Sheep Processing Equipment

Sheep meat prepared for food is known as either mutton or lamb, and approximately 540 million sheep are slaughtered each year for meat worldwide. "Mutton" is derived from the Old French moton, which was the word for sheep used by the Anglo-Norman rulers of much of the British Isles in the Middle Ages.

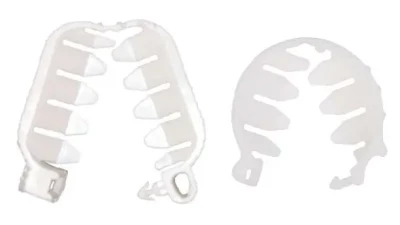

Weasand Clips

for sealing the esophagus of slaughtered stock.

Weasand Clips

- Weasand clips are designed for sealing the esophagus of slaughtered beef and sheep.

- Made of plastic in the U.S.A.

- Designed to keep the esophagus sealed tightly during processing procedures.

- Shipped in clear plastic bags for optimum hygiene and convenience.

- Beef: Available in white, blue and black

- Also available: Rodder for beef and Rodder for sheep

Non Penetrating Pneumatic Stunner

USSS-2 & 2A- pneumatically operated high speed, non- penetrating stunner for cattle and veal.

Non Penetrating Pneumatic Stunner

- Unique design renders the stunned animal insensible to pain, without penetrating the skull.

- One shot humane stunning procedure. Fires only once – no multiple firing needed.

- Better stunning for improved meat quality.

- Two hand control for safer operation.

- Easy to handle and safe to operate – no recoil or kick back – less operator fatigue.

- Easy to repair and clean.

- Lightweight – tool only weighs 36 pounds(16.3 kg).

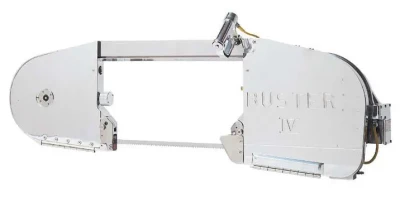

Buster IV Carcass Splitting Bandsaw

Buster IV electrically powered bandsaw for splitting cattle, pigs and sows.

Buster IV Carcass Splitting Bandsaw

- Used in all major U.S. plants for splitting fat cattle (800 – 1050 lbs / 360 – 480 kg).

- Smaller and better handling for optimum performance in the most demanding applications (up to 180 beef / hour / saw).

- Superior blade life: 400 – 600 carcasses per blade.

- Best possible hygiene – spoked wheels, flat surfaced housings and completely opening doors – for fast, easy and complete cleaning.

- The drive system is oil bath lubricated for sustained trouble-free operation.

- Designed for the operator – ultra-thin rail for unobstructed vision and dual rear handles for comfort.

- Anti-tie down controls and totally enclosed electric motor for operator safety.

- Meets national and international requirements for hygiene and safety.