- Home

- Industries

- Food

- Ready Meal

Ready Meal Equipment

A frozen meal, prepackaged meal, ready-made meal, ready meal, frozen dinner, and microwave meal is a packaged frozen meal that comes portioned for an individual. A frozen meal in the United States and Canada usually consists of a type of meat for the main course, and sometimes vegetables, potatoes, and/or a dessert. RGMTSI equipment provides machinery and processing lines for ready-to-eat and prepared food processing applications.

SP 64 / 2P 64 Single & Dual Piston Fillers

Single and Dual Piston Fillers – SP 64 / 2P-64 are the classic workhorses of the food processing industry. They are easy to clean and operate, and are versatile and gentle on all products and provide immediate cost-saving results. Large port openings permit filling of chunky ingredients without crushing. These labor-saving single piston fillers and depositors improve your quality and consistency when depositing large, delicate particulates without damaging the particulate. Great for accurate filling or depositing into trays, bottles, cans, pouches, or targeted spot depositing.

SP 64 / 2P 64 Single & Dual Piston Fillers

- Fill from a fraction of an ounce to 64 oz’s per piston.

- Stainless steel construction and food-approved contact parts.

- Air powered (check for air requirements).

- Pneumatic dump system / interlocked safety cover.

- Lift-Off metering piston for rapid sanitizing.

- Easy height adjustment (14″ adjustment).

- Locking heavy duty swivel casters.

- Enhanced operator friendly safety cover.

SP 160 Single & 2P 160 Dual Piston Filler / Depositors

SP-160 Single & 2P-160 Dual Piston Filler / Depositors are especially designed for the institutional packer. These are classic workhorses of the food processing industry. Easy to clean and operate and versatile and gentle on all products, providing immediate cost-saving results. Large port openings permit filling of chunky ingredients without crushing. Because of the large port openings and gentle internal passages, these machines are ideal for delicate products such as 4+1 sliced or whole straw-berries, fruit fillings, deli salads and vegetable fillings. These machines are available in several different sizes and configurations to match the throughput requirements. Additional further automation is also available such as container denesters, lidders, sealers and transfer pumps.

SP 160 Single & 2P 160 Dual Piston Filler / Depositors

- Locking swivel casters

- Air powered – consult factory for compressed air requirements

- 8-14 inches of height adjustment

- Stainless steel construction with all contact parts of food-approved materials

- Fills from fractions of an ounce to 160 ounces per piston with change cylinders

- Pneumatic dump system with interlocked safety cover

Ready Meal Depositors & Fillers

4P-01 is designed for high speed depositing of sauce pellets for meal kits and also for the high speed depositing of sauce, condiments and fillings into thermo formed cavities of horizontal vacuum formers or pre made cups. Speeds to 5700 portions per minute are attainable depending on viscosity. The 4P-01 utilizes a servo driven orbital spout bridge that follows the packages or platens during the fill cycle for increased spout time. Positive shut off spouts are used for clean accurate filling and the filler can be Cleaned-In-Place (CIP) or the design allows for the filler to be quickly disassembled for sanitizing for maximum up time and yield. State of the art controls allow for the fill parameters to be automatically set by simply selecting the recipe or SKU in the operator interface (HMI). Please contact RGMTSI for additional information.

Ready Meal Depositors & Fillers

- You thought there was a placeholder text here, but it was me DIO!

Multi Piston Filler with Diving / Traveling Spout Bridge

Multi-Piston Filler with Diving / Traveling Spout Bridge is designed for use over continuous motion entree or pie lines. Optional features include PLC control, large port openings, tilt hopper for easy sanitizing, thrustless actuator for the product valve and drop-down pneumatics to make maintenance easier. Many hoppers are available, including a U-hopper with variable speed horizontal helical agitation. Spouting is either rotary shut-off or vertical blow-off and bridge can travel either with the target or over/under run for spreading. Traveling spout bridge is either line shaft or servo driven.

Multi Piston Filler with Diving / Traveling Spout Bridge

- You thought there was a placeholder text here, but it was me DIO!

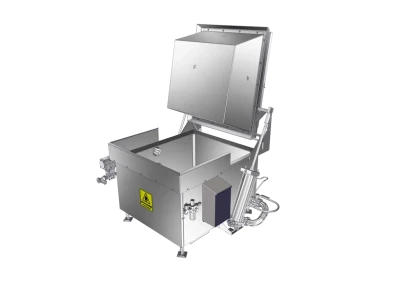

Cooking VAT Chaudix

The Chaudix™ cooking system has been designed to optimize small batch cooking and blanching for the food industry. Its polyvalent, ergonomically and easy to use design provides a cost efficient and food safe solution for Central kitchens, Food service, Food processing.

Cooking VAT Chaudix

- The Chaudix system is an integrated water immersion cooking unit solution with a pneumatic unloading system for the cooking basket. It can be equipped with the Balix system for loading products with European 200 L trolley.

- Ergonomically designed

- Food safety

- Insulated tank with steam proof lid

- Water temperature and level regulation

Kitchenix

The Kitchenix is a fully automated advanced water cook & chill system for Sous Vide cooking technology. It has been specially designed to meet small and medium production needs like Restaurants, Ghost and satellite kitchens and Caterers.

Kitchenix

- The Kitchenix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Kitchenix to suit customer's need

- The Kitchenix system includes Thermix Connect web based controls and mobile app which allow users to monitor overnight cooking without having physical presence on the kitchen.

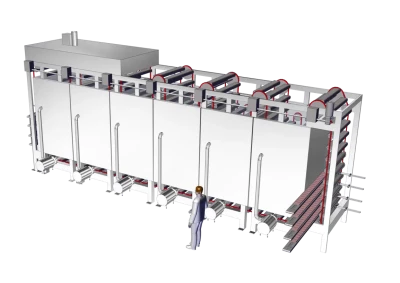

Thermix Sous Vide

Thermix Sous Vide System is a fully automated, advanced water cook & chill process especially design for Sous Vide cooking technology. Industrial food processors can consistently produce guaranteed safe food product of the best quality at highest yields. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope.

Thermix Sous Vide

- Thermix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Thermix to suit customer's need

- The automated Thermix Sous Vide System works continuously at a steady pace of 0.5 to 5 tons per hour with various levels of automation delivering a constant flow of superior-quality products with minimal human labor involvement. The system streamlined design results in exceptionally low maintenance costs

Pico Thermix

The Pico-Thermix is by far the smallest unit that we developed with our industrial customers to perform R&D tests with the same level of expertise that the Thermix solution provides. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope. Sous Vide offers the longest shelf life for natural and tasty products without preservatives, resulting in benefits for all users. The Pico-Thermix system flexible, unique design and controls allows processing a variety of products. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

Pico Thermix

- Undisputed quality

- Food safety & traceability

- Integrated heating & chilling

- Best consistency & clean label

- Batches of 4-6kg | 11lbs

- Advanced recipe controls

- Complete traceability plotting

- Remote web-based monitoring Thermix™ Connect

- Suited for 220/50Hz and 220V/60Hz

- No plant utility required. Works perfect at home.

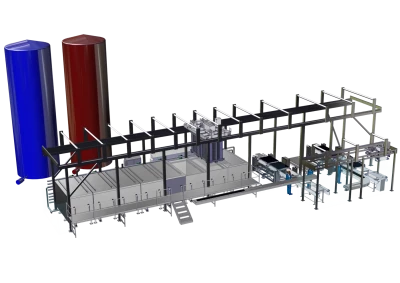

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

RP 25 Horizontal Form Fill Seal Packager

With the RP-25, you get high capacity for a smaller investment. This unit processes 60 packages per minute, with fast changeover time.

RP 25 Horizontal Form Fill Seal Packager

- 100% Stainless Steel Frame

- Pre-mounted Weldment

- Side Extractable Tooling

- Transport Chain - Gripper Opening Sequence

- Allen Bradley Controllogix System

- Cutting: Contour Cutting, Flying Knife Cross-Cutting System, Guillotine Knife Cross-Cutting System, Trim Strip Punch, Rotary Knife System, Rotary Shear Cut, Squeezing Knife Assembly

- Sealing: Rapid Change Seal Bar System, Die Closing System

- Film: Film Mandrels, Unwind Systems, Forming System