- Home

- Industries

- Food

- Seafood

Seafood Equipment

Seafood is any form of sea life regarded as food by humans, prominently including fish and shellfish. Shellfish include various species of molluscs, crustaceans, and echinoderms. RGMTSI is the leading global supplier of advanced standalone equipment and integrated systems to the fish industry. Whatever your organization's size or objectives, we have the products and expertise to help your business thrive.

PrimeMove Air Pump

Ideal for whole muscle meat and poultry applications, soups and chilies, processed foods, pet foods, whole berries, vegetables, pie fillings, wine mash, cheese curds and sauces, the Air Pump (CAP) can handle your food pumping applications without bruising or shearing. Available in various pump sizes, Air Pump can pump compressible solids up to 6" (152 mm) in diameter while preserving product integrity and increasing process yield. Perhaps you are introducing a pump into your process for the first time and have concerns about damage to product. Or maybe you are already experiencing an unacceptable amount of pump damage. In either case, the gentle flow, non-damaging Air Pump may fit your needs.

PrimeMove Air Pump

- Gentle, non-damaging product transfer.

- Air operated, positive displacement and electrically controlled.

- Various pump sizes available. Can be coupled to any custom designed stainless steel hopper to fit your application and floor plan.

- Only 2 moving parts: inlet and outlet gates.

- No motors.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

Stuffing Hoppers (CSH) are designed to integrate seamlessly into today's high volume, continuous processing lines. Direct-discharge valving systems enable CSH units to automatically receive product from upstream units. This greatly reduces or in many cases, completely eliminates human labor associated with handling and transporting of product, thus eliminating product contamination. The modular CSH system can be custom configured from one to multiple chamber units and can be equipped with numerous options to maximize the efficiency of your specific operation. Our CSH units are especially useful when incorporated into a complete emulsion/reduction line.

PrimeMove Stuffing Hopper With Stainless Positive Displacement Pump

- Each hopper utilizes an independent hydraulically driven, stainless steel, positive displacement (PD) pump.

- Bypass valves are completely eliminated and steady line pressures of 70-80 psi (4.8-5.5 bars) are maintained for exact finished product weight.

- Custom designed hoppers to fit your production requirements and floor plan.

- Quick-release coupling device between hopper throat and PD pump and easily accessible pump rotors for thorough sanitation.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

PrimeMove VSS-3 Vacuum Stuffing / Filling System

When it comes to high volume, continuous-flow, vacuum stuffing and filling applications, the Vacuum Stuffer (VSS) series stands in a performance class by itself. With the unique VSS design, improved / consistent finished product vacuum levels and high volume flow rates are ensured. The VSS utilizes dependable hydraulic power. A fully integrated heat exchanger keeps hydraulic fluid cool for dependable operation even under extended periods of heavy usage. From fine emulsions and coarse reductions, to sectioned, whole muscle mixtures, VSS brings a new level of efficiency and economy to any high volume stuffing / filling system.

PrimeMove VSS-3 Vacuum Stuffing / Filling System

- Vacuum stuffing capacity: Up to 28,000 lbs. (12,700 kg) per hour, depending on product.

- Variable speed vane pump, feedscrew and agitator are powered by a heavy-duty hydraulic drive system.

- Vacuum cover opens and closes pneumatically. For operator safety, an interlock device prevents the lid from accidental closure.

- Quick and easy vacuum loading.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

SUSPENTEC Particle Reduction System for Injection Processes

Used worldwide to process roast beef, ham, turkey breast, chicken products, steaks, fish, bacon and various other whole-muscle products, the patented SUSPENTEC process has brought significant profit building advantages to users everywhere. Hundreds of processors of fresh, cooked, refrigerated or frozen meats and seafood worldwide are using the SUSPENTEC system to add value to their products while lowering their costs of finished goods. An application-customized SUSPENTEC system inject lower cost protein materials into higher cost whole muscle products. Enhanced binding, reduced cook and chill shrink and increased slicing yields are just a few benefits realized. The heart of the SUSPENTEC process lies in its high-throughput, precise, MultiCut reduction system where the mixture recirculates through the reduction unit and mixing hopper until it becomes a homogeneous mixture of brine and ultra fine particles of meat. When exact particle size or temperature is achieved, a divert valve automatically directs suspension to feed one or two holding hoppers. An optional chiller maintains the critical suspension temperature. From the holding hopper(s), a pump delivers suspension to a standard injector. Whole muscle product is then injected with the suspension to the preset yield gain. Excess suspension from the injector is captured by a return hopper and reprocessed. The modular and compact SUSPENTEC system is adaptable to practically any plant layout.

SUSPENTEC Particle Reduction System for Injection Processes

- SUSPENTEC system consists of Mixing hopper with MultiCut reduction unit, Holding hopper(s) with optional chiller(s), Return hopper from injector, Return reduction unit (optional).

- The process involves mixing a brine solution with lower cost materials such as trimmings, rework, etc. and injecting mix into more costly whole muscle product.

- The modular SUSPENTEC system is adaptable to each unique application depending on plant layout and space considerations.

- Increased bind, reduced cook and chill shrink, increased slice yield and lower overall product cost.

- USDA accepted and CE approved. Built in conformity with AMI sanitary equipment design principles.

DuoMax

Many in the industry are in the predicament of switching equipment around constantly to setup for different products. One of these switches involves moving an inline or flat breader and switching it for a drum breader for their homestyle products. The DuoMax was designed to eliminate the need to move around equipment. It works as both a flat breader and a drum breader and easily switches between the two different modes for maximum efficiency. Inside the DuoMax is an adjustable conveyor attached to three drums. The conveyor can be put in the up position for flat breading and moved to the down position for homestyle products. The drums are easily removable for sanitation and the hood can be disassembled for ease of maintenance. The entire system is controlled by an HMI screen using a recipe based program. If you desire to make better use of the time normally used to switch out equipment, contact us about the DuoMax today!

DuoMax

- You thought there was a placeholder text here, but it was me DIO!

VCS Batter Mixer

Batter Mixer

VCS Batter Mixer

- Ultrasonic in-line viscometer controlling a wide range of viscosities with extremely tight tolerances. No calibration required. CIP capable

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Fully automated controls using an AB PLC & color touchscreen for 100% automated control of batter mixing and monitoring

- All stainless steel viscosity pump and motor with direct drive

- Stainless steel 2 HP mixer

- Sanitary stainless steel water piping

- Stainless steel feed pump and motor with direct drive are controlled using variable frequency drives for speed and flow control

- Ergonomically designed low profile batter hopper available in standard 34” load height with 100 lb. capacity

- Can produce batter with tolerances of less than one-third of a cup second, which equals 5-6 centipoise

- Stainless sanitary piping

- Out-of-spec alarm system monitoring temperature and motor overloads

- Perforated parts basket for all sanitary and pump parts

- High efficiency, stainless steel mix tank w/cooling jacket on exterior of side and bottom of tank (180 PSI A.S.M.E. Certified/Stamped)

Fillet Splitter

As a way to greatly reduce labor for plants that are natural falling or selling line run fillets, RGMTSI has developed the Fillet Splitter. Our Fillet Splitter utilizes high pressure water to split boneless skinless butterfly breasts into fillets at rates of up to 100 butterflies per minute per lane. Since all our equipment is custom built to fit specific needs, customers can select their desired infeed and outfeed lengths, number of lanes of production, and height off the floor. As with all our equipment, the Fillet Splitter utilizes food grade stainless steel, plastics and belting. The Fillet Splitter comes fully equipped with door guards, E-Stops, and a relief valve to ensure the highest level of safety. If your customer has strict requirements on keel removal, there is no need for additional labor, we can develop your Fillet Splitter to remove keel ribbon and provide your customers with the outstanding product they are expecting. There are endless possibilities with the Fillet Splitter, so call your Sales Representative today to discuss options you may have in mind.

Fillet Splitter

- You thought there was a placeholder text here, but it was me DIO!

Marination System

As the critical starting point for your further processing lines, consistent marination is essential for your success. RGMTSI is pleased to offer a fully integrated brine marination mixing system. By utilizing high shear mixing options, automatic ingredient loading, recipe controls,heat exchangers, and temperature controls, RGMTSI's Master Marination System is the fully integrated solution for all you marination mixing needs.

Marination System

- You thought there was a placeholder text here, but it was me DIO!

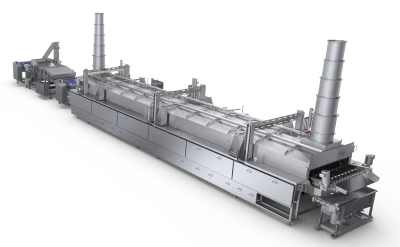

Batter, Breading, And Frying Lines

RGMTSI offers fully integrated Batter, Breading, and Frying lines. Each machine in the line can be controlled from a single HMI Panel, giving one operator complete control over several pieces of equipment. Lines can be customized to fit your processing needs by utilizing our batter and equipment in any order you choose.

Batter, Breading, And Frying Lines

- You thought there was a placeholder text here, but it was me DIO!

TCS Batter Mixer

Batter Mixer

TCS Batter Mixer

- An ALL electric automated tempura batch mixing system with very precise mix accuracy and temperature control

- Standards & guidelines to Food Safety & USDA requirements

- Construction is all stainless steel frame and assembled using US standard food safety components

- Capable of producing up to 660 gallons of tempura per hour or as little as 25 gallon per hour. The TCS can mix and pump a batch of tempura in 5 minutes or less.

- High efficiency 50 or 70 gallon insulated tanks

- Adjustable batch size that is 100% programmable

- All stainless steel Unibloc PD feed pump with variable speed

- All stainless steel direct driven mixer with precise speed control of a VFD

- All stainless steel water and sanitary piping

- All stainless steel jacketed & insulated mix tank with jackets on side & bottom of tank (180 psi ASME Certified & Stamped)

- Ergonomically designed low profile hopper with 150lb capacity

- Self-diagnostics for alarms, temperatures and motor O.L.

- Perforated parts basket for all sanitary and pump parts during disassembly