- Home

- Industries

- Food

- Sausage

Sausage Equipment

A sausage is a type of meat product usually made from ground meat, often pork, beef, or poultry, along with salt, spices and other flavourings. Other ingredients such as grains or breadcrumbs may be included as fillers or extenders. RGMTSI offers high-quality meat processing equipment, jerky and sausage making supplies, and food preparation tools. We focus on making your production line fast and efficient while maintaining high-quality product.

CPD Positive Displacement Pumping System

Ideal for pumping sausage or ground beef chubs.

CPD Positive Displacement Pumping System

- Provides accurate, consistent pumping rates with high volume and low temperature rise.

- Output capacity of up to 50,000 lbs per hour [22,680 kg/hr].

- Available in 3 pump sizes: PD500, PD575, PD650.

- Stainless steel pump housing and gearbox.

- Disassemble for sanitation without tools.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

Stuffing Hoppers (CSH) are designed to integrate seamlessly into today's high volume, continuous processing lines. Direct-discharge valving systems enable CSH units to automatically receive product from upstream units. This greatly reduces or in many cases, completely eliminates human labor associated with handling and transporting of product, thus eliminating product contamination. The modular CSH system can be custom configured from one to multiple chamber units and can be equipped with numerous options to maximize the efficiency of your specific operation. Our CSH units are especially useful when incorporated into a complete emulsion/reduction line.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

- Each hopper utilizes an independent hydraulically driven, stainless steel, positive displacement (PD) pump.

- Bypass valves are completely eliminated and steady line pressures of 70-80 psi (4.8-5.5 bars) are maintained for exact finished product weight.

- Custom designed hoppers to fit your production requirements and floor plan.

- Quick-release coupling device between hopper throat and PD pump and easily accessible pump rotors for thorough sanitation.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Transfer Hopper with Stainless PD Pump

The custom designed Transfer Hopper with PD Pump fits cleanly under a mixer / blender in a emulsion line. Designed to transfer to a storage silo or other large vessel, the transfer hopper easily spans the width of the mixer discharge area to eliminate product spillage. The powerful positive displacement pump eliminates the need to elevate the upstream equipment to fully empty a mixer. Pump silos can store enough blended material to continuously feed the emulsion system. When used downstream of the emulsifier, the transfer hopper can provide a continuous feed into stuffers or linkers.

PrimeMove Transfer Hopper with Stainless PD Pump

- Capacities to fit your application with sizes up to 20,000 lbs. (9,100 kg)

- Transfer rates up to 1,000 lbs/minute (450 kg/min.) using our PD650 pump

- Eliminates the need to elevate the upstream equipment to fully empty a mixer

- Available with our 500, 575 or 650 PD pumps depending on the application

- Electric or hydraulic powered pump

- Pivoting pump base for easy sanitation

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design

PrimeMove VSS-3 Vacuum Stuffing / Filling System

When it comes to high volume, continuous-flow, vacuum stuffing and filling applications, the Vacuum Stuffer (VSS) series stands in a performance class by itself. With the unique VSS design, improved / consistent finished product vacuum levels and high volume flow rates are ensured. The VSS utilizes dependable hydraulic power. A fully integrated heat exchanger keeps hydraulic fluid cool for dependable operation even under extended periods of heavy usage. From fine emulsions and coarse reductions, to sectioned, whole muscle mixtures, VSS brings a new level of efficiency and economy to any high volume stuffing / filling system.

PrimeMove VSS-3 Vacuum Stuffing / Filling System

- Vacuum stuffing capacity: Up to 28,000 lbs. (12,700 kg) per hour, depending on product.

- Variable speed vane pump, feedscrew and agitator are powered by a heavy-duty hydraulic drive system.

- Vacuum cover opens and closes pneumatically. For operator safety, an interlock device prevents the lid from accidental closure.

- Quick and easy vacuum loading.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Declipper

Automate the process of removing wire clips on the ends of chubs with the Declipper. Safeguard your ready-to-eat products from the risk of contamination by eliminating inefficient manual declipping with this productivity-boosting machine. Feeding directly from a Chub Separator or manually, the infeed conveyor indexes the product to the declipping head stations and then stops. The declipping heads simultaneously approach the product from both sides and the knives close around the clips. The declipper can handle up to 30 chubs a minute, per set of declipping heads. Up to 3 sets of declipping heads available to maximize output. After cutting the clips, the knives retract, removing and discarding the clips in the process. Since the product is centered on the declipper belt, an optional sectioning knife mounted at the discharge of the declipping stations can accurately cut the product in half. From the declipper, chubs can be indexed directly to a slicing or packaging line without human contact. With all these timesaving features, the Declipper can be a welcome addition to your processing line.

Declipper

- Automated declipping eliminates human contact with RTE product.

- PLC controls index each chub into declipping head(s).

- Each head set declips both sides simultaneously, up to 30 pieces per minute.

- Accepts chub length variations of up to 2" (51 mm) per setting.

- Change settings quickly to handle chubs up to 6" diameter (153 mm).

- Quick disassembly for easy cleaning and inspection.

- Optional automatic sectioning knife.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

Inline Condiment Feeder

The In-line Condiment Feeder accurately mixes emulsion products with condiments such as olives, cheese, peppers, etc. As the meat emulsion passes through the system, a variable speed, condiment metering feedscrew delivers the condiment to formulate a consistent product, evenly distributed throughout.

Inline Condiment Feeder

- In-line system increases production and prevents overworking of emulsion batter by eliminating the double-back processing normally required to add condiments to emulsions.

- Condiment metering feedscrew with variable speed drive delivers consistent and even inclusion of olives, cheese, peppers, or other ingredients combined with meat product.

- Recipe-driven, PanelView controls.

- Agitator in condiment tub prevents bridging of product.

- Pump and main 9" (230 mm) diameter feedscrew driven by 20 hp (15 kW) gearmotor.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

CORR VAC Mark III

Modified Atmosphere Packaging, also known as M.A.P. packaging equipment. Preserves, protects and extends the shelf life of your products. Whether it is individual bags, lined cases, bulk-bin, totes, Gaylords, barrel, or super-sacks, RGMTSI has a proven solution.

CORR VAC Mark III

- 100% stainless steel and FSMA, FDA, & USDA compliant. Optional 3A dairy-grade

- Always ready for wash-down as we build-to IP69 specifications assuring IP67 compliance

- Seal bars available include either 30, 54, 62, and 100-inch lengths

- Vacuum pump standard or optional liquid-ring and venturi

- Hot-bar or impulse sealing

- Bag-stretcher option to insure wrinkle free bags

- Optional two hand controls

- Flexible probes reduces damage and extends life

- A variety of language options on our simple to understand controller

- Floor mount, optional casters, or unit can hang over conveyor.

- Gas flush any product that degrades in atmosphere

- Multi-gas flush totes or super-sacks of organic products assuring inserts and larvae are asphyxiated.

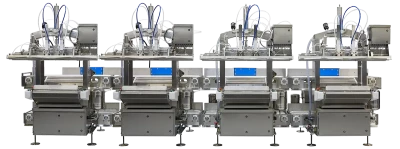

Mark III mHSP MAP Machine

Presenting the 3rd generation multi-station incorporating all of the features our customers have requested over the years while providing the safest, most sanitary and well thought out M.A.P. packaging machine of its kind on the market. Available in 2, 3, 4 or more stations allowing for unprecedented flexibility and now with higher Modified Atmosphere Packaging speeds. Each module includes its own infeed as well as outfeed belt. Start with 2 or three stations and easily add a 4th module in minutes as they interface and communicate by simply connecting a water-tight cable.

Mark III mHSP MAP Machine

- You thought there was a placeholder text here, but it was me DIO!

A200 Bin Modified Atmosphere Packaging Machine

The A-200 Bin Machine line brings the advantages of Modified Atmosphere Packaging to large and bulk items. Full pallets and bins can now be processed efficiently. Wrinkle free seals are achieved with seal bars up to 100 inches (2540mm) and automatic bag stretchers or clamps. Floating head prevents bag pullout.

A200 Bin Modified Atmosphere Packaging Machine

- You thought there was a placeholder text here, but it was me DIO!

CORR VAC MAP VAC

This Modified Atmosphere Packaging Machine has a 1355 mm (53.5-inch) seal-bar, polished, engineered not to bend or distort providing unprecedented and repeatable seal pressure. Wrinkles and gussets are no longer an issue, the MAP-Vac simply seals through them. Twin Teflon gas-flush / vacuum probes at 9.25” or 15 inch spacing opens easily and can be 100% sanitized

CORR VAC MAP VAC

- Twice the seal. Introducing a first of its kind Dual-Pinch, Dual-Seal, hot bar sealing system with cooledge technology. No other M.A.P. machine offers such a wide seal surface area.

- The Corr-Vac MAP-Vac has retractable bag stretchers for quick access for ease of use.

- The B & R model C30 TFT full-color 7” power-panel touch screen offers 4/8 program capability.

- By pressing both cycle buttons simultaneously, the operator's hands are out of the way of the closing seal bar