- Home

- Industries

- Food

- Vegetable

Vegetable Equipment

Vegetables are parts of plants that are consumed by humans or other animals as food. The original meaning is still commonly used and is applied to plants collectively to refer to all edible plant matter, including the flowers, fruits, stems, leaves, roots, and seeds. Our fruit and vegetable food processing solutions are designed to handle the most delicate products while maintaining product integrity. Whether you need our vacuum pumping systems for handling soups and fillings or need to cook and grill fresh veggies, we have a wide array of equipment to suit your specific application. Collaborate with our highly experienced team of food processing technologists to craft new products or test new processing methods for your value-added fruits and vegetables.

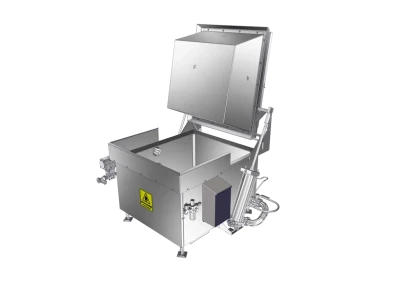

Cooking VAT Chaudix

The Chaudix™ cooking system has been designed to optimize small batch cooking and blanching for the food industry. Its polyvalent, ergonomically and easy to use design provides a cost efficient and food safe solution for Central kitchens, Food service, Food processing.

Cooking VAT Chaudix

- The Chaudix system is an integrated water immersion cooking unit solution with a pneumatic unloading system for the cooking basket. It can be equipped with the Balix system for loading products with European 200 L trolley.

- Ergonomically designed

- Food safety

- Insulated tank with steam proof lid

- Water temperature and level regulation

Kitchenix

The Kitchenix is a fully automated advanced water cook & chill system for Sous Vide cooking technology. It has been specially designed to meet small and medium production needs like Restaurants, Ghost and satellite kitchens and Caterers.

Kitchenix

- The Kitchenix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Kitchenix to suit customer's need

- The Kitchenix system includes Thermix Connect web based controls and mobile app which allow users to monitor overnight cooking without having physical presence on the kitchen.

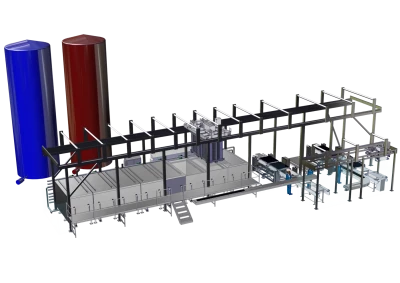

Thermix Sous Vide

Thermix Sous Vide System is a fully automated, advanced water cook & chill process especially design for Sous Vide cooking technology. Industrial food processors can consistently produce guaranteed safe food product of the best quality at highest yields. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope.

Thermix Sous Vide

- Thermix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Thermix to suit customer's need

- The automated Thermix Sous Vide System works continuously at a steady pace of 0.5 to 5 tons per hour with various levels of automation delivering a constant flow of superior-quality products with minimal human labor involvement. The system streamlined design results in exceptionally low maintenance costs

Pico Thermix

The Pico-Thermix is by far the smallest unit that we developed with our industrial customers to perform R&D tests with the same level of expertise that the Thermix solution provides. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope. Sous Vide offers the longest shelf life for natural and tasty products without preservatives, resulting in benefits for all users. The Pico-Thermix system flexible, unique design and controls allows processing a variety of products. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

Pico Thermix

- Undisputed quality

- Food safety & traceability

- Integrated heating & chilling

- Best consistency & clean label

- Batches of 4-6kg | 11lbs

- Advanced recipe controls

- Complete traceability plotting

- Remote web-based monitoring Thermix™ Connect

- Suited for 220/50Hz and 220V/60Hz

- No plant utility required. Works perfect at home.

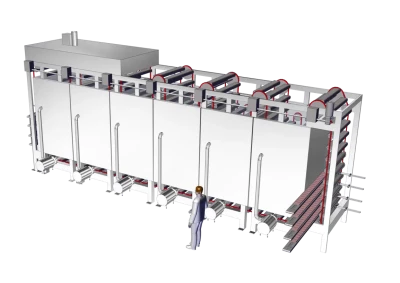

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

CORR VAC Mark III

Modified Atmosphere Packaging, also known as M.A.P. packaging equipment. Preserves, protects and extends the shelf life of your products. Whether it is individual bags, lined cases, bulk-bin, totes, Gaylords, barrel, or super-sacks, RGMTSI has a proven solution.

CORR VAC Mark III

- 100% stainless steel and FSMA, FDA, & USDA compliant. Optional 3A dairy-grade

- Always ready for wash-down as we build-to IP69 specifications assuring IP67 compliance

- Seal bars available include either 30, 54, 62, and 100-inch lengths

- Vacuum pump standard or optional liquid-ring and venturi

- Hot-bar or impulse sealing

- Bag-stretcher option to insure wrinkle free bags

- Optional two hand controls

- Flexible probes reduces damage and extends life

- A variety of language options on our simple to understand controller

- Floor mount, optional casters, or unit can hang over conveyor.

- Gas flush any product that degrades in atmosphere

- Multi-gas flush totes or super-sacks of organic products assuring inserts and larvae are asphyxiated.

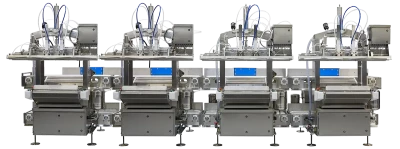

Mark III mHSP MAP Machine

Presenting the 3rd generation multi-station incorporating all of the features our customers have requested over the years while providing the safest, most sanitary and well thought out M.A.P. packaging machine of its kind on the market. Available in 2, 3, 4 or more stations allowing for unprecedented flexibility and now with higher Modified Atmosphere Packaging speeds. Each module includes its own infeed as well as outfeed belt. Start with 2 or three stations and easily add a 4th module in minutes as they interface and communicate by simply connecting a water-tight cable.

Mark III mHSP MAP Machine

- You thought there was a placeholder text here, but it was me DIO!

A200 Bin Modified Atmosphere Packaging Machine

The A-200 Bin Machine line brings the advantages of Modified Atmosphere Packaging to large and bulk items. Full pallets and bins can now be processed efficiently. Wrinkle free seals are achieved with seal bars up to 100 inches (2540mm) and automatic bag stretchers or clamps. Floating head prevents bag pullout.

A200 Bin Modified Atmosphere Packaging Machine

- You thought there was a placeholder text here, but it was me DIO!

CORR VAC MAP VAC

This Modified Atmosphere Packaging Machine has a 1355 mm (53.5-inch) seal-bar, polished, engineered not to bend or distort providing unprecedented and repeatable seal pressure. Wrinkles and gussets are no longer an issue, the MAP-Vac simply seals through them. Twin Teflon gas-flush / vacuum probes at 9.25” or 15 inch spacing opens easily and can be 100% sanitized

CORR VAC MAP VAC

- Twice the seal. Introducing a first of its kind Dual-Pinch, Dual-Seal, hot bar sealing system with cooledge technology. No other M.A.P. machine offers such a wide seal surface area.

- The Corr-Vac MAP-Vac has retractable bag stretchers for quick access for ease of use.

- The B & R model C30 TFT full-color 7” power-panel touch screen offers 4/8 program capability.

- By pressing both cycle buttons simultaneously, the operator's hands are out of the way of the closing seal bar

SBF Belt Freezer

The Belt Freezer (SBF) is highly suitable for freezing of diced meat products and other similar small products. Upward vertical airflow in combination with belt tumblers creates a gentle turbulence in the product layer, ensuring a high-quality IQF product. In-feed and out-feed positioned at floor level of the Scanico Belt Freezer allows for an easy transfer from/to further processing lines.

SBF Belt Freezer

- Belt width up to 1400 mm

- One or more belts in different widths

- Flexible design, with standard extendable modules

- Easily adjustable degree of turbulence

- Heavy-duty drive motor

- No need for floor heating

- Recipe-controlled for easy operation

- Manufactured in stainless steel with open profiles for easier cleaning