- Home

- Industries

- Slaughter Line

- Poultry

Poultry Equipment

Poultry are domesticated birds kept by humans for their eggs, their meat or their feathers. These birds are most typically members of the superorder Galloanserae, especially the order Galliformes. RGMTSI offers solutions and services for processing of all usual types of poultry, all possible stages in the process and at any required production capacity. Besides broiler processing, we also specialize in technology and systems for processing turkeys, ducks and other breeds such as layers and parent stock. Our approach focuses on accomplishing the most value adding, tailor made production facilities.

SUSPENTEC Particle Reduction System for Injection Processes

Used worldwide to process roast beef, ham, turkey breast, chicken products, steaks, fish, bacon and various other whole-muscle products, the patented SUSPENTEC process has brought significant profit building advantages to users everywhere. Hundreds of processors of fresh, cooked, refrigerated or frozen meats and seafood worldwide are using the SUSPENTEC system to add value to their products while lowering their costs of finished goods. An application-customized SUSPENTEC system inject lower cost protein materials into higher cost whole muscle products. Enhanced binding, reduced cook and chill shrink and increased slicing yields are just a few benefits realized. The heart of the SUSPENTEC process lies in its high-throughput, precise, MultiCut reduction system where the mixture recirculates through the reduction unit and mixing hopper until it becomes a homogeneous mixture of brine and ultra fine particles of meat. When exact particle size or temperature is achieved, a divert valve automatically directs suspension to feed one or two holding hoppers. An optional chiller maintains the critical suspension temperature. From the holding hopper(s), a pump delivers suspension to a standard injector. Whole muscle product is then injected with the suspension to the preset yield gain. Excess suspension from the injector is captured by a return hopper and reprocessed. The modular and compact SUSPENTEC system is adaptable to practically any plant layout.

SUSPENTEC Particle Reduction System for Injection Processes

- SUSPENTEC system consists of Mixing hopper with MultiCut reduction unit, Holding hopper(s) with optional chiller(s), Return hopper from injector, Return reduction unit (optional).

- The process involves mixing a brine solution with lower cost materials such as trimmings, rework, etc. and injecting mix into more costly whole muscle product.

- The modular SUSPENTEC system is adaptable to each unique application depending on plant layout and space considerations.

- Increased bind, reduced cook and chill shrink, increased slice yield and lower overall product cost.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Brine Mixing System

The Brine Mixing System is ideal for high volume mixing, chilling and storage applications, Now you can prepare meat brines or poultry marinades quickly and efficiently in a controlled system for perfect repeatability, batch after batch. The brine mixing process begins at the dry ingredients hopper which is placed at a convenient height for easy loading. When the hopper valve is opened, a vacuumizing action siphons the precise amount of ingredients into the preparation tank. Once ingredients are inside the tank, a powerful centrifugal pump circulates and homogenizes the mixture. Even hard-to-mix ingredients like phosphates, proteins, gums and starches can be thoroughly homogenized quickly. Stainless steel system with fine sanitary finish throughout. Custom designed storage tanks available in capacities up to 530 gallons (2000 liters).

Brine Mixing System

- Efficient, controlled mixing and chilling of meat brines and poultry marinades. Brines can be prepared as supersaturated solutions, with up to 30% heavy solids.

- Feeds directly to ancillary equipment or storage tanks.

- Capacities: 130 gallons (500 liters), 200 gallons (750 liters) and 260 gallons (1000 liters).

- Optional glycol jacketed cooling system available.

- Single propeller or reduction-head style agitator available to custom fit your application.

- Standard or programmable Allen-Bradley controls.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Meat Tenderizer

Meat Tenderizer is one of the most important components in the production of boneless cooked products such as ham, shoulder, chicken or other meats. A conveyor feeds product to a set of rollers equipped with circular knives. This effectively increases the meat surface and opens the muscle tissue, boosting liquid retention and promoting higher concentration of protein at the surface after massaging. The rollers are designed for easy sanitation and do not need to be disassembled to clean the knives.

Meat Tenderizer

- Used for boneless cuts of pork, beef, chicken, or turkey

- Increases the absorption capacity of meat by opening muscle fibers and exposing inner meat surfaces.

- Increases the quantity of muscle protein on meat surfaces for further processing.

- Rollers equipped with circular knives.

- Accommodates product up to 3-1/8" (80 mm) thick.

- Open design of knife roller for easy sanitation.

- Optional hopper for loading product onto conveyor.

Slice Right Slitter

With the growing demand to utilize large bird breast meat, RGMTSI Equipment is pleased to offer an excellent solution to meet your needs. The RGMTSI Slice Right Slitter offers the ability to accurately and consistently slice large breast meat into multiple slices of controlled thickness. The Slice Right Slitter has a lower purchase price, with low operating cost, and is an easy to maintain piece of equipment, making it a preferred choice over the competition. If you are looking to increase yield, water cutting accuracy, or decrease the M&R on your current operation, we encourage you to call your RGMTSI Equipment representative and begin saving money and experiencing a superior options, immediately.

Slice Right Slitter

- Dual lane oscilating blade design

- Highly accurate and consistent

- Multiple blade configurations

- Top trim removal

- E-Stop & mechanical SureLok safety system

- Easily adjustable slit heights

- Simple maintenance & sanitation design

- Low water usage

Marination System

As the critical starting point for your further processing lines, consistent marination is essential for your success. RGMTSI is pleased to offer a fully integrated brine marination mixing system. By utilizing high shear mixing options, automatic ingredient loading, recipe controls,heat exchangers, and temperature controls, RGMTSI's Master Marination System is the fully integrated solution for all you marination mixing needs.

Marination System

- You thought there was a placeholder text here, but it was me DIO!

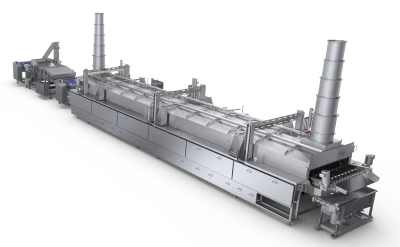

Batter, Breading, And Frying Lines

RGMTSI offers fully integrated Batter, Breading, and Frying lines. Each machine in the line can be controlled from a single HMI Panel, giving one operator complete control over several pieces of equipment. Lines can be customized to fit your processing needs by utilizing our batter and equipment in any order you choose.

Batter, Breading, And Frying Lines

- You thought there was a placeholder text here, but it was me DIO!

DuoMax

Many in the industry are in the predicament of switching equipment around constantly to setup for different products. One of these switches involves moving an inline or flat breader and switching it for a drum breader for their homestyle products. The DuoMax was designed to eliminate the need to move around equipment. It works as both a flat breader and a drum breader and easily switches between the two different modes for maximum efficiency. Inside the DuoMax is an adjustable conveyor attached to three drums. The conveyor can be put in the up position for flat breading and moved to the down position for homestyle products. The drums are easily removable for sanitation and the hood can be disassembled for ease of maintenance. The entire system is controlled by an HMI screen using a recipe based program. If you desire to make better use of the time normally used to switch out equipment, contact us about the DuoMax today!

DuoMax

- You thought there was a placeholder text here, but it was me DIO!

VCS Batter Mixer

Batter Mixer

VCS Batter Mixer

- Ultrasonic in-line viscometer controlling a wide range of viscosities with extremely tight tolerances. No calibration required. CIP capable

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Fully automated controls using an AB PLC & color touchscreen for 100% automated control of batter mixing and monitoring

- All stainless steel viscosity pump and motor with direct drive

- Stainless steel 2 HP mixer

- Sanitary stainless steel water piping

- Stainless steel feed pump and motor with direct drive are controlled using variable frequency drives for speed and flow control

- Ergonomically designed low profile batter hopper available in standard 34” load height with 100 lb. capacity

- Can produce batter with tolerances of less than one-third of a cup second, which equals 5-6 centipoise

- Stainless sanitary piping

- Out-of-spec alarm system monitoring temperature and motor overloads

- Perforated parts basket for all sanitary and pump parts

- High efficiency, stainless steel mix tank w/cooling jacket on exterior of side and bottom of tank (180 PSI A.S.M.E. Certified/Stamped)

TCS Batter Mixer

Batter Mixer

TCS Batter Mixer

- An ALL electric automated tempura batch mixing system with very precise mix accuracy and temperature control

- Standards & guidelines to Food Safety & USDA requirements

- Construction is all stainless steel frame and assembled using US standard food safety components

- Capable of producing up to 660 gallons of tempura per hour or as little as 25 gallon per hour. The TCS can mix and pump a batch of tempura in 5 minutes or less.

- High efficiency 50 or 70 gallon insulated tanks

- Adjustable batch size that is 100% programmable

- All stainless steel Unibloc PD feed pump with variable speed

- All stainless steel direct driven mixer with precise speed control of a VFD

- All stainless steel water and sanitary piping

- All stainless steel jacketed & insulated mix tank with jackets on side & bottom of tank (180 psi ASME Certified & Stamped)

- Ergonomically designed low profile hopper with 150lb capacity

- Self-diagnostics for alarms, temperatures and motor O.L.

- Perforated parts basket for all sanitary and pump parts during disassembly

MP115 Flat Breader

Flat Breader

MP115 Flat Breader

- Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

- Flour coating configuration

- Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

- MP rotating top flow breading distribution system

- Standard casters with stainless steel frame and Phenolic Wheels

- Rotating belt vibrator

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

- Positive cam/lock on all access doors

- Lift cylinder on discharge chute, hopper and covers

- Adjustment/support for discharge of batter applicator

- Belt tension adjustment for hopper/main belt

- Stand-off bearings for maximum sanitary design

- Engineered for safety, user friendliness and optimum uptime

- Operator controls ergonomically designed

- Designed for 40” and 52” usable belt width