- Home

- Industries

- Food

- Whole Muscle

Whole Muscle Equipment

Whole-muscle meat is raw material from animals that has not been ground, chopped or cut other than to develop a particular shape. With our modular and powerful meat blending and mixer, your meat production process will become a breeze. No more stops at each step, only but continous release of high quality produced meat.

MP800 Advantage and EXTRA 26 inch Formers

MP800 ADVANTAGE former and MP800 EXTRA former with optional Patented Multi-Flow system for the highest production requirements. The former can process a wide variety of proteins and vegetables, and offers several fill options: Standard Fill for ground or emulsified products, Vertical Fill for larger pieces and whole muscle, Portion Fill which is a variation of Vertical Fill and Soft Fill for ground product.

MP800 Advantage and EXTRA 26 inch Formers

- Capabilities up to 110 SPM

- Production rate of up to 9,000#/hr

- 9", 10", and 13" stroke lengths

- Heavy duty Winsmith connection rod, KO drive, and feed screw system

- Stainless steel package standard

- NEMA 4X style door package

- Stainless steel hydraulic reservoir standard

- Stainless steel upper right-angle drive

- Touchscreen with PLC controls

- Stainless steel hydraulic reservoir standard

MP800 Servo 26 inch Former

MP800 SERVO former with optional Patented Multi-Flow system for the highest production requirements. The former can process a wide variety of proteins and vegetables, and offers several fill options: Standard Fill for ground or emulsified products, Vertical Fill for larger pieces and whole muscle, Portion Fill which is a variation of Vertical Fill and Soft Fill for ground product.

MP800 Servo 26 inch Former

- Capabilities up to 110 SPM

- Production rate of up to 9,000#/hr

- 9", 10", and 13" stroke lengths

- Touchscreen with PLC controls

- Super Heavy-duty parts throughout

- Servo Plunger Actuators

- Servo Tube Valve Drive

- Servo Knock Out Drive

- Servo Mold Plate

- Product Feed Conveyor Features integrated driver roller

Marination System

As the critical starting point for your further processing lines, consistent marination is essential for your success. RGMTSI is pleased to offer a fully integrated brine marination mixing system. By utilizing high shear mixing options, automatic ingredient loading, recipe controls,heat exchangers, and temperature controls, RGMTSI's Master Marination System is the fully integrated solution for all you marination mixing needs.

Marination System

- You thought there was a placeholder text here, but it was me DIO!

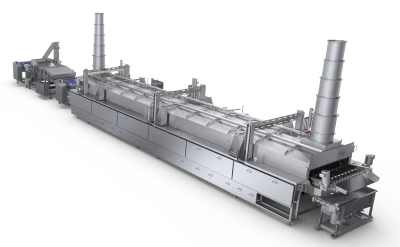

Batter, Breading, And Frying Lines

RGMTSI offers fully integrated Batter, Breading, and Frying lines. Each machine in the line can be controlled from a single HMI Panel, giving one operator complete control over several pieces of equipment. Lines can be customized to fit your processing needs by utilizing our batter and equipment in any order you choose.

Batter, Breading, And Frying Lines

- You thought there was a placeholder text here, but it was me DIO!

DuoMax

Many in the industry are in the predicament of switching equipment around constantly to setup for different products. One of these switches involves moving an inline or flat breader and switching it for a drum breader for their homestyle products. The DuoMax was designed to eliminate the need to move around equipment. It works as both a flat breader and a drum breader and easily switches between the two different modes for maximum efficiency. Inside the DuoMax is an adjustable conveyor attached to three drums. The conveyor can be put in the up position for flat breading and moved to the down position for homestyle products. The drums are easily removable for sanitation and the hood can be disassembled for ease of maintenance. The entire system is controlled by an HMI screen using a recipe based program. If you desire to make better use of the time normally used to switch out equipment, contact us about the DuoMax today!

DuoMax

- You thought there was a placeholder text here, but it was me DIO!

VCS Batter Mixer

Batter Mixer

VCS Batter Mixer

- Ultrasonic in-line viscometer controlling a wide range of viscosities with extremely tight tolerances. No calibration required. CIP capable

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Fully automated controls using an AB PLC & color touchscreen for 100% automated control of batter mixing and monitoring

- All stainless steel viscosity pump and motor with direct drive

- Stainless steel 2 HP mixer

- Sanitary stainless steel water piping

- Stainless steel feed pump and motor with direct drive are controlled using variable frequency drives for speed and flow control

- Ergonomically designed low profile batter hopper available in standard 34” load height with 100 lb. capacity

- Can produce batter with tolerances of less than one-third of a cup second, which equals 5-6 centipoise

- Stainless sanitary piping

- Out-of-spec alarm system monitoring temperature and motor overloads

- Perforated parts basket for all sanitary and pump parts

- High efficiency, stainless steel mix tank w/cooling jacket on exterior of side and bottom of tank (180 PSI A.S.M.E. Certified/Stamped)

TCS Batter Mixer

Batter Mixer

TCS Batter Mixer

- An ALL electric automated tempura batch mixing system with very precise mix accuracy and temperature control

- Standards & guidelines to Food Safety & USDA requirements

- Construction is all stainless steel frame and assembled using US standard food safety components

- Capable of producing up to 660 gallons of tempura per hour or as little as 25 gallon per hour. The TCS can mix and pump a batch of tempura in 5 minutes or less.

- High efficiency 50 or 70 gallon insulated tanks

- Adjustable batch size that is 100% programmable

- All stainless steel Unibloc PD feed pump with variable speed

- All stainless steel direct driven mixer with precise speed control of a VFD

- All stainless steel water and sanitary piping

- All stainless steel jacketed & insulated mix tank with jackets on side & bottom of tank (180 psi ASME Certified & Stamped)

- Ergonomically designed low profile hopper with 150lb capacity

- Self-diagnostics for alarms, temperatures and motor O.L.

- Perforated parts basket for all sanitary and pump parts during disassembly

MP115 Flat Breader

Flat Breader

MP115 Flat Breader

- Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

- Flour coating configuration

- Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

- MP rotating top flow breading distribution system

- Standard casters with stainless steel frame and Phenolic Wheels

- Rotating belt vibrator

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

- Positive cam/lock on all access doors

- Lift cylinder on discharge chute, hopper and covers

- Adjustment/support for discharge of batter applicator

- Belt tension adjustment for hopper/main belt

- Stand-off bearings for maximum sanitary design

- Engineered for safety, user friendliness and optimum uptime

- Operator controls ergonomically designed

- Designed for 40” and 52” usable belt width

MP116 J Crumb Breader

Crumb Breader

MP116 J Crumb Breader

- Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

- Flour coating configuration for free flow and Japanese crumb coatings

- Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

- Rotating top flow breading distribution system

- Standard casters with stainless steel frame and Phenolic Wheels

- Rotating belt vibrator

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

- Positive cam/lock on all access doors

- Lift cylinder on discharge chute, hopper and covers

- Adjustment/support for discharge of batter applicator

- Belt tension adjustment for hopper/main belt

- Stand-off bearings for maximum sanitary design

- Engineered for safety, user friendliness and optimum uptime

- Operator controls ergonomically designed

- 40” usable belt width

MP120 Drum Breader

Drum Breader

MP120 Drum Breader

- All stainless steel drum provides unmatched durability and maximum production capability

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Heavy-duty drum drive support system provides positive drum drive without slipping

- Exclusive MP direct auger transfer system helps eliminate breading jamming and provides efficient transfer with less breading in machine

- Extended vertical screw housing provides more efficient breading transfer into drum without vibrators

- Includes automatic “crumb” removal system and allows precise removal of moist crumbs from flour

- Standard right hand controls, option for left hand

- One piece aluminum hydraulic manifold with stainless steel hydraulic flow control valves provides precise motor speed control

- Durable, non-rusting valves

- 10-60 FPM variable speed hydraulic drives with plated motors

- Quick disconnect couplings for easy motor change out

- Separate variable speed direct drive augers eliminates chains, sprockets and gear boxes and provides precise individual speed control

- “gull wing” door system with lift cylinders allows complete access to machine for sanitation and maintenance

- Hood provides fully enclosed drum and drive system and reduces airborne dust

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product