- Home

- Thermal Processing

- Chilling Equipment

Chilling Equipment

Cooling is used to reduce the temperature of the food from one processing temperature to another or to a required storage temperature. Chilling is a processing technique in which the temperature of a food is reduced and kept in a temperature between -1 to 8°C.

Jelly Tank Gelix

The patented Gelix system has been designed to optimize jelly preparation, semi-liquid and liquid blends with the highest quality standard for the food processing industry. Thanks to its technology the Gelix system is used in multi-industry applications: Jelly preparations, Fat melting, Marinades and sauces and/or Bakery filling preparations.

Jelly Tank Gelix

- The Gelix is an integrated system, that is compose of a temperature regulated agitation tank and a depositor

- Instant blend preparation

- Cook & chill

- Optimum product distribution

- Product pasteurization

Kitchenix

The Kitchenix is a fully automated advanced water cook & chill system for Sous Vide cooking technology. It has been specially designed to meet small and medium production needs like Restaurants, Ghost and satellite kitchens and Caterers.

Kitchenix

- The Kitchenix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Kitchenix to suit customer's need

- The Kitchenix system includes Thermix Connect web based controls and mobile app which allow users to monitor overnight cooking without having physical presence on the kitchen.

Thermix Sous Vide

Thermix Sous Vide System is a fully automated, advanced water cook & chill process especially design for Sous Vide cooking technology. Industrial food processors can consistently produce guaranteed safe food product of the best quality at highest yields. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope.

Thermix Sous Vide

- Thermix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Thermix to suit customer's need

- The automated Thermix Sous Vide System works continuously at a steady pace of 0.5 to 5 tons per hour with various levels of automation delivering a constant flow of superior-quality products with minimal human labor involvement. The system streamlined design results in exceptionally low maintenance costs

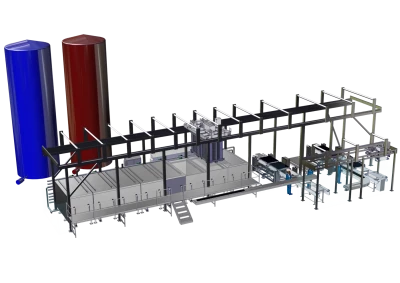

Thermix for Hams

The Thermix Ham system is a fully integrated solution to automatically shape, cook, chill and transfer cooked meats within the processing system. With the fully automated Thermix Ham system, processors can produce from 20 to 200 metric tons per day with as little as 2 employees having the lowest manufacturing costs in the industry.

Thermix for Hams

- The Thermix system is a patented modular cooking and chilling process by immersion with continuous circulation of water and recycling of hot, cold and chilled fluids. The Thermix system significantly improves process control and product consistency while dramatically reducing labor cost and enery consumption.

- Molding The patented highly compact Multimolds technology shapes and molds product with consistent accurate dimensions for optimum product shapes, providing superior finished products with the highest slicing yields.

- Cook, Cool and Chill: The Thermix allows total control of the product cook, cool and chill process cycles for consistent repeated results, ensuring the highest cooking yields.

- Freezing: With our negative cold solution, your products can be frozen directly in Thermix in an optimal way while ensuring complete traceability of the cooking, chilling and freezing process.

- Product handling: The Logi-Flex automated system provides a large variety of handling solutions, from loading the products to the Multimolds to unloading the finished products to slicers, racks or pallets.

- The Thermix Ham system combines high output with production flexibility, optimum production performances with high productivity, low operations costs with large energy savings and food safety with complete traceability.

Pico Thermix

The Pico-Thermix is by far the smallest unit that we developed with our industrial customers to perform R&D tests with the same level of expertise that the Thermix solution provides. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope. Sous Vide offers the longest shelf life for natural and tasty products without preservatives, resulting in benefits for all users. The Pico-Thermix system flexible, unique design and controls allows processing a variety of products. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

Pico Thermix

- Undisputed quality

- Food safety & traceability

- Integrated heating & chilling

- Best consistency & clean label

- Batches of 4-6kg | 11lbs

- Advanced recipe controls

- Complete traceability plotting

- Remote web-based monitoring Thermix™ Connect

- Suited for 220/50Hz and 220V/60Hz

- No plant utility required. Works perfect at home.

Industrial thawing systems ATA

The optimal system for balanced thawing without much weight loss. This thawing system has the best prerequisites for consistent quality in the subsequent processes.

Industrial thawing systems ATA

- Consistent thawing with high loading capacity

- Variable: The customer can supply the processing room from insulated panels or insulated brickwork.

- Minimum energy consumption: The system’s energy supply is chosen so that the target values can be rapidly achieved. All thawing processes can be controlled and regulated via the operating temperature, the core temperature or the peripheral temperature.

- Environmentally friendly: Minimum energy consumption: Individual air circulation systems and fresh air / exhaust air controls for each trolley place considerably reduce process times and thus energy requirements. Each trolley place is processed at the same temperature and relative humidity.