- Home

- Processing and Preparation

- Moulding Equipment

Moulding Equipment

Molding (American English) or moulding (British) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix.

Type 8 Meat & Bacon Press

Type 8-35 presses bellies by means of a die set, in shapes that correspond to the desired finished product. The frozen meat is molded in the hydraulically operated press, where it is exposed to three-dimensional pressure to attain uniform shape and quality for maximized slicing yields. The 8-35 bacon press offers automatic infeed and discharge options with various ancillary systems available. Maximize slicing yields at optimal temperatures ranging from 14°-25° F (-10° to -4° C) depending on salt content.

Type 8 Meat & Bacon Press

- Presses 8 bellies per minute with powerful but gentle hydraulic pressing system

- Press cycle establishes product height and width. Pressed length depends on size of belly.

- Max die chamber size: 35” x 16” x 4.8” (875 x 415 x 120 mm)

- Automatic programmable lubrication system

- Allen-Bradley controls with color touch screen HMI

- Left or right outfeed available

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Type 14 Bacon Press

Type 14 presses bellies by means of a die set, in shapes that correspond to the desired finished product. The frozen meat is molded in the in the servo operated press, where it is exposed to three-dimensional pressure to attain uniform shape and quality for maximiz ed slicing yields. The pressing method ensures that no membranes are damaged, resulting in extra slices. The pressed length is attained with pressure applied from both ends simultaneously. The Type 14 bacon press includes automatic infeed and discharge with additional ancillary systems available.

Type 14 Bacon Press

- Maximize slicing yields at optimal temperatures ranging from 14°-25° F (-10° to -4° C) depending on salt content.

- Presses 14 bellies per minute with powerful but gentle hydraulic pressing system.

- Press cycle establishes product height and width. Pressed length depends on size of belly.

- Max die chamber size: 35” x 16” x 4.8” (890 x 406 x 122 mm)

- Computer controlled die set allows adjusting product thickness ±0.22” (5.5 mm) during operation without changing the die set.

- Automatic programmable lubrication system.

- Internet connectivity option for remote troubleshooting.

- Allen-Bradley controls with color touch screen HMI.

- Left or right outfeed available

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Type 14 Servo Flex Press

Type 14S Servo Flex Press is designed for fully automated operation with a convenient, ergonomic 10" touch screen PanelView interface. The compact, all stainless unit has servos located outside the frame for easy maintenance accessibility. Since the press has no hydraulics, there is no water cooling required, which reduces operating costs and sanitation concerns. The Flex Press can handle 12-16 bellies per minute. Maximum die chamber size is 40 x 16 x 4.7" (1016 x 406 mm x 120 mm), with a height variation up to0.75" (19 mm). The unit presses frozen meat from 4 directions to maximize yield. Pressed product yields a higher percentage of #1 slices when the frozen meat is sliced. Feed conveyors load and discharge frozen bellies, with custom lengths available to integrate with existing production lines.

Type 14 Servo Flex Press

- Flexible chamber to press variable raw material thicknesses and prevent damaged product.

- Extra large press chamber of 40" (1016 mm) presses even the largest bellies

- Remote electrical box away from production floor to protect from moisture.

- 10" PanelView touch screen controls with visual troubleshooting assistance.

- Change diesets in 5 minute without tools.

- Remote online troubleshooting assistance

- Automated flexible slice height up to 20 mm

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Servo Bacon Press

Servo Bacon Press presses bellies by means of a die set, in shapes that correspond to the desired finished product. The frozen meat is molded in the servo controlled press, where it is exposed to three-dimensional pressure from four directions to attain uniform shape and quality for maximized slicing yields. The pressed length is attained with pressure applied from both ends simultaneously. The pressing method ensures that no membranes are damaged, resulting in extra slices. The Type 16 has a 40" (1 m) chamber, the largest in the industry. It also includes automatic infeed and discharge with additional ancillary systems available.

Servo Bacon Press

- Maximize slicing yields at optimal temperatures ranging from 14°-25° F (-10° to -4° C) depending on salt content.

- Servo actuators throughout. No hydraulics for maximized speed and precision control. Smooth operation from optimized motion control prolongs part life and reduces maintenance costs. No hydraulic cooling water needed.

- Presses up to 20 bellies per minute depending on size, the consistency of belly conditions and uniform loading of the infeed belt.

- Computer controlled die set allowing ±0.22” (5.5 mm) adjustment for product thickness during operation without physically changing the die set.

- Press cycle establishes product height and width. Pressed length depends on size of belly.

- Max die chamber size: 40” x 16” x 4.8” (1016 x 406 x 122 mm).

- Change die sets in 5 minutes without any tools.

- Allen-Bradley controls with 12" color touch screen HMI. Intuitive program with extensive diagnostics. Internet connectivity for remote troubleshooting. Remotely mounted electrical panel out of production area.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

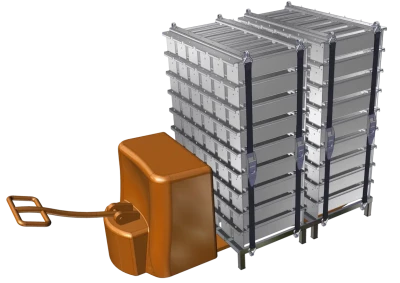

Kit Multimolds

The patented Multimolds kits are design to shape meat products for customers using other cooking and chilling technologies than the Thermix system. The Multimolds kits are used in different applications in the food processing industry.

Kit Multimolds

- The patented Multimolds kits are a 100% stainless steel custom design molds that guarantees total flexibility in products shapes.

- Optimum product shape consistency with accurate dimensions thanks to constant positive interlocks

- Uniform cooking thanks to specifically designed channels for the circulation of the heat transfer fluids

- Optimum hygienic conditions thanks to its sanitary design

- Custom made Multimolds to suit each customer’s need

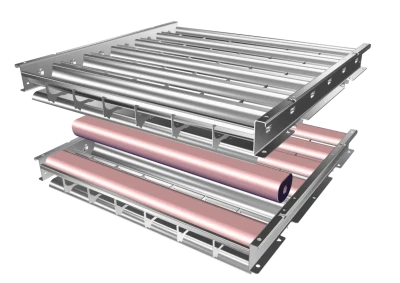

Multimolds for Shaped Ham Logs

Complementary to the Thermix, Multimolds enable molding and handling of products in the Thermix system throughout the whole process. Thanks to their specific shape for each different products, Multimolds enable versatility and are suitable for all kind of products. The patented Multimolds system is very compact and guarantees consistency of the products shape and dimensions as well as a precise homogenous cooking. Multimolds can also be used in some traditional cooking and chilling equipment. 100% stainless steel, Multimolds™ are robust, easy to maintain and easy to clean.

Multimolds for Shaped Ham Logs

- Optimized loading capacity improved by 20 to 30% regards to traditional systems.

- Compatible with automated solutions to load & unload the products.

- Versatile in the product dimensions between logs or delis/loafs.

- Perfectly constant pressing on products resulting in homogeneous products.

- Constant homogenity of slices guaranted no more than +/- 2 mm.