- Home

- Industries

- Food

- Processed Meat

Processed Meat Equipment

Processed meat is meat that has been preserved by curing, salting, smoking, drying or canning. Food products categorized as processed meat include: Sausages, hot dogs, salami. Ham, cured bacon. RGMTSI has a large selection of meat processing equipment and products including grinders, sausage stuffers, mixers, dehydrators, saws, smokers and more!

MP120 Drum Breader

Drum Breader

MP120 Drum Breader

- All stainless steel drum provides unmatched durability and maximum production capability

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Heavy-duty drum drive support system provides positive drum drive without slipping

- Exclusive MP direct auger transfer system helps eliminate breading jamming and provides efficient transfer with less breading in machine

- Extended vertical screw housing provides more efficient breading transfer into drum without vibrators

- Includes automatic “crumb” removal system and allows precise removal of moist crumbs from flour

- Standard right hand controls, option for left hand

- One piece aluminum hydraulic manifold with stainless steel hydraulic flow control valves provides precise motor speed control

- Durable, non-rusting valves

- 10-60 FPM variable speed hydraulic drives with plated motors

- Quick disconnect couplings for easy motor change out

- Separate variable speed direct drive augers eliminates chains, sprockets and gear boxes and provides precise individual speed control

- “gull wing” door system with lift cylinders allows complete access to machine for sanitation and maintenance

- Hood provides fully enclosed drum and drive system and reduces airborne dust

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

MP900 Advantage Frying System

The ADVANTAGE Frying System with state-of-the-art thermal heating leads the industry with technology that improves operating characteristics and costs of frying quality foods - the most efficient heat exchange process in the industry. After several years in development, we’ve designed and manufactured the industry’s most efficient heat exchange process. Our heat exchanger features the ADVANTAGE HelyX insert that redirects the flow of thermal fluid into a helical path, delivering balanced heat side-to-side and infeed to discharge.

MP900 Advantage Frying System

- Available in 40” and 52” widths and 25', 30', and 35' lengths

- High capacity

- High efficiency

- Fast heat recovery and control

- Low cooking oil volume

- Quick clean up time

- Low operating costs

Tumbler Bamix

The Tumbler Bamix has been designed with the most advance technology and highest standards to offer the most efficient and precise massaging, mixing and churning in the food industry. Thanks to its optimum paddle design, high tech equipment and cleaning system, the Tumbler Bamix is used in multi-industry applications such as Salting, Marinating, Coating, Steam Cooking, Defrosting and Cryogenic mix-chilling.

Tumbler Bamix

- Best massaging & mixing precision

- Optimum product flexibility

- Optimum paddle design

- Food safety & traceability

- Integrated cleaning system

- Custom made Bamix to suit customer's need

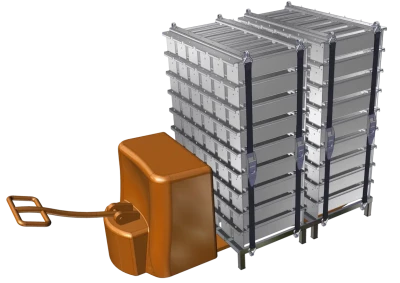

Kit Multimolds

The patented Multimolds kits are design to shape meat products for customers using other cooking and chilling technologies than the Thermix system. The Multimolds kits are used in different applications in the food processing industry.

Kit Multimolds

- The patented Multimolds kits are a 100% stainless steel custom design molds that guarantees total flexibility in products shapes.

- Optimum product shape consistency with accurate dimensions thanks to constant positive interlocks

- Uniform cooking thanks to specifically designed channels for the circulation of the heat transfer fluids

- Optimum hygienic conditions thanks to its sanitary design

- Custom made Multimolds to suit each customer’s need

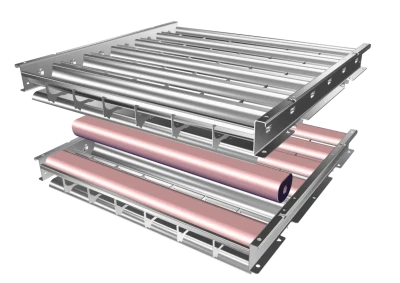

Multimolds for Shaped Ham Logs

Complementary to the Thermix, Multimolds enable molding and handling of products in the Thermix system throughout the whole process. Thanks to their specific shape for each different products, Multimolds enable versatility and are suitable for all kind of products. The patented Multimolds system is very compact and guarantees consistency of the products shape and dimensions as well as a precise homogenous cooking. Multimolds can also be used in some traditional cooking and chilling equipment. 100% stainless steel, Multimolds™ are robust, easy to maintain and easy to clean.

Multimolds for Shaped Ham Logs

- Optimized loading capacity improved by 20 to 30% regards to traditional systems.

- Compatible with automated solutions to load & unload the products.

- Versatile in the product dimensions between logs or delis/loafs.

- Perfectly constant pressing on products resulting in homogeneous products.

- Constant homogenity of slices guaranted no more than +/- 2 mm.

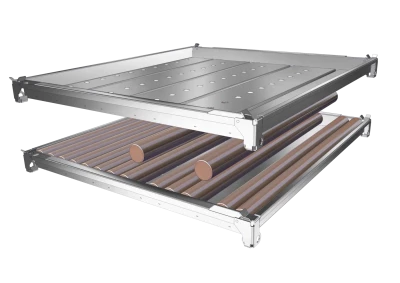

Multimolds for Deli Hams

Complementary to the Thermix, Multimolds enable molding and handling of products in the Thermix system throughout the whole process. Thanks to their specific shape for each different products, Multimolds enable versatility and are suitable for all kind of products. The patented Multimolds system is very compact and guarantees consistency of the products shape and dimensions as well as a precise homogenous cooking. Multimolds can also be used in some traditional cooking and chilling equipment. 100% stainless steel, Multimolds™ are robust, easy to maintain and easy to clean.

Multimolds for Deli Hams

- Optimized loading capacity improved by 20 to 30% regards to traditional systems.

- Compatible with automated solutions to load & unload the products.

- Versatile in the product dimensions between logs or delis/loafs.

- Perfectly constant pressing on products resulting in homogeneous products.

Multimolds for Round logs

Complementary to the Thermix, Multimolds enable molding and handling of products in the Thermix system throughout the whole process. Thanks to their specific shape for each different products, Multimolds enable versatility and are suitable for all kind of products. The patented Multimolds system is very compact and guarantees consistency of the products shape and dimensions as well as a precise homogenous cooking. Multimolds can also be used in some traditional cooking and chilling equipment. 100% stainless steel, Multimolds™ are robust, easy to maintain and easy to clean.

Multimolds for Round logs

- Optimized loading capacity improved by 20 to 30% regards to traditional systems.

- Compatible with automated solutions to load & unload the products.

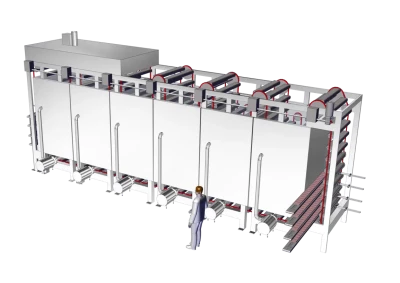

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

Industrial Rooms for CMP

CMP is short for Continuous Maturing Process and represents our continuous maturation system. With this technology, we distinguish ourselves from all other systems through shorter processing times, product uniformity combined with increased product capacity. This unique system is able to perform the maturing and drying process without any breaks. Due to the control of relative humidity and temperature for inlet and outlet air, it is possible to dry products without any variation. The system is able to move the air continuously (100% of the time) without any rest period.

Industrial Rooms for CMP

- Complete consistency means less than 1% deviation in the entire processing room

- Saving up to 30% processing time

- Significant energy savings

- Optimal utilisation of footprint and room height with full trolley loading up to 6 m in height

- Up to 250% more product can be produced in the same footprint than with comparable systems.

Industrial thawing systems ATA

The optimal system for balanced thawing without much weight loss. This thawing system has the best prerequisites for consistent quality in the subsequent processes.

Industrial thawing systems ATA

- Consistent thawing with high loading capacity

- Variable: The customer can supply the processing room from insulated panels or insulated brickwork.

- Minimum energy consumption: The system’s energy supply is chosen so that the target values can be rapidly achieved. All thawing processes can be controlled and regulated via the operating temperature, the core temperature or the peripheral temperature.

- Environmentally friendly: Minimum energy consumption: Individual air circulation systems and fresh air / exhaust air controls for each trolley place considerably reduce process times and thus energy requirements. Each trolley place is processed at the same temperature and relative humidity.