- Home

- Industries

- Food

- Processed Meat

Processed Meat Equipment

Processed meat is meat that has been preserved by curing, salting, smoking, drying or canning. Food products categorized as processed meat include: Sausages, hot dogs, salami. Ham, cured bacon. RGMTSI has a large selection of meat processing equipment and products including grinders, sausage stuffers, mixers, dehydrators, saws, smokers and more!

VCS Batter Mixer

Batter Mixer

VCS Batter Mixer

- Ultrasonic in-line viscometer controlling a wide range of viscosities with extremely tight tolerances. No calibration required. CIP capable

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Fully automated controls using an AB PLC & color touchscreen for 100% automated control of batter mixing and monitoring

- All stainless steel viscosity pump and motor with direct drive

- Stainless steel 2 HP mixer

- Sanitary stainless steel water piping

- Stainless steel feed pump and motor with direct drive are controlled using variable frequency drives for speed and flow control

- Ergonomically designed low profile batter hopper available in standard 34” load height with 100 lb. capacity

- Can produce batter with tolerances of less than one-third of a cup second, which equals 5-6 centipoise

- Stainless sanitary piping

- Out-of-spec alarm system monitoring temperature and motor overloads

- Perforated parts basket for all sanitary and pump parts

- High efficiency, stainless steel mix tank w/cooling jacket on exterior of side and bottom of tank (180 PSI A.S.M.E. Certified/Stamped)

MiniJet

As more and more facilities feel the pressure of labor, tighter customer specifications, and increased volumes, RGMTSI has responded to these needs with the MiniJet. As the most compact overall water cutting system, the MiniJet offers 1 lane of production with 2 XY cutters and still maintains the integrated on-board high pressure pump. The MiniJet is ideal for those looking for an introduction to water cutting, trimming fat for visually lean products after a de-bone line, steak trimming, or simple portioning. The MiniJet boasts all the features and applications you have come to expect in a water cutter, all in a 14' footprint, that can fit almost anywhere. All 3 machines offer remote trouble shooting with a webcam for quick analysis or product development. They both also include charting and trending for production standards and goals or preventive maintenance needs. Both machines come fully equipped with a dependable and current servo drive, with no risk of becoming obsolete after install. RGMTSI is also pleased to provide customers with constant and complimentary software upgrades to ensure applications, features, and technology are always up-to-date. If you are new to water cutting or interested in learning more, please feel free to contact your RGMTSI sales representative today.

MiniJet

- You thought there was a placeholder text here, but it was me DIO!

MegaJet Jr

The MegaJet Jr. is a high speed, high accuracy, easy to use water cutter. It was designed to offer users a more cost efficient, user friendly, and higher technology water cutter. The MegaJet Jr. offers 4 XY cutters and 2 stationary dual nozzle cutters on two lanes of production, cutting product at speeds up to 80 feet per minute. Some of the features include a fully integrated on-board high pressure pump, simple yet high-tech camera design, windows operating system, and touch screen user interface. The MegaJet Jr. is ideal for customers who have a need for water cutting, are new to water cutting, or want to upgrade their facility to include the newest technology in water cutting. The MegaJet Jr. has all the cut applications that any user could imagine or desire.

MegaJet Jr

- You thought there was a placeholder text here, but it was me DIO!

MegaJet

With the growing demand for increased volume, RGMTSI developed and released the first 8 XY cutter machine the industry has ever seen. With 8 XY cutters, intelligent cut paths, and a wide production belt, the MegaJet is our highest volume water cutter. The MegaJet has all the features IntelliJet customers have grown to expect such as, the fully integrated on-board pump, state of the art camera system, windows operating system, and touch screen controls. The MegaJet also comes fully upgraded with SureLok door lock upgrades, and the PES Flex Hose assembly. The MegaJet is ideal for customers who want to portion over 15,000 pounds per hour, need to cut product to keep further processing lines full, want to ensure a high quality product for their customers, or need to replace outdated water cutters in their plant. The MegaJet as all the cut applications that a user could dream of or desire.

MegaJet

- You thought there was a placeholder text here, but it was me DIO!

Fillet Splitter

As a way to greatly reduce labor for plants that are natural falling or selling line run fillets, RGMTSI has developed the Fillet Splitter. Our Fillet Splitter utilizes high pressure water to split boneless skinless butterfly breasts into fillets at rates of up to 100 butterflies per minute per lane. Since all our equipment is custom built to fit specific needs, customers can select their desired infeed and outfeed lengths, number of lanes of production, and height off the floor. As with all our equipment, the Fillet Splitter utilizes food grade stainless steel, plastics and belting. The Fillet Splitter comes fully equipped with door guards, E-Stops, and a relief valve to ensure the highest level of safety. If your customer has strict requirements on keel removal, there is no need for additional labor, we can develop your Fillet Splitter to remove keel ribbon and provide your customers with the outstanding product they are expecting. There are endless possibilities with the Fillet Splitter, so call your Sales Representative today to discuss options you may have in mind.

Fillet Splitter

- You thought there was a placeholder text here, but it was me DIO!

Marination System

As the critical starting point for your further processing lines, consistent marination is essential for your success. RGMTSI is pleased to offer a fully integrated brine marination mixing system. By utilizing high shear mixing options, automatic ingredient loading, recipe controls,heat exchangers, and temperature controls, RGMTSI's Master Marination System is the fully integrated solution for all you marination mixing needs.

Marination System

- You thought there was a placeholder text here, but it was me DIO!

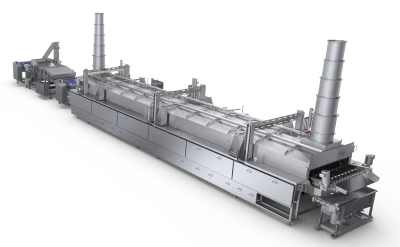

Batter, Breading, And Frying Lines

RGMTSI offers fully integrated Batter, Breading, and Frying lines. Each machine in the line can be controlled from a single HMI Panel, giving one operator complete control over several pieces of equipment. Lines can be customized to fit your processing needs by utilizing our batter and equipment in any order you choose.

Batter, Breading, And Frying Lines

- You thought there was a placeholder text here, but it was me DIO!

TCS Batter Mixer

Batter Mixer

TCS Batter Mixer

- An ALL electric automated tempura batch mixing system with very precise mix accuracy and temperature control

- Standards & guidelines to Food Safety & USDA requirements

- Construction is all stainless steel frame and assembled using US standard food safety components

- Capable of producing up to 660 gallons of tempura per hour or as little as 25 gallon per hour. The TCS can mix and pump a batch of tempura in 5 minutes or less.

- High efficiency 50 or 70 gallon insulated tanks

- Adjustable batch size that is 100% programmable

- All stainless steel Unibloc PD feed pump with variable speed

- All stainless steel direct driven mixer with precise speed control of a VFD

- All stainless steel water and sanitary piping

- All stainless steel jacketed & insulated mix tank with jackets on side & bottom of tank (180 psi ASME Certified & Stamped)

- Ergonomically designed low profile hopper with 150lb capacity

- Self-diagnostics for alarms, temperatures and motor O.L.

- Perforated parts basket for all sanitary and pump parts during disassembly

MP115 Flat Breader

Flat Breader

MP115 Flat Breader

- Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

- Flour coating configuration

- Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

- MP rotating top flow breading distribution system

- Standard casters with stainless steel frame and Phenolic Wheels

- Rotating belt vibrator

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

- Positive cam/lock on all access doors

- Lift cylinder on discharge chute, hopper and covers

- Adjustment/support for discharge of batter applicator

- Belt tension adjustment for hopper/main belt

- Stand-off bearings for maximum sanitary design

- Engineered for safety, user friendliness and optimum uptime

- Operator controls ergonomically designed

- Designed for 40” and 52” usable belt width

MP116 J Crumb Breader

Crumb Breader

MP116 J Crumb Breader

- Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

- Flour coating configuration for free flow and Japanese crumb coatings

- Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

- Rotating top flow breading distribution system

- Standard casters with stainless steel frame and Phenolic Wheels

- Rotating belt vibrator

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

- Positive cam/lock on all access doors

- Lift cylinder on discharge chute, hopper and covers

- Adjustment/support for discharge of batter applicator

- Belt tension adjustment for hopper/main belt

- Stand-off bearings for maximum sanitary design

- Engineered for safety, user friendliness and optimum uptime

- Operator controls ergonomically designed

- 40” usable belt width