- Home

- Industries

- Food

- Bacon

Bacon Equipment

Bacon is a type of salt-cured pork made from various cuts, typically the belly or less fatty parts of the back. It is eaten as a side dish, used as a central ingredient, or as a flavouring or accent (as in bacon crumbles in a salad). Manufacturing bacon usually involves injection followed by a short massaging process and cooking along with smoking and chilling. With RGMTSI bacon manufacturing equipment, factors in each step that require consistency will be achieved resulting to a high-quality product. All of our equipment follows good manufacturing practices as well.

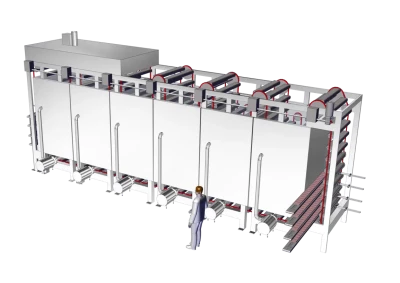

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

ProLeaver 6100

The ProLeaver® 6100 is an economical, flexible, entry-level automatic food interleaver designed to help manufacturers automate small production lines and allow them to become more competitive in today’s markets.

ProLeaver 6100

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

ProLeaver 13100

The ProLeaver® 13100 and ProLeaver® 13100 Twin Lane offer the same speed, accuracy, and value as the narrower ProLeaver® 6100 but with a wider paper path and the ability to cut two lanes of paper.

ProLeaver 13100

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

The ProLeaver 9300

The ProLeaver 9300 Small Form Factor Interleaver Stacker presents a small footprint that saves space over other automated food interleaving systems that are available. The rugged stainless steel design of each automated food machine meets and exceeds industry sanitation standards. The control and drive enclosures are fully gasketed for 100% wash down capability. The ProLeaver 9300 is also designed to easily interface with your packaging machinery. PLC design allows easy production set-up, changes, and networking with other equipment. The ProLeaver 9300 can provide a single bottom sheet or full-wrap interleaving, while achieving high-speed, fully automatic operation. It can also be outfitted with a remote monitoring and diagnostic system (RMDS). Perfect for burgers, deli meat, bacon, tortillas, cookies, and pasta.

The ProLeaver 9300

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

The ProLeaver 20300

The ProLeaver 20300 features up to 200 rows per minute, up to four lanes of paper, the ability to run paper or plastic film and multiple stacking options.

The ProLeaver 20300

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

The ProLeaver 26300

The ProLeaver 26300 is the most compact stand-alone paper feeder in the world. It can be configured to only add 30” in length to your food processing line and still interleave up to 26” wide paper or up to 6 lanes of narrower paper.

The ProLeaver 26300

- Rapid ROI

- Positive brand perception in the marketplace

- Reduced packaging and labor costs

- Increased efficiency and safety

- Reduced labor headaches

- Minimized production handling

- Reduced repetitive motion injuries

- Increased production volume

- Reduced downtime

ProStax CBS4 Cooked Bacon Stacker

ProStax CBS4 is the world’s only counting and stacking automation solution for pre-cooked bacon. Built specifically to automate the traditionally manual process of counting and stacking sheets of cooked bacon, the system overcomes the challenges related to conveying and stacking bacon of different cook levels. As an example, the stacker handles thin dry bacon just as well as greasy thick bacon. This is truly a breakthrough. In addition to reducing labor and repetitive motion injuries, the system combines the finished stacks into a single lane of flow for easy conveying to a packaging machine. The ProStax CBS can be optioned in a 2, 3 or 4 lane configuration to suit virtually any cook line. The system consists of a “module on frame” design meaning the stacker can be configured with either 2, 3 or 4 stacking modules attached to a common frame. These automated food stacking modules can be easily removed and maintained or repaired off-line in the maintenance shop.

ProStax CBS4 Cooked Bacon Stacker

- You thought there was a placeholder text here, but it was me DIO!

PPI 200 SS CD Card Feeder

The PPI-200-SS-CD card feeder is designed specifically for harsh environments and interfaces easily with any slicing, forming, processing, or packaging equipment in your commercial bacon production line. Our inline designs save valuable floor space, while automated reloading systems allow for continuous operation, and precision card placement ensures accurate automation of bacon packaging materials. This reliable feeding system will not jam or double-feed when working with bacon packaging materials, as is common with traditional card feeders. Its large-capacity magazine allows for extended run time (up to 45 minutes between reload), and the system features an automated, UPC code-enabled fast setup to accelerate card setup and changeover. Versatile designs allow users to run many types of cards (e.g. window, non-window, foldable flap, or no flap). The PPI-200-SS-CD feeds up to 80 cards/minute and is guaranteed to reduce downtime associated with bacon packaging materials, such as missed cards, double feeds, and jams.

PPI 200 SS CD Card Feeder

- You thought there was a placeholder text here, but it was me DIO!

IBS 1000 Bacon Slicer

The IBS 1000 Bacon Slicer offers high quality retail and wholesale back, belly and middle bacon slicing for manual packing operations in a compact footprint. The slicer was developed based on proven technology to suit small and medium sized processors who are looking to improve slice quality while increasing throughput and yields.

IBS 1000 Bacon Slicer

- High speed bacon blade of up to 1600rpm for consistent slice thickness and integrity

- Small, space saving footprint

- Fast reload of <6 seconds

- Gripper fed for minimum butt ends (80-100g typical)

- Yield improvement of 1.5 to 2%

- Hygienic, stainless steel construction to ‘ready to eat’ product standards; CE marked

- Simple to operate and maintain

- Optional Underleaver for layout and platter food service drafts

- Adjusts the thickness of each slice to significantly improve first time on-weights, reducing rework rates and giveaway

- Slicer on-weight percentages in excess of 90%

- Anticipated giveaway of 1% or less for on-weight packs

- For best performance, a process weigher is recommended to provide weight feedback

- Enhanced on-weight performance reduces rework

- Reduction of EOL giveaway by up to 3.5%

- Includes a predictive weighcell positioned adjacent to the slicer on a mobile stand

- For best performance, a process weigher is recommended to provide weight feedback

T1 Bacon Slicer

The T1 bacon slicer is a dedicated high performance slicer for turkey and belly bacon applications and provides unprecedented yield and throughput to retail and food service bacon producers. This dedicated bacon slicer produces consistent slices day in and day out, without thick-thin slices or slivers, while providing great first time on-weight performance and low giveaway for drafts of fixed weight and slice count.

T1 Bacon Slicer

- Produces in excess of 100 retail drafts per minute

- Produces up to 140 10-slice food service sheets per minute

- Top-spec cut face vision system with fat & lean detection enables slicer on-weight percentages up to 95% as well as grading functions

- Giveaway of less than 1% for on-weight packs

- Accurate, continuous feed with compact autoloader maximises throughput

- Selection of discharge options enables optimization of retail and food service drafts

- Debris conveyor delivers trim and end pieces outside of the machine guarding

- Remote Electrical Cabinet

- Use of optional Loading Module enables buffering of up to 12 bellies