- Home

- Industries

- Food

- Pet Food

Pet Food Equipment

Pet food is animal feed intended for consumption by pets. Typically sold in pet stores and supermarkets, it is usually specific to the type of animal, such as dog food or cat food. Most meat used for animals is a byproduct of the human food industry, and is not regarded as "human grade". We have a wide range of production lines for pet food processing, designed specifically to cope with the unique characteristics of these products.

PrimeMove Inclined Screw Loader

Screw Loaders (CSL) are ideal for storing and transferring products from dumpers, mixers, conveyors and other sources. The heavy-duty inclined screw loader utilizes a feedscrew that discharges directly onto various ancillary systems.

PrimeMove Inclined Screw Loader

- Unique, quick-release, watertight shaft seals for full washdown sanitation.

- Heavy duty, stainless feedscrew auger is available in diameters from 9" (230 mm) to 20" (500 mm).

- Wide range of hopper sizes, discharge angles and heights custom-made to your requirements.

- CSL units available in capacities ranging from 2000 lbs. to 8000 lbs. (900 kg-3600 kg).

- Optional agitator is available to prevent bridging of product.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Horizontal Screw Loader

Horizontal Screw Loaders are ideal for storing and transferring products from dumpers, mixers, conveyors and other sources. The heavy-duty horizontal screw loader utilizes a feedscrew in combination with a vane pump that transports product via piping for delivery to the next processing station.

PrimeMove Horizontal Screw Loader

- Unique, quick-release, watertight shaft seals for full washdown sanitation. 9" (230 mm) diameter heavy duty, stainless feedscrew auger.

- Optional agitator is available to prevent bridging of product.

- CSL units available in capacities ranging from 500 lbs. (230 kg) to 10,000 lbs. (4500 kg).

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

Stuffing Hoppers (CSH) are designed to integrate seamlessly into today's high volume, continuous processing lines. Direct-discharge valving systems enable CSH units to automatically receive product from upstream units. This greatly reduces or in many cases, completely eliminates human labor associated with handling and transporting of product, thus eliminating product contamination. The modular CSH system can be custom configured from one to multiple chamber units and can be equipped with numerous options to maximize the efficiency of your specific operation. Our CSH units are especially useful when incorporated into a complete emulsion/reduction line.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

- Each hopper utilizes an independent hydraulically driven, stainless steel, positive displacement (PD) pump.

- Bypass valves are completely eliminated and steady line pressures of 70-80 psi (4.8-5.5 bars) are maintained for exact finished product weight.

- Custom designed hoppers to fit your production requirements and floor plan.

- Quick-release coupling device between hopper throat and PD pump and easily accessible pump rotors for thorough sanitation.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Transfer Hopper with Stainless PD Pump

The custom designed Transfer Hopper with PD Pump fits cleanly under a mixer / blender in a emulsion line. Designed to transfer to a storage silo or other large vessel, the transfer hopper easily spans the width of the mixer discharge area to eliminate product spillage. The powerful positive displacement pump eliminates the need to elevate the upstream equipment to fully empty a mixer. Pump silos can store enough blended material to continuously feed the emulsion system. When used downstream of the emulsifier, the transfer hopper can provide a continuous feed into stuffers or linkers.

PrimeMove Transfer Hopper with Stainless PD Pump

- Capacities to fit your application with sizes up to 20,000 lbs. (9,100 kg)

- Transfer rates up to 1,000 lbs/minute (450 kg/min.) using our PD650 pump

- Eliminates the need to elevate the upstream equipment to fully empty a mixer

- Available with our 500, 575 or 650 PD pumps depending on the application

- Electric or hydraulic powered pump

- Pivoting pump base for easy sanitation

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design

PrimeMove VSS-3 Vacuum Stuffing / Filling System

When it comes to high volume, continuous-flow, vacuum stuffing and filling applications, the Vacuum Stuffer (VSS) series stands in a performance class by itself. With the unique VSS design, improved / consistent finished product vacuum levels and high volume flow rates are ensured. The VSS utilizes dependable hydraulic power. A fully integrated heat exchanger keeps hydraulic fluid cool for dependable operation even under extended periods of heavy usage. From fine emulsions and coarse reductions, to sectioned, whole muscle mixtures, VSS brings a new level of efficiency and economy to any high volume stuffing / filling system.

PrimeMove VSS-3 Vacuum Stuffing / Filling System

- Vacuum stuffing capacity: Up to 28,000 lbs. (12,700 kg) per hour, depending on product.

- Variable speed vane pump, feedscrew and agitator are powered by a heavy-duty hydraulic drive system.

- Vacuum cover opens and closes pneumatically. For operator safety, an interlock device prevents the lid from accidental closure.

- Quick and easy vacuum loading.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

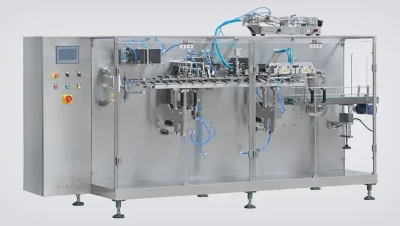

Premade Pouch Fully Automatic Packaging Machine

Premade Pouch Fully Automatic Packaging Machine is suitable for the ready-made pouches packaging used for liquids, powders, granules, sauces etc. It can work with different bag variations, which can open up possibilities to different pouch / bag appearance and design from sthe standard stand-up pouches, zipper bags, accordion pockets to free shape bags. This in turn meets the demands of product variety while maintaining high speed production.

Premade Pouch Fully Automatic Packaging Machine

- Uses constant heat sealing

- Uses press bar cooling

- Recommended bag pattern: premade pouch, laminated film

- Speed: 20-50 pcs/min depending on the fluidness of products

- Available in single or double bag operation

Horizontal Premade Pouch Fully Automatic Packaging Machine

Premade Pouch Fully Automatic Packaging Machine is suitable for the ready-made pouches packaging used for liquids, powders, granules, sauces etc. It can work with different bag variations, which can open up possibilities to different pouch / bag appearance and design from sthe standard stand-up pouches, zipper bags, accordion pockets to free shape bags. This in turn meets the demands of product variety while maintaining high speed production.

Horizontal Premade Pouch Fully Automatic Packaging Machine

- Recommended bag pattern: premade pouch, laminated film

- Speed: 20-70 pcs/min depending on the fluidness of products

- Available in single or double bag operation

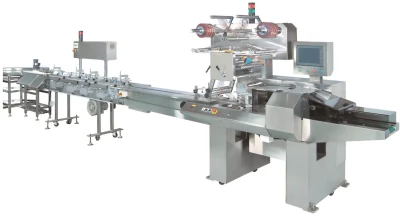

Horizontal Standard Flow Wrapper

The Horizontal Standard Flow Wrapper Machine has the merit of both mechanical and digital control, product changeover easily, colored HIM for key in data also able to cope with semi-auto feeding to increase the packaging speed. Applicable in most product you can imagine inside a wrapper, masks, pet food, bread, cakes, moon cakes, instant noodles, biscuits, snacks, pastry products, productive wrapping of boxed products, candy, blisters, cosmetics products, toy industry, cards and many more.

Horizontal Standard Flow Wrapper

- User-friendly human machine interface control with 4.3inch touch screen for convenient operations

- Compact construction for reducing space required

- Bag length indication ensures fast and accurate length adjustment

- Optional feeding systems are available for various products

- Equipped with precision photocell sensor for film tracing control

- The machine stops automatically when the film runs out

- Four sets of temperature controllers

- All product-contacted areas are in stainless steel or plastic construction

Horizontal Compact Flow Wrapper

Horizontal Compact Flow Wrapper Machine is entry level for flow wrapper with compact design and reasonable price, suitable for packaging product simple or similar size. Applicable in most product you can imagine inside a wrapper, masks, pet food, bread, cakes, moon cakes, instant noodles, biscuits, snacks, pastry products, productive wrapping of boxed products, candy, blisters, cosmetics products, toy industry, cards and many more.

Horizontal Compact Flow Wrapper

- Compact construction for reducing space and cost requirement

- Bag length is easy adjusted by the indicator

- Equipped with precision photocell sensor for tracing control

- Auto-stop for out of film

- Efficiently working performance and labor saving

- All product-contacted areas are in stainless steel or plastic construction

Horizontal Automatic Packaging Machine

Horizontal Automatic Packaging Machine reduces labor costs while maintaining high productivity output on long and continuous operation. The most notable feature of this packaging machine is its regimented processing of products. Its inline feeder offers high flexibility to the packaging line. Multiple belt conveyor system with automatic control of the speed of each belt enhances the capacity and efficiency. The speed of inline feeder is synchronized to the flow wrapper by the vacuum belt driven by the servo motor. The system is used for high speed inline feeding of regular shaped product such as cookies ,chocolate bars. etc. Applicable products includes the following but are not limited to Cake, Chocolate, Credit Card, Ice Cream, Biscuit, Frozen Food and similar products.

Horizontal Automatic Packaging Machine

- Durable, high productivity and low-noise by 4 independent servo motors with electronic control enable 24hours nonstop high speed packaging

- User-friendly human / machine interface control with 10.4inch colorful monitor and Dialogue type screen provides maximum operational convenience and is easy to learn

- Comply with PIC/S-GMP specification and also equips USB port and automatic saving event log

- 50 sets of recipe (bag length, temperature, speed, feeding position, film tension and cutting position) could reduce the initial lose providing high efficiency

- High compatibility with different feeding systems: Desiccant dispenser, Card Magazine, Product Orientation Systems (for round product), Row distribution systems (for bar-shape product) and belt type feeding system... etc.

- Optional to (a) Auto Splicer (b) bar code reader (c) Rejection function