- Home

- Industries

- Food

- Sausage

Sausage Equipment

A sausage is a type of meat product usually made from ground meat, often pork, beef, or poultry, along with salt, spices and other flavourings. Other ingredients such as grains or breadcrumbs may be included as fillers or extenders. RGMTSI offers high-quality meat processing equipment, jerky and sausage making supplies, and food preparation tools. We focus on making your production line fast and efficient while maintaining high-quality product.

LS 600R Roboloader

All the features of the LS-600 with the added benefit of robotic product placement into packaging pockets. The high-speed picking robot has a 3kg payload. With high-quality surfaces and food-grade lubrication of the robot, it is ideal to handle soft product such as natural casing and CoEx. The LS-600R is exceptionally durable. The stainless steel open frame is able to withstand the severe sanitation procedures used in RTE environments. Furthermore, industrial cleaning methods are tolerated by the robot in accordance with IP67-69K certification. Increased capacity available with the LS-1200R model which loads up to 1200 pieces per minute.

LS 600R Roboloader

- You thought there was a placeholder text here, but it was me DIO!

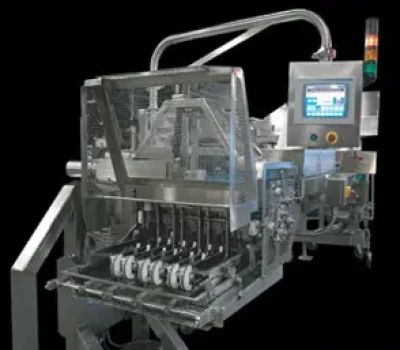

LS 640DR Roboloader

Designed for smaller producers, the LS-640-DR can load up to 600 frankfurters per minute. The entire LS-640-DR features a simple design and is easy-to-maintain. No specialized robotics training required.

LS 640DR Roboloader

- Designed for the unique needs of the food industry

- All stainless-steel construction to resist rusting.

- No painted parts to contaminate your food product.

- Rugged design to withstand intense food industry wash down & cleaning.

- Capable of carrying a 13 pound (6kg) load at full speed.

LS 840 And LS 1250 Launcher Style Loader

The Drake LS-840 and LS-1250 entry-level loaders encompass all of the hygienic design benefits of other Launcher Style loaders, but in a compact design ideal for mid-sized packaging lines. The LS-840 is capable of loading up to 800 pieces per minute, while the LS-1250 is capable of loading up to 1200 pieces per minute. Both loaders can handle a variety of products up to 200mm in length (8 inches). Designed with hygiene and safety in mind, all areas with moving parts are completely guarded. In addition, the unit can be taken apart and quickly cleaned. Both the LS-840 and LS-1250 are extremely durable. All areas of the machine are driven by AC stainless steel motors that are totally enclosed to withstand the severe sanitation procedures used in RTE environments. Multiple count and multiple layers are easily and quickly changed from one package size to another. The loader is designed to package both bulk and retail packages.

LS 840 And LS 1250 Launcher Style Loader

- You thought there was a placeholder text here, but it was me DIO!

CS 1800 Collator Style Loader

CS-1800 is our most popular and versatile collator style high speed frankfurter loader. This unit can handle skinless or skin-on, cooked and chilled frankfurters from 12 to 32mm diameters* and from 3” length (76mm) to 12” length (300mm). The model CS-1800 can load up to 1,800 pieces per minute of a 5” long (127mm) product with a 98% fill rate. All frankfurter loaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader. The collator style loader offers a unique first-in/first-out handling method minimizing recirculation of product. This unit’s intermediate conveyor inspection flights are made of rugged stainless steel, as is most of the machine, making this the toughest loader on the market.

CS 1800 Collator Style Loader

- Wave or Slimline Options available.

- A new advancement in sanitation for the CS-1800 loader is the sani-chain collator. Featuring removable flights, places that could only be cleaned infrequently can now be cleaned daily.

CSS 1800 Collator Style Loader

The CSS-1800 features our new sani-chain collator, with easy to remove collator flights. Areas of the loader that could only be cleaned infrequently can now be cleaned daily. In addition, the CSS-1800 has a lower profile than our standard CS-1800 loader, which makes it even easier for your cleaning crew to reach more areas of the machine. It can load up to 1,800 pieces per minute of a 5” long (127mm) product with a 98% fill rate. All frankfurter loaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader. The collator style loader offers a unique first-in/first-out handling method minimizing recirculation of product. For delicate product, pneumatic hinge gates are optional. The sani-chain collator is also available as a stand-alone retrofit for CS-1800 loaders.

CSS 1800 Collator Style Loader

- You thought there was a placeholder text here, but it was me DIO!

CF Style Loaders

The CF line features low to the ground, all stainless-steel centrifugal feeder technology that separate and singulate frankfurters for fast, hassle-free loading.

CF Style Loaders

- Low to the ground rotating bowls make cleaning easy.

- All CF loaders come equipped with a lifting device mounted to the side of the loader to make removal of the stainless disc ergonomic for your employees.

- All loaders are custom designed for your product & facility needs. As your requirements dictate, CF loaders can feature one or two centrifugal feeders.

- All frankfurter loaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader.

- Robotic loading head optional.

CS Bag Loader

Bag Loader can semi-automatically load exact counts of sausages into bags. This unit can bag skinless or skin-on, cooked and chilled frankfurters from 12 to 32mm diameters* and from 3” length (7mm) to 12” length (300mm).

CS Bag Loader

- The bag loader can load up to 1,500 pieces per minute of a 5” long (127mm) product with a 98% fill rate, using 3, 4, 6 or 8 manual bagging stations.

- All frankfurter loaders feature touch screen controls that allow for the easy addition of new recipes and rapid adjustment to various areas of the loader.

- All loaders offer a unique first-in/first-out handling method minimizing recirculation of product.

- This unit’s intermediate conveyor inspection flights are made of rugged stainless steel, as is most of the machine, making this the toughest loader on the market.

LS 1400 Launcher Style Loader

LS-1400 is the most sanitary launcher style high speed frankfurter loader on the market. This unit can handle skinless or skin-on, cooked and chilled and frozen frankfurters from 14 to 32mm diameters* and from 3 1/8” length (79.375mm) to 8 3/4” length (222.25mm). (*May require change of bucket conveyor, subject to final specification analysis.)

LS 1400 Launcher Style Loader

- The model LS-1400 can load up to 1400 pieces per minute of a 5” long (127mm) product with a 98% fill rate.

- All frankfurter loaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader. The Drake LS-1400 launcher style loader offers a compact footprint and a design that allows it to be stripped for cleaning in less than an hour. This unit’s launcher section utilizes sanitary food belts that easily remove for cleaning.

LS 1800 Launcher Style Loader

Launcher Style high speed Autoloaders are the most sanitary loaders on the market today. These units can handle skinless or skin-on, cooked and chilled products from 14 to 32mm in diameter* and from 3 1/8” length (79.375mm) to 8 3/4” length (222.25mm). (*May require change of bucket conveyor, subject to final specification analysis.)

LS 1800 Launcher Style Loader

- The model LS-1800 can load up to 1,800 pieces of a 5” long (127mm) product with a 98% fill rate.

- Autoloaders feature touch screen controls that allow for easy addition of new recipes and rapid adjustment to various areas of the loader.

- LS-1800 launcher style loader offers a compact footprint and a design that allows it to be stripped for cleaning in less than an hour.

- This unit’s launcher section utilizes sanitary food belts that easily remove for cleaning.

SR 400 Robot Autoloader

SR-400 open channel autoloader features an easy-to-operate robotic system to place various food products into multiple horizontal packaging configurations. The entire unit is operated by a single Allen Bradley LS-71 PLC to provide steady, reliable operating for years to come. The high-speed end of arm tooling (EOAT) robot has a 3kg payload. With high-quality materials, the EOAT is ideal to handle soft product such as natural casing and CoEx.

SR 400 Robot Autoloader

- The unit offers the hygienic design benefits of other launcher style loaders in a compact design ideal for smaller-sized packaging lines. With hygiene and safety in mind, all areas with moving parts of the SR-400 are completely guarded.

- The SR-400 loads up to 400 pieces per minute and can handle a variety of products up to 200 mm (8 inches) in length, making it ideal for packaging lines operating at 0.6 to 1 ton per hour capacity. The SR-200 model provides 200 pieces per minute capacity.

- Loads both bulk and retail packages. Multiple count and multiple layers are easily and quickly changed from one package or product to another. The model SR-400 is exceptionally durable. The stainless steel open frame and robot is able to withstand the severe sanitation procedures used in RTE environments.

- Using your existing cutter, the SR-400 can also be adapted to most conveyor-type cutting or barrel delinker.

- All autoloaders feature touch screen controls, allowing for easy addition of new recipes and rapid adjustment to various areas of the loader.