Sterilization Equipment

Sterile dosage forms must be isotonic and free from dust, foreign particles, and microorganisms. Sterilization refers to any process that removes, kills, or deactivates all forms of life (in particular referring to microorganisms such as fungi, bacteria, spores, unicellular eukaryotic organisms such as Plasmodium, etc.). After sterilization, an object is referred to as being sterile or aseptic.

Automatic IV Solution Sterilization

Automatic IV Solution Sterilization includes automatic conveying, loading and unloading of IV solution products. Can also integrate loading / unloading cart system which compliments greatly to pharmaceutical automation. Automatic IV Solution Sterilization equipment does not only boost integral image of your prduction line but also reduce labor intensity and gurantee quality of IV solution produced.

Automatic IV Solution Sterilization

- It uses four-axis robots to automatically place bags into sterilization trays and has a cage-shaped automatic bag unloading machine. Belt conveyors and a 90-degree turn belt conveyors are used to conveying bags. The whole system runs stably and reliably

- Bag detection station can be added to prevent mixed batch and improve production quality

- The system uses modular design and can be specially designed according to user site

- It is suitable for various specification products, and has the function of recipe storage and use. The operation is easy and simple

- Empty trolley station can be Human-Centered Designed according to user requirements and user site under the condition of meeting production requirements

Wash Sterilize Fill Seal Line

Vial Wash-Dry-Fill-Seal Production Line is used the washing, sterilization, filling and sealing of small volume vial injection in workshop. It features advanced design, reasonable structure, high degree of automation, stable and reliable operation, high production efficiency and mechanical and electrical integration. The parts contacted with drug liquid are made of AISI316L and the other are made of AISI304. The materials used have no pollution on drug and environment.

Wash Sterilize Fill Seal Line

- Vial specification: 1ml-100ml

- Output capacity: 10-500 vials / minute

- Filling accuracy: ≤±1%

- Ultrasonic washing + Water-Air alternating washing

- Brands of core components: SIEMENS, GEMU, FESTO, ABB, Schneider, etc.

- The overall design and manufacturing are in line with FDA and the new GMP.

- Vial Wash-Dry-Fill-Seal Production Line is composed of Vertical Ultrasonic Washing Machine, Drying and Sterilization Oven, and Vial Fill-Seal Machine. It features coordination interaction, stepless speed regulation and accurate control and can meet production process requirements.

- It features high production speed, high qualification rate, no impact, no wrong action, no squeezing and on broken vials.

- It is equipped with various safety devices to ensure the safety of the operator and machine.

- Validation ports are reserved on main parts.

- It features PLC control, touch screen operation and programmed production.

- Buffer devices are installed on the connection point between three units of the production line, thus able to ensure reliable and stable operation.

- It has the function of no bottle no filling.

- It has centralized oil supply system which can easily add oil on lubrication points.

Super Heated Water Sterilizer

Super Heated Water Sterilizer is a high-performance and high-intelligence large infusion sterilization equipment, which is mainly used for the sterilization of plastic IV bottle or bags. High-temperature superheated water is used as heating media. The heat energy carried by the superheated water is transferred to the products, thus ensuring the uniformity of the sterilization temperature. High-temperature circulating water is used as sterilization media. The unique pressure balancing technology used in the sterilization process ensures that plastic bottles or bags will remain in good shape after sterilization.

Super Heated Water Sterilizer

- You thought there was a placeholder text here, but it was me DIO!

Dry Heat Sterilizer

Dry Heat Sterilizer is mainly used for sterilization of high temperature resistant materials. It uses circulating hot air as working media for sterilization and depyrogenation and meets GMP and FDA requirements. Put articles into chamber, start sterilization cycle, then circulating fan, heating pipes and air valves will work together for rapid heating. With the help of circulation fan, the dry hot air flows into chamber by way of high temperature resistant HEPA and forms uniform air flow. The moisture on the surface of the articles is taken away by dry hot air and then is discharged out of chamber. When chamber temperature reaches a certain value, the exhaust valve is closed. The dry hot air circulates in the chamber. With the intermittent fresh air intake, the chamber has positive pressure. After sterilization phase is ended, fresh air or cooling water inlet valve is open for cooling. When temperature drops to the set value, automatic valves close, and an audible and visual alarm is given for indication of opening door.

Dry Heat Sterilizer

- You thought there was a placeholder text here, but it was me DIO!

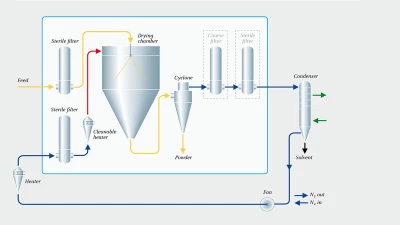

Aseptic Spray Dryer

For decades, spray drying has been applied for powder production by the pharmaceutical industry – also under aseptic conditions. The Aseptic Spray Dryer is perfect for the production of sterile pharmaceutical products such as vaccines, antibiotics and other products requiring aseptic conditions. A precise control of the drying process gives far greater command over the shape, density and morphology of the final product than other aseptic drying technology, and moreover, with low running and capital costs, these advantages are obtained while reducing overheads. Production of dry sterile dosage forms often involves mixing of the API with one or more excipients. To achieve a homogeneous mixture, the particle size distribution of the excipient(s) must match that of the API. In a one-step-operation, aseptic spray drying can turn a sterile solution into sterile particles of the required size with no risk of introducing impurities. The spray dryers are also designed for handling organic solvents, which makes possible the use of a wide range of excipients within the formulation.

Aseptic Spray Dryer

- You thought there was a placeholder text here, but it was me DIO!