- Home

- Thermal Processing

- Automated Cooking Equipment

Automated Cooking Equipment

Advanced cooking techniques most of the time require specific steps. An automated cooking line makes the steps involved in cooking food faster, easier and accurate which minimizes human error during production.

Thermix Sous Vide

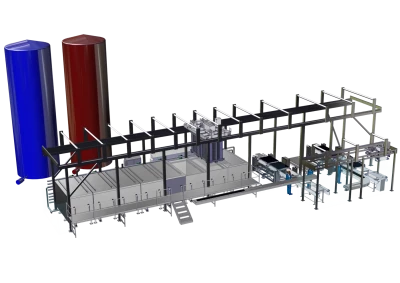

Thermix Sous Vide System is a fully automated, advanced water cook & chill process especially design for Sous Vide cooking technology. Industrial food processors can consistently produce guaranteed safe food product of the best quality at highest yields. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope.

Thermix Sous Vide

- Thermix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Thermix to suit customer's need

- The automated Thermix Sous Vide System works continuously at a steady pace of 0.5 to 5 tons per hour with various levels of automation delivering a constant flow of superior-quality products with minimal human labor involvement. The system streamlined design results in exceptionally low maintenance costs

Thermix for Hams

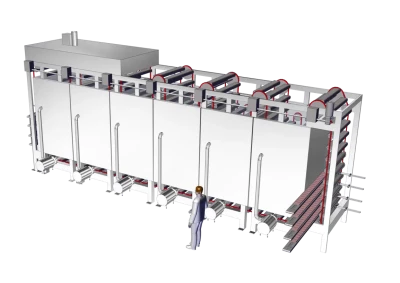

The Thermix Ham system is a fully integrated solution to automatically shape, cook, chill and transfer cooked meats within the processing system. With the fully automated Thermix Ham system, processors can produce from 20 to 200 metric tons per day with as little as 2 employees having the lowest manufacturing costs in the industry.

Thermix for Hams

- The Thermix system is a patented modular cooking and chilling process by immersion with continuous circulation of water and recycling of hot, cold and chilled fluids. The Thermix system significantly improves process control and product consistency while dramatically reducing labor cost and enery consumption.

- Molding The patented highly compact Multimolds technology shapes and molds product with consistent accurate dimensions for optimum product shapes, providing superior finished products with the highest slicing yields.

- Cook, Cool and Chill: The Thermix allows total control of the product cook, cool and chill process cycles for consistent repeated results, ensuring the highest cooking yields.

- Freezing: With our negative cold solution, your products can be frozen directly in Thermix in an optimal way while ensuring complete traceability of the cooking, chilling and freezing process.

- Product handling: The Logi-Flex automated system provides a large variety of handling solutions, from loading the products to the Multimolds to unloading the finished products to slicers, racks or pallets.

- The Thermix Ham system combines high output with production flexibility, optimum production performances with high productivity, low operations costs with large energy savings and food safety with complete traceability.

Pico Thermix

The Pico-Thermix is by far the smallest unit that we developed with our industrial customers to perform R&D tests with the same level of expertise that the Thermix solution provides. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope. Sous Vide offers the longest shelf life for natural and tasty products without preservatives, resulting in benefits for all users. The Pico-Thermix system flexible, unique design and controls allows processing a variety of products. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

Pico Thermix

- Undisputed quality

- Food safety & traceability

- Integrated heating & chilling

- Best consistency & clean label

- Batches of 4-6kg | 11lbs

- Advanced recipe controls

- Complete traceability plotting

- Remote web-based monitoring Thermix™ Connect

- Suited for 220/50Hz and 220V/60Hz

- No plant utility required. Works perfect at home.

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

Vacuum Oil Fryer

With Vacuum Frying Machine's efficient and fully automatic control module you can produce high quality fried products. You can never go wrong adding this equipment to your production line with its wide range of applications! Applicable products include but not limited to fruit and vegetables chips, small crispy fish and other products with low oil content.

Vacuum Oil Fryer

- Stable

- Simple operation

- Efficient process and energy saving

- Wide range of applications