- Home

- Industries

- Pharmaceutical

- Ampoule

- Blow Fill Seal Machine

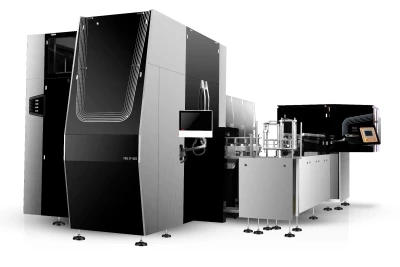

Blow Fill Seal Machine

BFS (Blow-Fill-Seal) system is innovative technique which is capable of blow molding, aseptically filling, and sealing in one continuous operation. A direct-blow molding technology is incorporated with the time pressure-enhanced filling machine that allows forming the containers and filling solutions simultaneously. Extrusion: The plastic tube extruded from the granules is fed into the opened blow mold. Moulding: The main mold closes, sealing the base in the process. The mandrel is lowered onto the neck of the mold and uses compressed air to blow the tube section into the container shape. Small containers are molded with a vacuum. Filling: The container is filled with the precise product amount as measured by the dosing system, again via the mandrel. Sealing: The mandrel is removed, the head mold closes, and the required closure is formed by a vacuum. Demoulding: The blow mold opens, the container leaves the machine, and the next cycle begins. A conveyor system takes the container to the next processing stage.

Features

- Shatterproof plastic containers

- Ideal for the aseptic filling of liquids and gels

- Maximum safety due to ISO Class 5 conditions at the filling point

- Officially recognized as an advanced aseptic system

- Fully automatic manufacture, filling, and sealing in a single process

- Maximum process and product reliability

- Maximum filling precision

- Virtually unlimited scope in terms of container design

- Customizable to different uses and dosage forms

- Modular design for easy separation of gray and white system zones

Related Industries

Blow Fill Seal Machine is mostly used in the manufacturing of the following industry products: