- Home

- Nutraceutical

- Packaging Equipment

Packaging Equipment

Once dosage form is in its final form, it must be properly packaged for distribution. Packaging can also come in different forms which determines how products are handled.

Big Bag Fillers

Big Bag fillers are designed to enable flexible big bags to be hygienically filled at a rate of up to 5 Mtonnes/hour. Big Bag fillers are designed to pack a wide variety of powdered products into flexible bags (FIBCs). Features including bag inflation and base compaction maximize the available volume of the bag and result in a stable pack that reduces the risk of spillage and product loss.

Big Bag Fillers

- Single operating station (manual)

- Bag sits on pallet during filling

- Bag range: 1–1.6 m

- Weighing: optional

- Pallet in the packing room, forklift transfer

- No compaction

- No MAP

- No heat sealing.

Semi Automatic Bulk Powder Fillers

Semi-automatic bulk powder fillers are designed to hygienically pack dry free-flowing food, dairy and nutraceutical powders or granulated materials into flexible intermediate bulk containers (FIBC), big/jumbo bags and super sacks. Our Bulk Bag System (BBS) semi-automatic range is capable of accurately filling bulk bags at varying rates up to 12 metric tonnes/hr under hygienic conditions. Utilizing a single automated carriage system, the filled bag is transferred out of the high care area to the low care area where it is placed onto a pallet. This eliminates wooden pallets inside the high care area (high hygiene area). This makes the system ideal for hygienic powder filling operations which are typically found in dairy and food ingredient plants.

Semi Automatic Bulk Powder Fillers

- Single Operating Station – Semi- Aautomatic

- Bag Suspended during filling

- Bag Range 1- 2.2 m

- Weighing during filling

- Bag compaction available

- Bag transfer and place on pallet outside

- No MAP

- No Heat Sealer

- No Heat Sealing

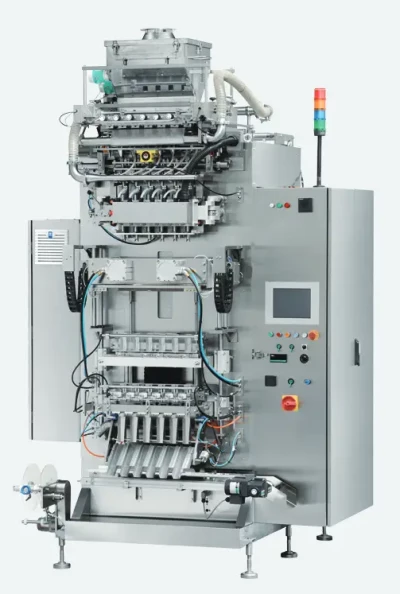

Special Shape High Speed Automatic Multi Lane Packaging Machine

This packaging machine can work with special or customized shape packaging. By utilizing a multi-lane strategy it can pack 30-60 pcs/min/lane, while still being able to do 4 side sealing in unique shapes. Special Shape High Speed Automatic Multi Lane Packaging Machine will be a good addition to optimizing your production line. Special Shape High Speed Automatic Multi Lane Packaging Machine can be use in a wide variety of products across different industries. Some of which can be one of the following but not limited to: Shampoo, Cream, Oil, Sauces, Medicine packaging and so on.

Special Shape High Speed Automatic Multi Lane Packaging Machine

- Applicable Film: PET/AL/PE, PET/VmPET/PE, PET/PE, NY/PE, NY/VmPET/PE, PET/NY/PE, OPP/AL/PE, OPP/VmPET/PE and many other heat-sealable packaging material.

Stick Type Automatic Multi Lane Packaging Machine

Stick Type Automatic Multi Lane Packaging Machine is mainly used for stick type packaging. This packaging machine can be used for food, pharmaceutical and chemical industries. It can also be customized to accomodate 6, 8 or even 10 lanes according to customer's requirements about bag size and filling capacity which greatly improves production output. The packaging machine operation is user friendly, sachet length and production time can be adjusted just by inputiing data. Configuration settings can be saved into templates and can be swapped. This makes Stick Type Automatic Multi Lane Packaging Machine the ultimate packaging machine for your stick type packaging needs.

Stick Type Automatic Multi Lane Packaging Machine

- Built-in safety features

- No operation without compressed air

- Emergency stop control

- Overload protection feature

- Safety door

- Working capacity: 20-70 pcs/min/lane

Liquid and Viscous High Speed Multi Lane Packaging Machine

Liquid and Viscous High Speed Multi Lane Packaging Machine is most suitable for packaging liquid and viscous products. Elegant sachets could be produced by this high speed packaging machine by hot sealing with rollers and 4 side sealing. With high packaging efficiency, application and multi-lane handling, the Liquid and Viscous High Speed Multi Lane Packaging Machine can become a key component for customer's packaging line. Liquid and Viscous High Speed Multi Lane Packaging Machine can produce 30-50 pcs/min/lane depending on the product's volume, size and number of lanes. It can work up to 2-8 lanes.

Liquid and Viscous High Speed Multi Lane Packaging Machine

- Packing lanes: 2-8 lanes

- Working capacity: 30-50 bags/min/lane

Granule High Speed Multi Lane Packaging Machine

Granule High Speed Multi Lane Packaging Machine is mainly used for packaging granule. Elegant sachets could be produced by this high speed packaging machine by hot sealing with rollers and 4 side sealing. With high packaging efficiency, application and multi-lane handling, the Granule High Speed Multi Lane Packaging Machine can realzie high speed packaging for your production line. Granule High Speed Multi Lane Packaging Machine can produce 30-50 bags/min/lane depending on the product's volume, size and number of lanes. It can work up to 2-8 lanes.

Granule High Speed Multi Lane Packaging Machine

- Packing lanes: 2-8 lanes

- Working capacity: 30-50 bags/min/lane