- Home

- Slicing Loading and Packaging

- Loading Equipment

Loading Equipment

Loading and unloading can be the most critical and complex point in a temperature controlled supply chain. Transferring product from one location to another adds factors to the process that are often unmonitored. Fortunately technology is rapidly improving in this critical space. In addition to maintaining the temperature of the truck, warehouse, and product, shippers and carriers must also take into consideration the temperature of the loading dock, outdoor weather conditions, and even the time it takes to load and unload items. While the shipper and carrier should each have specific obligations to fulfill during this process, confirming the work of the other party can help minimize problems and identify areas for improvement.

Pallet elevators and descenders

These automated pallet handling systems are a fundamental component of industrial automation and represent a strategic choice for a large number of sectors and production areas. One of the key aspects that distinguishes their potential is the wide flexibility in terms of implementation and customization. It is possible to complete each elevator and descender for pallets with a variety of equipment pieces and accessories, such as roller or chain conveyors, loading or storage bays at desired height, and any other automation and palletized goods handling devices required. Thanks to the consolidated experience in the sector, we consider ourselves as ideal partners for every need in the field of industrial automation . The elevators and descenders for pallets made and installed by us are the result of a tailor-made design , starting from the specifications of each individual customer. Whether it is the construction of new turnkey systems or the supply of individual pieces of equipment for automated logistics already in operation, we have the most suitable solution for every need. The quality of each item is guaranteed by the tests that are conducted before delivery by our specialist personnel. While to guarantee maximum reliability, our assistance service is always available for any after-sales intervention. Used to transfer goods vertically between floors at different heights, the pallet elevators are widely used in situations of interlocking buildings and shelves on multiple levels. Our solutions are able to move multiple pallets simultaneously for each operating cycle, transiting tracks of up to 35 meters . Available in indoor or outdoor execution and with various access configurations, the elevators we make are suitable to be easily integrated into both new and existing structures. Thanks to the robust, fully self-supporting metal structure, our elevators do not require the construction of runways or reinforced concrete structures. Furthermore, depending on the number of drives, the track and the speed, the lifting system can be hydraulically operated, with direct or indirect side cylinder, or electromechanically, with chain and counterweight transmission system.

Pallet elevators and descenders

- Tracks up to 35 meters

- Suitable to be easily integrated into both new and existing structures.

- Customised design

- The pallet elevators can be created in a semi-automatic version with manual loading and unloading or in an automatic version, combined with systems for translating the load with chains or motorised rollers.

Diverters for loaded and empty pallets

The corner diverters for pallets are made with a roller and chain system ; they are used to make 90 ° movements on roller conveyors and to move the load between one roller conveyor and another. The diverter for roller and chain pallets consists of a roller conveyor and a chain conveyor, placed at right angles to each other, which allow the pallet’s axis of advancement to be changed by 90°. The chain conveyor, at the junction point with the roller conveyor, tilts with a vertical movement, allowing the palletised load to pass from one conveyor to another.

Diverters for loaded and empty pallets

- Thanks to a modular design, the diverters that we produce are able to satisfy all requirements in terms of size, configuration and speed dictated by the customer.

- The sectors of use include the food and beverage industry, the chemical and pharmaceutical industry and logistics.

- The machines for industrial handling and automatic industrial handling systems are studied and designed by us in order to optimise the work flow, the customer’s production requirements and the structural needs of the building.

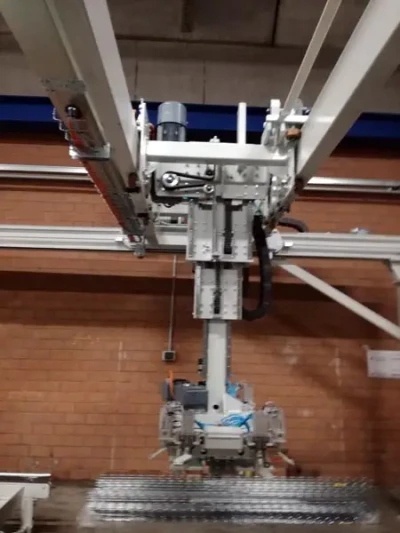

Cartesian telescopic palletisers

The Cartesian telescopic palletiser has been designed for those who, in small spaces, need to make the work of loading, arranging and stacking products on pallets automatic, quick and safe. The system can handle bags, flexible bags, cartons, boxes, drums, bottles and any kind of item that is positioned and aligned on the pallets thanks to the multi-axis system with special customised grippers. The palletisers we have created allow us to optimise business efficiencies, saving time and money as, thanks to these tools, the constant supervision of operators involved in the palletising and storing of goods is unnecessary. An automatic palletiser ensures the supply of all the incoming and outgoing movements of the product to be palletised, management of the positioning of the interlayer, the handling of empty pallets and the transportation of full pallets. The classic modular structure can be extended, according to requirements, to create palletising lines at multiple stations with various picking points being served.

Cartesian telescopic palletisers

- Sturdiness, versatility and ease of use

- The Cartesian palletiser is programmed via PLC and this allows optimisation of the work cycles as required.

- Palletising takes place through the pick & place method, picking up the product individually or not and depositing it on the pallet according to the programmed scheme.

- The vertical telescopic arm allows the use of various types of gripping modules and allows positioning of the packs also in high containers, such as carton-boxes, pallet-boxes and octabins.

- The electronics used allow the creation of any type of layer, while the easy-to-use management software allows even the less experienced operators to quickly change the work program and even to modify the palletising scheme to adapt it to various requirements.

Motorized roller conveyors for handling pallets

The roller conveyors can be cylindrical or conical rollers, idle, motorized or friction-based, with belts, or roller chains. Due to ease of use and reliability, they represent the most suitable and functional solution for handling on a horizontal plane, at low and medium speeds. Boxes, pallets, drums and a whole series of products, which can be remarkably heavy, can be accommodated on a regular support surface. Motorised roller conveyors are types of industrial conveyors that allow the movement of material, components or finished products from one part of the production cycle to another in an automated manner and without the use of personnel. These automatic handling systems, in fact, connect the various industrial machines, transporting the loads autonomously and with absolute precision, for example in the final phase of the cycle when the products are being prepared for shipment. Our conveyor belts are made to measure, according to the specific needs of the customer and in full compliance with safety at work regulations and in accordance with the EC machinery directive. The construction dimensions and all the technical characteristics are discussed with the customer during the estimate phase. The roller conveyors are used in particular in warehouses and storage environments, where the pallets are transported autonomously and mechanised, quickly and with maximum precision. These automated handling systems have become an integral part of the modern industrial and manufacturing process. Whether it is boxes or small and large packs, the conveyor roller conveyors provide a fast, effective and economic service in the handling of material in the production chain.

Motorized roller conveyors for handling pallets

- High modularity and extreme reliability

- Maximum precision and speed

Rotating platforms for pallet diversion

The rotating platform is a solution that is used to divert the pallet thanks to a system that can be roller- or chain-based. This system allows the load to move in any direction with respect to that of entry, with rapidity and flexibility, in order to optimise spaces and to follow the best handling route.

Rotating platforms for pallet diversion

- You thought there was a placeholder text here, but it was me DIO!

Empty pallet warehouse

The empty pallet warehouse is a device that allows the automatic feeding of pallets on the line , guaranteeing system autonomy. The vertical movement is motorised and the pallet stacks are gripped with pneumatic movement. The empty pallet storage device responds to the need to deposit empty pallets on one side and supply the production line on the other. The operator deposits the empty pallets in the warehouse and the automatic device equipped with its conveyor will dispense the pallet on the line to receive the product.

Empty pallet warehouse

- Reliable and state-of-the-art handling systems

- Systems that do not require maintenance: The feed mechanism has no parts that require lubrication, thus eliminating any type of maintenance. In addition, there are sensors that indicate the presence of the pallet and when the warehouse is low.