- Home

- Industries

- Food

- Processed Meat

Processed Meat Equipment

Processed meat is meat that has been preserved by curing, salting, smoking, drying or canning. Food products categorized as processed meat include: Sausages, hot dogs, salami. Ham, cured bacon. RGMTSI has a large selection of meat processing equipment and products including grinders, sausage stuffers, mixers, dehydrators, saws, smokers and more!

AllroundSystem ASR

The flexible and space-saving system solution for smoking and cooking. From smouldering and friction to liquid smoke – the customer has the choice. Due to the AllroundSystem, the production possibilities are virtually unlimited.

AllroundSystem ASR

- Wide variety of flavours and colours: Various external and internal smoke generation systems such as smouldering smoke, condensate smoke, friction smoke or liquid smoke, are available for smoking.

- Efficiency: The strongest air circulation guarantees consistent product quality with minimum weight loss during drying and smoking despite maximum trolley loading.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PRR

ProfitLine systems are universal allrounders due to the horizontal and vertical air circulation, regardless whether products are placed horizontally on mesh shelves or suspended on smokesticks. The enormous air circulation allows for uniform product quality with the least weight loss.

ProfitLine PRR

- Wide variety of flavours and colours: All external and various internal smoke generation systems, such as smouldering smoke, condensate smoke, friction smoke or liquid smoke, are available for smoking.

- Efficiency: Due to two fans an extensive air circulation guarantees constant product quality with minimum weight loss upon drying and smoking despite maximum trolley loading.

- Designed for industry: The central air conditioning system incorporates all required equipment such as a heat exchanger, a central circulation fan, an air alternating damper, fresh air and smoke supplies and a mixing chamber for air conditioning.

- Minimum energy consumption: Individual air circulation and optimal use of fresh air energy during drying enormously reduce your process times and thus the energy requirements. The system as well as the air handling unit are fully insulated.

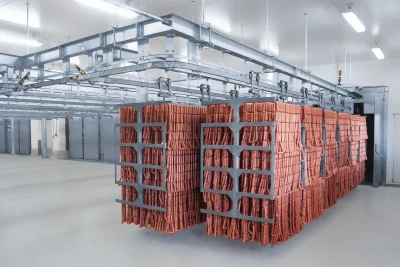

Semi continuous batch system KCS

The production process takes place continuously in a continuous batch system; from filling to packaging, there is no delay in the processing of products.

Semi continuous batch system KCS

- “Inline” production: The production process is performed inline with the semicontinuous loading system, i. e. there is no processing delay between filling and packaging.

- 100% Separation between low and high risk areas: The airtight transfer zone between the entry and exit sides allows the separation of production and packaging areas (“low-risk“, “high-risk“).

- Integration: The system can be integrated into the production area due to upstream and downstream automation.

Universal circulation system KK

Especially developed for these processes, these systems are efficient in the processing of products and can be customized as a solution for industry and craft.

Universal circulation system KK

- Low investment costs: The systems are specially developed for the cooking process in order to guarantee low investment costs for a high production capacity.

- Efficiency: The optional air circulation system guarantees excellent product flexibility so that e.g. ham can be produced in various moulds despite high trolley loading.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

Steam inject circulation cooking system SKU

Space-saving and cost-effective: thanks to its slim dimensions, this cooking system is the perfect solution for every craft and industrial company.

Steam inject circulation cooking system SKU

- Low investment costs: The systems are specially developed for the cooking process in order to guarantee low investment costs for a high production capacity.

- High product quality: A consistent and reproducible product quality with low process costs is achieved thanks to the technically sophisticated direct steam injection system in the cabinet.

- Efficiency: The air circulation guarantees a high product flexibility.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PK

Cooking with low investment costs and high production capacities? Guaranteed by ProfitLine PK.

ProfitLine PK

- Low investment costs: The systems are specially developed for the cooking process in order to guarantee low investment costs for a high production capacity.

- High product quality: A consistent and reproducible product quality with low process costs is achieved thanks to the technically sophisticated direct steam injection system in the cabinet.

- Designed for industry: Wide door opening clearance.

Cooking kettles FK

An energy-saving and universally applicable solution for all cooking processes in different installation variations.

Cooking kettles FK

- Simple and effective cooking: The modern control of the cooking kettles fulfils everything that is required. The control is easy to handle and shows the set target performance comparison at any time. It saves the programs until a new program is entered. It offers broad alternatives of any kind of control system.

- Delta-t-cooking with the kettle: With the technology of RGMTSI sensitive quality products such as cooked ham can be produced without any problems.

- Valuable investment: The interior of the kettle is manufactured of stainless steel (1.4571 / AISI 316). This guarantees a highest possible corrosion resistance and thus a long economic life time.

- Low energy consumption: Outstanding heat retention is one feature of kettles. Electrically heated kettles have optimal heat transfer to the cooked products.

AllroundSystem ARQ

Optimal air circulation and air volume ensure a uniform product. Operating temperatures are reached quickly and maintained at a constant level thanks to efficient system isolation.

AllroundSystem ARQ

- Consistent product results: Horizontal air circulation, suction and the adaptation of the air quantity to products guarantee constant and reproducible production results.

- High loading capacity: Thanks to the horizontal air circulation, all products, such as baked sausage meat in various moulds, with minimum vertical clearances (min. 5 cm above the product) can be loaded onto the oven trolley. The systems therefore offer a maximum loading and product capacity.

- Efficiency: The system’s energy supply is selected so that the set values can be rapidly achieved. The cabinet insulation maintains the operating temperature over a long period. Short process times thanks to exceptionally high quantities of circulating air lead to a lower weight loss and therefore to a higher production capacity.

Intensive cooling system IUL

Fast and controlled cooling of products reduces unnecessary weight loss and increases production output. Individually tailored solutions can be developed for both larger industrial or smaller trade companies.

Intensive cooling system IUL

- Improved product quality: The shelf life of products is extended as quickly cooled and fresh goods are packed. Controlled cooling of products reduces unnecessary weight loss and increases production output.

- Efficiency: Shorter process times are achieved by pre-cooling with a water shower and the integrated misting system. Savings on cooling costs as the energy of outside air is used to its full potential.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PUR

Among other things, this ProfitLine offers the possibility of pre-cooling products with a water shower, which makes work processes effective, fast and energy-saving.

ProfitLine PUR

- Improved product quality: The shelf life of products is extended as quickly cooled and fresh goods are packed. Controlled cooling of products reduces unnecessary weight loss and increases production output.

- Efficiency: Shorter process times are achieved by pre-cooling with a water shower and the integrated misting system. Savings on cooling costs as the energy of outside air is used to its full potential.

- Designed for industry: Cooling capacity adjustable to product