- Home

- Industries

- Food

- Ham

Ham Equipment

Ham is pork from a leg cut that has been preserved by wet or dry curing, with or without smoking. As a processed meat, the term "ham" includes both whole cuts of meat and ones that have been mechanically formed. RGMTSI's ham process equipment can reduce your massaging time by 50% or more and reduce or completely eliminate curing hold-time to facilitate continuous production with program- driven massaging cycles.

PrimeMove Inclined Screw Loader

Screw Loaders (CSL) are ideal for storing and transferring products from dumpers, mixers, conveyors and other sources. The heavy-duty inclined screw loader utilizes a feedscrew that discharges directly onto various ancillary systems.

PrimeMove Inclined Screw Loader

- Unique, quick-release, watertight shaft seals for full washdown sanitation.

- Heavy duty, stainless feedscrew auger is available in diameters from 9" (230 mm) to 20" (500 mm).

- Wide range of hopper sizes, discharge angles and heights custom-made to your requirements.

- CSL units available in capacities ranging from 2000 lbs. to 8000 lbs. (900 kg-3600 kg).

- Optional agitator is available to prevent bridging of product.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

Stuffing Hoppers (CSH) are designed to integrate seamlessly into today's high volume, continuous processing lines. Direct-discharge valving systems enable CSH units to automatically receive product from upstream units. This greatly reduces or in many cases, completely eliminates human labor associated with handling and transporting of product, thus eliminating product contamination. The modular CSH system can be custom configured from one to multiple chamber units and can be equipped with numerous options to maximize the efficiency of your specific operation. Our CSH units are especially useful when incorporated into a complete emulsion/reduction line.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

- Each hopper utilizes an independent hydraulically driven, stainless steel, positive displacement (PD) pump.

- Bypass valves are completely eliminated and steady line pressures of 70-80 psi (4.8-5.5 bars) are maintained for exact finished product weight.

- Custom designed hoppers to fit your production requirements and floor plan.

- Quick-release coupling device between hopper throat and PD pump and easily accessible pump rotors for thorough sanitation.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Transfer Hopper with Stainless PD Pump

The custom designed Transfer Hopper with PD Pump fits cleanly under a mixer / blender in a emulsion line. Designed to transfer to a storage silo or other large vessel, the transfer hopper easily spans the width of the mixer discharge area to eliminate product spillage. The powerful positive displacement pump eliminates the need to elevate the upstream equipment to fully empty a mixer. Pump silos can store enough blended material to continuously feed the emulsion system. When used downstream of the emulsifier, the transfer hopper can provide a continuous feed into stuffers or linkers.

PrimeMove Transfer Hopper with Stainless PD Pump

- Capacities to fit your application with sizes up to 20,000 lbs. (9,100 kg)

- Transfer rates up to 1,000 lbs/minute (450 kg/min.) using our PD650 pump

- Eliminates the need to elevate the upstream equipment to fully empty a mixer

- Available with our 500, 575 or 650 PD pumps depending on the application

- Electric or hydraulic powered pump

- Pivoting pump base for easy sanitation

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design

PrimeMove VSS-3 Vacuum Stuffing / Filling System

When it comes to high volume, continuous-flow, vacuum stuffing and filling applications, the Vacuum Stuffer (VSS) series stands in a performance class by itself. With the unique VSS design, improved / consistent finished product vacuum levels and high volume flow rates are ensured. The VSS utilizes dependable hydraulic power. A fully integrated heat exchanger keeps hydraulic fluid cool for dependable operation even under extended periods of heavy usage. From fine emulsions and coarse reductions, to sectioned, whole muscle mixtures, VSS brings a new level of efficiency and economy to any high volume stuffing / filling system.

PrimeMove VSS-3 Vacuum Stuffing / Filling System

- Vacuum stuffing capacity: Up to 28,000 lbs. (12,700 kg) per hour, depending on product.

- Variable speed vane pump, feedscrew and agitator are powered by a heavy-duty hydraulic drive system.

- Vacuum cover opens and closes pneumatically. For operator safety, an interlock device prevents the lid from accidental closure.

- Quick and easy vacuum loading.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

SUSPENTEC Particle Reduction System for Injection Processes

Used worldwide to process roast beef, ham, turkey breast, chicken products, steaks, fish, bacon and various other whole-muscle products, the patented SUSPENTEC process has brought significant profit building advantages to users everywhere. Hundreds of processors of fresh, cooked, refrigerated or frozen meats and seafood worldwide are using the SUSPENTEC system to add value to their products while lowering their costs of finished goods. An application-customized SUSPENTEC system inject lower cost protein materials into higher cost whole muscle products. Enhanced binding, reduced cook and chill shrink and increased slicing yields are just a few benefits realized. The heart of the SUSPENTEC process lies in its high-throughput, precise, MultiCut reduction system where the mixture recirculates through the reduction unit and mixing hopper until it becomes a homogeneous mixture of brine and ultra fine particles of meat. When exact particle size or temperature is achieved, a divert valve automatically directs suspension to feed one or two holding hoppers. An optional chiller maintains the critical suspension temperature. From the holding hopper(s), a pump delivers suspension to a standard injector. Whole muscle product is then injected with the suspension to the preset yield gain. Excess suspension from the injector is captured by a return hopper and reprocessed. The modular and compact SUSPENTEC system is adaptable to practically any plant layout.

SUSPENTEC Particle Reduction System for Injection Processes

- SUSPENTEC system consists of Mixing hopper with MultiCut reduction unit, Holding hopper(s) with optional chiller(s), Return hopper from injector, Return reduction unit (optional).

- The process involves mixing a brine solution with lower cost materials such as trimmings, rework, etc. and injecting mix into more costly whole muscle product.

- The modular SUSPENTEC system is adaptable to each unique application depending on plant layout and space considerations.

- Increased bind, reduced cook and chill shrink, increased slice yield and lower overall product cost.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Declipper

Automate the process of removing wire clips on the ends of chubs with the Declipper. Safeguard your ready-to-eat products from the risk of contamination by eliminating inefficient manual declipping with this productivity-boosting machine. Feeding directly from a Chub Separator or manually, the infeed conveyor indexes the product to the declipping head stations and then stops. The declipping heads simultaneously approach the product from both sides and the knives close around the clips. The declipper can handle up to 30 chubs a minute, per set of declipping heads. Up to 3 sets of declipping heads available to maximize output. After cutting the clips, the knives retract, removing and discarding the clips in the process. Since the product is centered on the declipper belt, an optional sectioning knife mounted at the discharge of the declipping stations can accurately cut the product in half. From the declipper, chubs can be indexed directly to a slicing or packaging line without human contact. With all these timesaving features, the Declipper can be a welcome addition to your processing line.

Declipper

- Automated declipping eliminates human contact with RTE product.

- PLC controls index each chub into declipping head(s).

- Each head set declips both sides simultaneously, up to 30 pieces per minute.

- Accepts chub length variations of up to 2" (51 mm) per setting.

- Change settings quickly to handle chubs up to 6" diameter (153 mm).

- Quick disassembly for easy cleaning and inspection.

- Optional automatic sectioning knife.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Brine Mixing System

The Brine Mixing System is ideal for high volume mixing, chilling and storage applications, Now you can prepare meat brines or poultry marinades quickly and efficiently in a controlled system for perfect repeatability, batch after batch. The brine mixing process begins at the dry ingredients hopper which is placed at a convenient height for easy loading. When the hopper valve is opened, a vacuumizing action siphons the precise amount of ingredients into the preparation tank. Once ingredients are inside the tank, a powerful centrifugal pump circulates and homogenizes the mixture. Even hard-to-mix ingredients like phosphates, proteins, gums and starches can be thoroughly homogenized quickly. Stainless steel system with fine sanitary finish throughout. Custom designed storage tanks available in capacities up to 530 gallons (2000 liters).

Brine Mixing System

- Efficient, controlled mixing and chilling of meat brines and poultry marinades. Brines can be prepared as supersaturated solutions, with up to 30% heavy solids.

- Feeds directly to ancillary equipment or storage tanks.

- Capacities: 130 gallons (500 liters), 200 gallons (750 liters) and 260 gallons (1000 liters).

- Optional glycol jacketed cooling system available.

- Single propeller or reduction-head style agitator available to custom fit your application.

- Standard or programmable Allen-Bradley controls.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Inline Condiment Feeder

The In-line Condiment Feeder accurately mixes emulsion products with condiments such as olives, cheese, peppers, etc. As the meat emulsion passes through the system, a variable speed, condiment metering feedscrew delivers the condiment to formulate a consistent product, evenly distributed throughout.

Inline Condiment Feeder

- In-line system increases production and prevents overworking of emulsion batter by eliminating the double-back processing normally required to add condiments to emulsions.

- Condiment metering feedscrew with variable speed drive delivers consistent and even inclusion of olives, cheese, peppers, or other ingredients combined with meat product.

- Recipe-driven, PanelView controls.

- Agitator in condiment tub prevents bridging of product.

- Pump and main 9" (230 mm) diameter feedscrew driven by 20 hp (15 kW) gearmotor.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Tumbler Bamix

The Tumbler Bamix has been designed with the most advance technology and highest standards to offer the most efficient and precise massaging, mixing and churning in the food industry. Thanks to its optimum paddle design, high tech equipment and cleaning system, the Tumbler Bamix is used in multi-industry applications such as Salting, Marinating, Coating, Steam Cooking, Defrosting and Cryogenic mix-chilling.

Tumbler Bamix

- Best massaging & mixing precision

- Optimum product flexibility

- Optimum paddle design

- Food safety & traceability

- Integrated cleaning system

- Custom made Bamix to suit customer's need

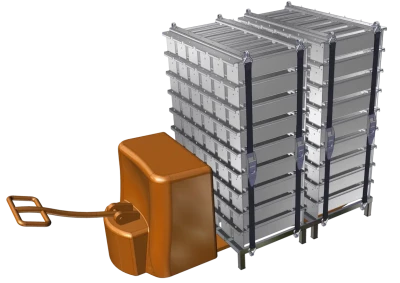

Kit Multimolds

The patented Multimolds kits are design to shape meat products for customers using other cooking and chilling technologies than the Thermix system. The Multimolds kits are used in different applications in the food processing industry.

Kit Multimolds

- The patented Multimolds kits are a 100% stainless steel custom design molds that guarantees total flexibility in products shapes.

- Optimum product shape consistency with accurate dimensions thanks to constant positive interlocks

- Uniform cooking thanks to specifically designed channels for the circulation of the heat transfer fluids

- Optimum hygienic conditions thanks to its sanitary design

- Custom made Multimolds to suit each customer’s need