- Home

- Industries

- Food

- Bread

Bread Equipment

Bread is a staple food prepared from a dough of flour and water, usually by baking. Throughout recorded history, it has been a prominent food in large parts of the world. Professional bakeries require commercial-grade equipment. Our bakery ovens come in a range of styles to suit your needs.

BT Inline Depanner

Depanners are specifically designed to remove bread, buns and other products that have seeds or toppings from pans traveling through the baking process. Various sizes and configurations to create the setup that’s right for your operation. Depanner configurations for bread, buns or a combination with manual or automated adjustments.

BT Inline Depanner

- Specially-profiled vacuum chamber for gentle product handling

- Recipe control of conveyor speeds

- Powered vacuum head height adjustment

- Easy handwheel adjustments.

- Simple, operator friendly HMI control screens

- Cantilevered head for easy operator-side vacuum belt removal.

- Remote vacuum blower for lower noise.

- Open access design to facilitate inspection, maintenance and sanitation.

- Minimal horizontal surfaces to reduce collection of debris.

EL54C Entry Level Twist Tyer System

The Model EL54C Twist Tyer delivers the #1 consumer preferred closure at a lower cost per package for the retail and small wholesale bakery. For optimal performance a minimum bag thickness of 1.25mil is required. It is designed to be used with manual or semi-automatic bag loaders to improve the efficiency of the bakery packaging process. With the Entry Level Twist Tyer System, packages are simply placed onto the conveyor and from that point on the feeding and tying process is automated.

EL54C Entry Level Twist Tyer System

- Most economical closure

- Portable system

- Simple operator controls

- Flighted conveyor

- Low maintenance

- Electric requirements: 110 VOLT, 50/60 HZ, 1 PHASE, 10 AMPs

- Optional: Hand bagger, Blower Kit

2000 Servo Twist Tyer

This user friendly twist tyer has them all beat. The 2000 model offers automatic timing, modular design, package recognition, and easy threading. With no down time needed for lubrication, and 100+ bags per minute, the sooner your up and running with this twist tyer, the sooner you’ll be saving money! There’s so much that this twist tyer can do. Learn more by speaking with an RGMTSI expert now.

2000 Servo Twist Tyer

- Package recognition system

- Quick, easy threading

- Multiple applications

- Up to 100 bags per minute

- Simple operator controls

- Electric requirements: 110 volts 60 hz 1 phase, 10 AMPS

- Optional: Digital display, Package detection system, Portable Stands, Speed follow kit, Bag vacuum kit, Blower kit, Conveyor

2000VT Vertical Servo Twist Tyer

The Model 2000VT twist tyer is uniquely designed to tie bags in the upright position at high speeds. A wide variety of applications can be solved with this highly flexible servo twist tyer. It has automatic timing, height adjustable, easy threading and needs very little down time.

2000VT Vertical Servo Twist Tyer

- Package recognition system

- Quick, easy threading

- Multiple applications

- User friendly controls

- Electric requirements: 110 volts 60 hz single phase, 10 AMPS

- Optional: Digital Display, Package Detection System, Extended infeed belts (VTRE), Conveyor

ASC Ambient Spiral Cooler

Using ambient air, the Ambient Spiral Cooler (ASC) reduces the internal heat of food products immediately after they exit e.g. a baking oven. The ambient cooler is often used in the baking industry as a pre-cooler before the bread products enter a descending spiral freezer.

ASC Ambient Spiral Cooler

- Belt width up to 1500 mm

- Single drum or twin drum spiral

- Steel spiral belt

- Stacking or non-stacking spiral belt

- Can be adapted with fans for optimizing the cooling efficiency

- Multiple drive motors

- Recipe-controlled for easy operation

- Flexible design with multiple layout options

- Manufactured in stainless steel with open profiles for easier cleaning

Dough Expert

The Dough Expert dough dividers are known for their reliability, weight accuracy and flexibility. Suitable for a wide range of dough processes and can accurately handle products of different weights and capacities. It can be used to easily measure dough for grilled sandwiches, biscuits, French bread, rye bread, panettone, brioche and pizza.

Dough Expert

- Multiple dividing technologies in-house to control the dough.

- Low cost of ownership.

- Custom setup.

- Many functions included in the standard configuration.

- Easy to clean and maintain.

- High safety standard during use and when cleaning.

- Each unit is tested with dough before delivery.

- Workhorse among the dough dividers.

- Robust and industrial.

- Basic version or touchscreen machine.

- Different pocket configurations available.

- Numerous options available.

- Also developed in an open C-Frame version.

Infeed Systems

Each system is supplied customized to the specific production and is fully synchronized with the weigher. This ensures a steady and uniform feed flow in accordance with the specified capacity requirements.

Infeed Systems

- You thought there was a placeholder text here, but it was me DIO!

Horizontal Standard Flow Wrapper

The Horizontal Standard Flow Wrapper Machine has the merit of both mechanical and digital control, product changeover easily, colored HIM for key in data also able to cope with semi-auto feeding to increase the packaging speed. Applicable in most product you can imagine inside a wrapper, masks, pet food, bread, cakes, moon cakes, instant noodles, biscuits, snacks, pastry products, productive wrapping of boxed products, candy, blisters, cosmetics products, toy industry, cards and many more.

Horizontal Standard Flow Wrapper

- User-friendly human machine interface control with 4.3inch touch screen for convenient operations

- Compact construction for reducing space required

- Bag length indication ensures fast and accurate length adjustment

- Optional feeding systems are available for various products

- Equipped with precision photocell sensor for film tracing control

- The machine stops automatically when the film runs out

- Four sets of temperature controllers

- All product-contacted areas are in stainless steel or plastic construction

Horizontal Compact Flow Wrapper

Horizontal Compact Flow Wrapper Machine is entry level for flow wrapper with compact design and reasonable price, suitable for packaging product simple or similar size. Applicable in most product you can imagine inside a wrapper, masks, pet food, bread, cakes, moon cakes, instant noodles, biscuits, snacks, pastry products, productive wrapping of boxed products, candy, blisters, cosmetics products, toy industry, cards and many more.

Horizontal Compact Flow Wrapper

- Compact construction for reducing space and cost requirement

- Bag length is easy adjusted by the indicator

- Equipped with precision photocell sensor for tracing control

- Auto-stop for out of film

- Efficiently working performance and labor saving

- All product-contacted areas are in stainless steel or plastic construction

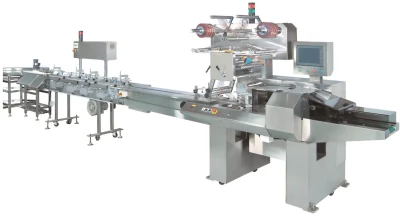

Horizontal Automatic Packaging Machine

Horizontal Automatic Packaging Machine reduces labor costs while maintaining high productivity output on long and continuous operation. The most notable feature of this packaging machine is its regimented processing of products. Its inline feeder offers high flexibility to the packaging line. Multiple belt conveyor system with automatic control of the speed of each belt enhances the capacity and efficiency. The speed of inline feeder is synchronized to the flow wrapper by the vacuum belt driven by the servo motor. The system is used for high speed inline feeding of regular shaped product such as cookies ,chocolate bars. etc. Applicable products includes the following but are not limited to Cake, Chocolate, Credit Card, Ice Cream, Biscuit, Frozen Food and similar products.

Horizontal Automatic Packaging Machine

- Durable, high productivity and low-noise by 4 independent servo motors with electronic control enable 24hours nonstop high speed packaging

- User-friendly human / machine interface control with 10.4inch colorful monitor and Dialogue type screen provides maximum operational convenience and is easy to learn

- Comply with PIC/S-GMP specification and also equips USB port and automatic saving event log

- 50 sets of recipe (bag length, temperature, speed, feeding position, film tension and cutting position) could reduce the initial lose providing high efficiency

- High compatibility with different feeding systems: Desiccant dispenser, Card Magazine, Product Orientation Systems (for round product), Row distribution systems (for bar-shape product) and belt type feeding system... etc.

- Optional to (a) Auto Splicer (b) bar code reader (c) Rejection function