- Home

- Industries

- Food

- Seafood

Seafood Equipment

Seafood is any form of sea life regarded as food by humans, prominently including fish and shellfish. Shellfish include various species of molluscs, crustaceans, and echinoderms. RGMTSI is the leading global supplier of advanced standalone equipment and integrated systems to the fish industry. Whatever your organization's size or objectives, we have the products and expertise to help your business thrive.

AllroundSystem ARQ

Optimal air circulation and air volume ensure a uniform product. Operating temperatures are reached quickly and maintained at a constant level thanks to efficient system isolation.

AllroundSystem ARQ

- Consistent product results: Horizontal air circulation, suction and the adaptation of the air quantity to products guarantee constant and reproducible production results.

- High loading capacity: Thanks to the horizontal air circulation, all products, such as baked sausage meat in various moulds, with minimum vertical clearances (min. 5 cm above the product) can be loaded onto the oven trolley. The systems therefore offer a maximum loading and product capacity.

- Efficiency: The system’s energy supply is selected so that the set values can be rapidly achieved. The cabinet insulation maintains the operating temperature over a long period. Short process times thanks to exceptionally high quantities of circulating air lead to a lower weight loss and therefore to a higher production capacity.

Intensive cooling system IUL

Fast and controlled cooling of products reduces unnecessary weight loss and increases production output. Individually tailored solutions can be developed for both larger industrial or smaller trade companies.

Intensive cooling system IUL

- Improved product quality: The shelf life of products is extended as quickly cooled and fresh goods are packed. Controlled cooling of products reduces unnecessary weight loss and increases production output.

- Efficiency: Shorter process times are achieved by pre-cooling with a water shower and the integrated misting system. Savings on cooling costs as the energy of outside air is used to its full potential.

- Minimum space requirement: Individually tailored solutions can be developed for both larger industrial or smaller trade companies thanks to the system’s exceedingly small width and height dimensions. Building investment costs are reduced considerably.

ProfitLine PUR

Among other things, this ProfitLine offers the possibility of pre-cooling products with a water shower, which makes work processes effective, fast and energy-saving.

ProfitLine PUR

- Improved product quality: The shelf life of products is extended as quickly cooled and fresh goods are packed. Controlled cooling of products reduces unnecessary weight loss and increases production output.

- Efficiency: Shorter process times are achieved by pre-cooling with a water shower and the integrated misting system. Savings on cooling costs as the energy of outside air is used to its full potential.

- Designed for industry: Cooling capacity adjustable to product

CORR VAC Mark III

Modified Atmosphere Packaging, also known as M.A.P. packaging equipment. Preserves, protects and extends the shelf life of your products. Whether it is individual bags, lined cases, bulk-bin, totes, Gaylords, barrel, or super-sacks, RGMTSI has a proven solution.

CORR VAC Mark III

- 100% stainless steel and FSMA, FDA, & USDA compliant. Optional 3A dairy-grade

- Always ready for wash-down as we build-to IP69 specifications assuring IP67 compliance

- Seal bars available include either 30, 54, 62, and 100-inch lengths

- Vacuum pump standard or optional liquid-ring and venturi

- Hot-bar or impulse sealing

- Bag-stretcher option to insure wrinkle free bags

- Optional two hand controls

- Flexible probes reduces damage and extends life

- A variety of language options on our simple to understand controller

- Floor mount, optional casters, or unit can hang over conveyor.

- Gas flush any product that degrades in atmosphere

- Multi-gas flush totes or super-sacks of organic products assuring inserts and larvae are asphyxiated.

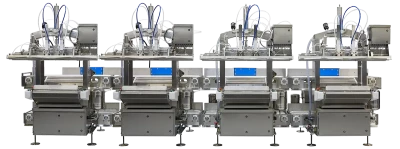

Mark III mHSP MAP Machine

Presenting the 3rd generation multi-station incorporating all of the features our customers have requested over the years while providing the safest, most sanitary and well thought out M.A.P. packaging machine of its kind on the market. Available in 2, 3, 4 or more stations allowing for unprecedented flexibility and now with higher Modified Atmosphere Packaging speeds. Each module includes its own infeed as well as outfeed belt. Start with 2 or three stations and easily add a 4th module in minutes as they interface and communicate by simply connecting a water-tight cable.

Mark III mHSP MAP Machine

- You thought there was a placeholder text here, but it was me DIO!

A200 Bin Modified Atmosphere Packaging Machine

The A-200 Bin Machine line brings the advantages of Modified Atmosphere Packaging to large and bulk items. Full pallets and bins can now be processed efficiently. Wrinkle free seals are achieved with seal bars up to 100 inches (2540mm) and automatic bag stretchers or clamps. Floating head prevents bag pullout.

A200 Bin Modified Atmosphere Packaging Machine

- You thought there was a placeholder text here, but it was me DIO!

CORR VAC MAP VAC

This Modified Atmosphere Packaging Machine has a 1355 mm (53.5-inch) seal-bar, polished, engineered not to bend or distort providing unprecedented and repeatable seal pressure. Wrinkles and gussets are no longer an issue, the MAP-Vac simply seals through them. Twin Teflon gas-flush / vacuum probes at 9.25” or 15 inch spacing opens easily and can be 100% sanitized

CORR VAC MAP VAC

- Twice the seal. Introducing a first of its kind Dual-Pinch, Dual-Seal, hot bar sealing system with cooledge technology. No other M.A.P. machine offers such a wide seal surface area.

- The Corr-Vac MAP-Vac has retractable bag stretchers for quick access for ease of use.

- The B & R model C30 TFT full-color 7” power-panel touch screen offers 4/8 program capability.

- By pressing both cycle buttons simultaneously, the operator's hands are out of the way of the closing seal bar

SC Spiral Cooler

The Spiral Cooler (SC) consists of a spiral arrangement built inside an isolated enclosure. The internal air is continuously cooled and circulated horizontally over the product. The Spiral Cooler is ideal for food applications where a fast and uniform cooling is required.

SC Spiral Cooler

- Belt width up to 1500 mm

- Single drum or twin drum spiral

- Steel or plastic spiral belt

- Stacking or non-stacking spiral belt

- Including heat exchanger and air fans

- Horizontal airflow for quick cooling and reduced product dehydration

- Maximum utilization of the spiral belt, as no air has to pass through the belt

- In-feed and out-feed in the same pressure zone

- No need for floor heating

- Multiple drive motors

- Recipe-controlled for easy operation

- Flexible design with multiple layout options

- Manufactured in stainless steel with open profiles for easier cleaning

SSSF Single Stacking Spiral Freezer

The resource-saving Single Stacking Spiral Freezer (SSSF), with its unique belt-stacking system, is presumably the most effective spiral freezer on the market when it comes to capacity and energy consumption. The unique belt design makes the SingleStacker highly suitable for freezing of convenience products such as chicken nuggets or burger patties.

SSSF Single Stacking Spiral Freezer

- Resource-saving spiral freezer with out to 30% savings on power consumption

- No risk of product jam

- Belt width up to 965 mm

- Product height up to max. 100 mm

- Steel or plastic spiral belt

- Optional: Sequential defrosting of evaporators

- Less belt supports equals less cleaning

- Horizontal airflow for quick freezing and reduced product dehydration

- Maximum utilization of the spiral belt, as no air has to pass through the belt

- In-feed and out-feed in the same pressure zone

- No need for floor heating

- Multiple drive motors

- Recipe-controlled for easy operation

- Flexible design with multiple layout options

- Manufactured in stainless steel with open profiles for easier cleaning

SDSF Single Drum Spiral Freezer

Designed for medium-large capacity processing lines with belt width up to 1500 mm, the Single Drum Spiral Freezer (SDSF) is suitable for almost any processing line. Extra strong belt supports makes it possible to carry heavy products demanding a long retention time. The spiral freezer is the most flexible spiral solution and can be adapted to fit almost any processing line.

SDSF Single Drum Spiral Freezer

- Belt width up to 1500 mm

- Product height as per request

- Steel or plastic spiral belt

- Non-stacking spiral belt for heavy product load

- Optional: Sequential defrosting of evaporators

- Can be adapted to suit almost any processing line

- Capable of running with heavy products (high belt load)

- Horizontal airflow for quick freezing and reduced product dehydration

- Maximum utilization of the spiral belt, as no air has to pass through the belt

- In-feed and out-feed in the same pressure zone

- No need for floor heating

- Multiple drive motors

- Recipe-controlled for easy operation

- Flexible design with multiple layout options

- Manufactured in stainless steel with open profiles for easier cleaning