- Home

- Industries

- Food

- Batter

Batter Equipment

Batter is a flour mixture with liquid and other ingredients like sugar, salt and leavening. Batter is most often used for pancakes, light cakes, and as a coating for fried foods. Need anything related to batter? Be it filling or mixing, we got it all.

SP 64 / 2P 64 Single & Dual Piston Fillers

Single and Dual Piston Fillers – SP 64 / 2P-64 are the classic workhorses of the food processing industry. They are easy to clean and operate, and are versatile and gentle on all products and provide immediate cost-saving results. Large port openings permit filling of chunky ingredients without crushing. These labor-saving single piston fillers and depositors improve your quality and consistency when depositing large, delicate particulates without damaging the particulate. Great for accurate filling or depositing into trays, bottles, cans, pouches, or targeted spot depositing.

SP 64 / 2P 64 Single & Dual Piston Fillers

- Fill from a fraction of an ounce to 64 oz’s per piston.

- Stainless steel construction and food-approved contact parts.

- Air powered (check for air requirements).

- Pneumatic dump system / interlocked safety cover.

- Lift-Off metering piston for rapid sanitizing.

- Easy height adjustment (14″ adjustment).

- Locking heavy duty swivel casters.

- Enhanced operator friendly safety cover.

SP 160 Single & 2P 160 Dual Piston Filler / Depositors

SP-160 Single & 2P-160 Dual Piston Filler / Depositors are especially designed for the institutional packer. These are classic workhorses of the food processing industry. Easy to clean and operate and versatile and gentle on all products, providing immediate cost-saving results. Large port openings permit filling of chunky ingredients without crushing. Because of the large port openings and gentle internal passages, these machines are ideal for delicate products such as 4+1 sliced or whole straw-berries, fruit fillings, deli salads and vegetable fillings. These machines are available in several different sizes and configurations to match the throughput requirements. Additional further automation is also available such as container denesters, lidders, sealers and transfer pumps.

SP 160 Single & 2P 160 Dual Piston Filler / Depositors

- Locking swivel casters

- Air powered – consult factory for compressed air requirements

- 8-14 inches of height adjustment

- Stainless steel construction with all contact parts of food-approved materials

- Fills from fractions of an ounce to 160 ounces per piston with change cylinders

- Pneumatic dump system with interlocked safety cover

Multi Piston Filler with Diving / Traveling Spout Bridge

Multi-Piston Filler with Diving / Traveling Spout Bridge is designed for use over continuous motion entree or pie lines. Optional features include PLC control, large port openings, tilt hopper for easy sanitizing, thrustless actuator for the product valve and drop-down pneumatics to make maintenance easier. Many hoppers are available, including a U-hopper with variable speed horizontal helical agitation. Spouting is either rotary shut-off or vertical blow-off and bridge can travel either with the target or over/under run for spreading. Traveling spout bridge is either line shaft or servo driven.

Multi Piston Filler with Diving / Traveling Spout Bridge

- You thought there was a placeholder text here, but it was me DIO!

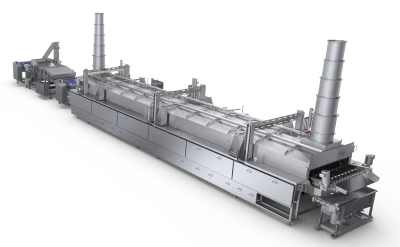

Batter, Breading, And Frying Lines

RGMTSI offers fully integrated Batter, Breading, and Frying lines. Each machine in the line can be controlled from a single HMI Panel, giving one operator complete control over several pieces of equipment. Lines can be customized to fit your processing needs by utilizing our batter and equipment in any order you choose.

Batter, Breading, And Frying Lines

- You thought there was a placeholder text here, but it was me DIO!

VCS Batter Mixer

Batter Mixer

VCS Batter Mixer

- Ultrasonic in-line viscometer controlling a wide range of viscosities with extremely tight tolerances. No calibration required. CIP capable

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Fully automated controls using an AB PLC & color touchscreen for 100% automated control of batter mixing and monitoring

- All stainless steel viscosity pump and motor with direct drive

- Stainless steel 2 HP mixer

- Sanitary stainless steel water piping

- Stainless steel feed pump and motor with direct drive are controlled using variable frequency drives for speed and flow control

- Ergonomically designed low profile batter hopper available in standard 34” load height with 100 lb. capacity

- Can produce batter with tolerances of less than one-third of a cup second, which equals 5-6 centipoise

- Stainless sanitary piping

- Out-of-spec alarm system monitoring temperature and motor overloads

- Perforated parts basket for all sanitary and pump parts

- High efficiency, stainless steel mix tank w/cooling jacket on exterior of side and bottom of tank (180 PSI A.S.M.E. Certified/Stamped)

TCS Batter Mixer

Batter Mixer

TCS Batter Mixer

- An ALL electric automated tempura batch mixing system with very precise mix accuracy and temperature control

- Standards & guidelines to Food Safety & USDA requirements

- Construction is all stainless steel frame and assembled using US standard food safety components

- Capable of producing up to 660 gallons of tempura per hour or as little as 25 gallon per hour. The TCS can mix and pump a batch of tempura in 5 minutes or less.

- High efficiency 50 or 70 gallon insulated tanks

- Adjustable batch size that is 100% programmable

- All stainless steel Unibloc PD feed pump with variable speed

- All stainless steel direct driven mixer with precise speed control of a VFD

- All stainless steel water and sanitary piping

- All stainless steel jacketed & insulated mix tank with jackets on side & bottom of tank (180 psi ASME Certified & Stamped)

- Ergonomically designed low profile hopper with 150lb capacity

- Self-diagnostics for alarms, temperatures and motor O.L.

- Perforated parts basket for all sanitary and pump parts during disassembly

Batter Applicator

Batter Applicator

Batter Applicator

- Construction is all stainless steel frame with US Standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Designed for 40” and 52” usable belt width

- Operating controls are ergonomically designed

- Stainless steel centrifugal pump and motor

- 3/8” pitch wire belt with roller discharge

- Locking gas cylinder lift system for ease of sanitation and safety

- Top submerge conveyor with separate direct drive for ease of cleaning and maintenance

- Includes one top blower tube above and below product belt for tie into plant central blower system

- Standard 12” infeed conveyor with mesh belt and separate drive