 400 beef / hour.

- Designed for optimum handling and maneuverability.

- Robust stainless steel construction, including solid stainless steel blades and single piece clevis for best possible hygiene and low maintenance.

- Greasable pivot points for extended life.

- Ant-tie down controls for operator safety.

- Meets national and international requirements for safety and hygiene.