- Home

- Slicing Loading and Packaging

- Aligning Equipment

Aligning Equipment

Aligning is important when it comes to loading industrial manufactured goods. This technique is usually applied to natural casing sausages; skinless, soft sausages; chubs; and salamis manufacturing industries.

CS 900 Corn Dog Loader

CS-900 integrates into a corn dog batter/frying line. The unit automatically feeds cooked and peeled sausages onto a continuous moving flighted conveyor belt. At this point, product is presented to the auto-skewer section of the corn dog fryer. Skinless, cooked and chilled frankfurters from 16 to 32mm in diameter are within the acceptable standards. This Loader aligns product on the fryer conveyor at up to 26 hot dogs per index, resulting in the processing of 16,000 pieces/hour. Thus, meeting the fryer’s speed and product supply requirements. An elevating supply conveyor may be added to this system to feed product into the CS-900.

CS 900 Corn Dog Loader

- You thought there was a placeholder text here, but it was me DIO!

The ProStax DS 6 & 13 Drop Stacker

The ProStax DS Drop Stacker is designed to interface with our 100 Series ProLeavers. Its compact design means it can fit into almost any food production operation and its pneumatic motion control means it’s easy and affordable to maintain. The DS counter/stacker is equipped with an exit conveyor that is configurable in the field for inline discharge or discharge at 90 degrees for a more compact layout. Widths of 6” and 13” and cycle rates up to 100 per minute allow this compact system to produce at a very high level. It is great for automatic food stacking with cheese, pizza crust, flatbreads, raw dough, pressed cheese flats, omelets, deli meats etcetera. It can also be used as a burger stacking machine to load fresh burgers directly into a tray.

The ProStax DS 6 & 13 Drop Stacker

- You thought there was a placeholder text here, but it was me DIO!

The ProStax PS 13 Platform Stacker

The ProStax PS Platform Stacker for our 100 Series ProLeaver is available in 13” width and is designed for short portions, 6” and under in one or two lanes. While all ProStax automatic stacking systems eliminate labor and repetitive motion, the ProStax PS is designed to reduce the drop height of portions when counting and stacking. It’s great for deli meat and cheese.

The ProStax PS 13 Platform Stacker

- You thought there was a placeholder text here, but it was me DIO!

ProStax USS Universal Shuttle Stacker

The ProStax USS is the most flexible automated food stacker in the ProStax line-up. While many stackers are focused on long or short portions to achieve maximum speeds, the Universal Shuttle Stacker is built to handle both long and short portions with no changeover. In keeping with its “universal” name the USS is also great for applications that need to run without paper or “bypass” the ProLeaver. By simply turning the ProLeaver and the ProStax into bypass mode, products can be sent over the system without moving line components or adding auxiliary conveyors. Many other ProStax models require paper under portions to perform optimally. ProStax USS can stack products with or without paper.

ProStax USS Universal Shuttle Stacker

- You thought there was a placeholder text here, but it was me DIO!

ProStax CBS4 Cooked Bacon Stacker

ProStax CBS4 is the world’s only counting and stacking automation solution for pre-cooked bacon. Built specifically to automate the traditionally manual process of counting and stacking sheets of cooked bacon, the system overcomes the challenges related to conveying and stacking bacon of different cook levels. As an example, the stacker handles thin dry bacon just as well as greasy thick bacon. This is truly a breakthrough. In addition to reducing labor and repetitive motion injuries, the system combines the finished stacks into a single lane of flow for easy conveying to a packaging machine. The ProStax CBS can be optioned in a 2, 3 or 4 lane configuration to suit virtually any cook line. The system consists of a “module on frame” design meaning the stacker can be configured with either 2, 3 or 4 stacking modules attached to a common frame. These automated food stacking modules can be easily removed and maintained or repaired off-line in the maintenance shop.

ProStax CBS4 Cooked Bacon Stacker

- You thought there was a placeholder text here, but it was me DIO!

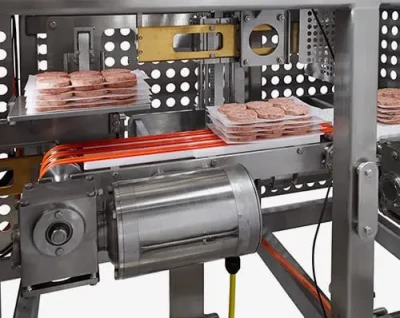

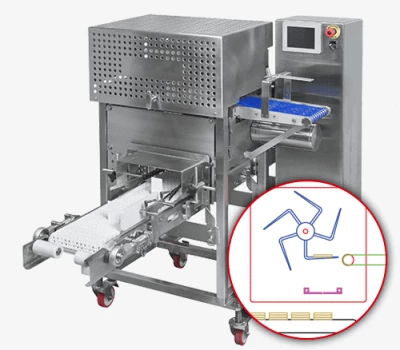

ProStax HPS Homestyle Patty Stacker

The ProStax HPS is specifically designed to count and stack fresh, formed, homestyle hamburger patties that have been interleaved on one of our ProLeaver systems. What really sets the ProStax HPS apart is its ability to drop stacks of burgers directly into trays. Further, at speeds up to 230 patties per minute this high speed stacker outpaces any competing solutions.

ProStax HPS Homestyle Patty Stacker

- You thought there was a placeholder text here, but it was me DIO!