- Home

- Industries

- Food

- Hot Dog

Hot Dog Equipment

A hot dog is a dish consisting of a grilled or steamed sausage served in the slit of a partially sliced bun. The term hot dog can also refer to the sausage itself. The sausage used is a wiener or a frankfurter. The names of these sausages also commonly refer to their assembled dish. Optimize your yield production with RGMTSI hot dog processing equipment. Reduce production time while maintaining consistent quality of your hot dogs.

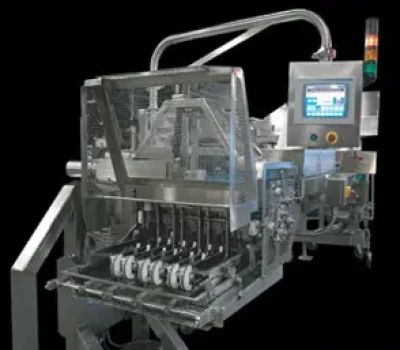

LS 1400 Launcher Style Loader

LS-1400 is the most sanitary launcher style high speed frankfurter loader on the market. This unit can handle skinless or skin-on, cooked and chilled and frozen frankfurters from 14 to 32mm diameters* and from 3 1/8” length (79.375mm) to 8 3/4” length (222.25mm). (*May require change of bucket conveyor, subject to final specification analysis.)

LS 1400 Launcher Style Loader

- The model LS-1400 can load up to 1400 pieces per minute of a 5” long (127mm) product with a 98% fill rate.

- All frankfurter loaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader. The Drake LS-1400 launcher style loader offers a compact footprint and a design that allows it to be stripped for cleaning in less than an hour. This unit’s launcher section utilizes sanitary food belts that easily remove for cleaning.

LS 1800 Launcher Style Loader

Launcher Style high speed Autoloaders are the most sanitary loaders on the market today. These units can handle skinless or skin-on, cooked and chilled products from 14 to 32mm in diameter* and from 3 1/8” length (79.375mm) to 8 3/4” length (222.25mm). (*May require change of bucket conveyor, subject to final specification analysis.)

LS 1800 Launcher Style Loader

- The model LS-1800 can load up to 1,800 pieces of a 5” long (127mm) product with a 98% fill rate.

- Autoloaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader.

- LS-1800 launcher style loader offers a compact footprint and a design that allows it to be stripped for cleaning in less than an hour.

- This unit’s launcher section utilizes sanitary food belts that easily remove for cleaning.

SR 400 Robot Autoloader

SR-400 open channel autoloader features an easy-to-operate robotic system to place various food products into multiple horizontal packaging configurations. The entire unit is operated by a single Allen Bradley LS-71 PLC to provide steady, reliable operating for years to come. The high-speed end of arm tooling (EOAT) robot has a 3kg payload. With high-quality materials, the EOAT is ideal to handle soft product such as natural casing and CoEx.

SR 400 Robot Autoloader

- The unit offers the hygienic design benefits of other launcher style loaders in a compact design ideal for smaller-sized packaging lines. With hygiene and safety in mind, all areas with moving parts of the SR-400 are completely guarded.

- The SR-400 loads up to 400 pieces per minute and can handle a variety of products up to 200 mm (8 inches) in length, making it ideal for packaging lines operating at 0.6 to 1 ton per hour capacity. The SR-200 model provides 200 pieces per minute capacity.

- Loads both bulk and retail packages. Multiple count and multiple layers are easily and quickly changed from one package or product to another. The model SR-400 is exceptionally durable. The stainless steel open frame and robot is able to withstand the severe sanitation procedures used in RTE environments.

- Using your existing cutter, the SR-400 can also be adapted to most conveyor-type cutting or barrel delinker.

- All autoloaders feature touch screen controls, allowing for easy addition of new recipes and rapid adjustment to various areas of the loader.

CS Canning System

CS-Canning System is designed for loading speeds up to 400 cans per minute at seven sausages per can. The system allows manufacturer to electronically program multiple sausage counts per can. Long sausages are fed into the optional Slicer (below right), which cuts them into equal length pieces. The cut pieces are dropped onto a conveyor, go through a metal detector, and then feed into a collator to gain product alignment. The product drops from the collator onto a grouping conveyor and then into the canner.

CS Canning System

- You thought there was a placeholder text here, but it was me DIO!

CS 900 Corn Dog Loader

CS-900 integrates into a corn dog batter/frying line. The unit automatically feeds cooked and peeled sausages onto a continuous moving flighted conveyor belt. At this point, product is presented to the auto-skewer section of the corn dog fryer. Skinless, cooked and chilled frankfurters from 16 to 32mm in diameter are within the acceptable standards. This Loader aligns product on the fryer conveyor at up to 26 hot dogs per index, resulting in the processing of 16,000 pieces/hour. Thus, meeting the fryer’s speed and product supply requirements. An elevating supply conveyor may be added to this system to feed product into the CS-900.

CS 900 Corn Dog Loader

- You thought there was a placeholder text here, but it was me DIO!