- Home

- Industries

- Pharmaceutical

- Capsule

Capsule Equipment

A capsule is a solid dosage form in which the drug is enclosed in a hard or soft soluble container, usually of a form of gelatin. RGMTSI provides a wide variety of Capsule Filling Machines, Manual Capsule Fillers, Capsule Polishers and Vacuums and More. We got the most ideal capsule filling equipment for pharmaceutical and health food industry.

BP 150 Blister Packing Machine

BP 150 Blister Packing Machine is a robust and GMP compliant machine featuring a modular and compact concept. It is a small size machine that optimizes blister packing process in a limited working space. The flexible design of SaintyCo BP 150 Blister Packing Machine ensures easy part changeover and adjustments. Depending on Blister packing needs, it is easier to incorporate pre-cutting, extended feeding area, printing, automatic feeder and inspection systems. BP 150 Blister Packing Machine is one of the main cold forming blister packaging machines for an efficient tablet and capsule packaging. With a robust PLC control system and touchscreen HMI, it’s easier to configure blister packing processes with a precise drive and feeding control. Also, it is easier to modify the SaintyCo BP 150 Blister Packing Machine Alu/PVC thermoforming process.

BP 150 Blister Packing Machine

- Speed: Alu/PVC up to 50cycles/min; Alu/Alu up to 25cycles/min

- Dimensions: 2500*580*1638mm

- Weight: 620kg

BP 180 Automatic Blister Packing Machine

The ability to form PVC, PVC/PVDC, PVC/OCLAR, PP and ALU/ALU makes BP 180 Automatic Blister Packing Machine cutting-edge equipment in the industry. With an easy part changeover, perfect synchronization and accurate speed regulation, BP 180 Automatic Blister Packing Machine meets the dynamic needs in the blister packaging process. Its plate-type mold and positive pressure forming makes perfect cavities for tablet or capsules blister packaging. Automatic feeding system, alarm and stop functionality of BP 180 Automatic Blister Packing Machine, guarantee a high degree of efficiency and safety. The dust handling mechanism, ability to reduce energy loss through registering machine heating and general feeder ensures a perfect blister packaging process. For an optimal packaging solution, this blister pack sealing machine is easy to operate and maintain, besides having a compact structure.

BP 180 Automatic Blister Packing Machine

- Speed: Alu/PVC up to 50cycles/min; Alu/Alu up to 30cycles/min

- Dimensions: 3200*660*1500mm

- Weight: 680kg

BP 260 Tablet and Capsule Blister Packing Machine

For moderate blister packaging process, BP 260 Tablet and Capsule Blister Packing Machine uses PVC, PVC/PVDC, PVC/ACLAR, PP or ALU/ALU. The flexible, robust, compact and cGMP compliant design optimizes blister packaging, while allowing for easy part changeover. For precise bister packaging, BP 260 Tablet and Capsule Blister Packing Machine features a servo motor system, photoelectric indexing control, temperature sensor and vision checking systems. With a specially designed plate heating system and forming mechanism, this tablet blister packing machine meets the blister packaging needs of nearly all materials. It has a robust construction, double roll system and either universal or dedicated feeders. To ensure safety, BP 260 Tablet and Capsule Blister Packing Machine has interlocked doors in all processing stations.

BP 260 Tablet and Capsule Blister Packing Machine

- Output: Max 200 blister/min

- Speed: Alu/PVC 20 – 50cyles/min; Alu/Alu 15 – 30cycles/min

- Dimensions4200*650*1700mm

- Weight: 1500kg

Capsule and Tablet Blister Cartoning Line

Capsule and Tablet Blister Cartoning Line is a new generation of blister packaging equipment with flexible and modular design. Whether in Alu/PVC or Alu/Alu blister packaging, it allows for easy integration of strapping, weighing and carton packer machines. With a robust and sturdy structure, capsule and tablet blister cartoning line comes with a PLC control system alongside a touchscreen HMI. For accuracy and consistency, Capsule and Tablet Blister Cartoning Line has camera detection with safety cover for moving parts. It has lack of material detection system with an optional HAPA aluminum foil printer. This is a blister packaging product line that meets the dynamic needs in pharmaceutical and consumer products blister packing processes.

Capsule and Tablet Blister Cartoning Line

- Production: Up to 100cartons/min

- Carton size: 60-230*20-140*18-80 mm

- Weight: 5000kg

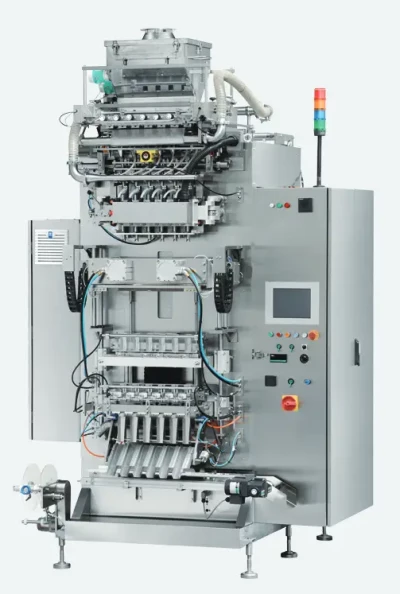

Stick Type Automatic Multi Lane Packaging Machine

Stick Type Automatic Multi Lane Packaging Machine is mainly used for stick type packaging. This packaging machine can be used for food, pharmaceutical and chemical industries. It can also be customized to accomodate 6, 8 or even 10 lanes according to customer's requirements about bag size and filling capacity which greatly improves production output. The packaging machine operation is user friendly, sachet length and production time can be adjusted just by inputiing data. Configuration settings can be saved into templates and can be swapped. This makes Stick Type Automatic Multi Lane Packaging Machine the ultimate packaging machine for your stick type packaging needs.

Stick Type Automatic Multi Lane Packaging Machine

- Built-in safety features

- No operation without compressed air

- Emergency stop control

- Overload protection feature

- Safety door

- Working capacity: 20-70 pcs/min/lane

Granule High Speed Multi Lane Packaging Machine

Granule High Speed Multi Lane Packaging Machine is mainly used for packaging granule. Elegant sachets could be produced by this high speed packaging machine by hot sealing with rollers and 4 side sealing. With high packaging efficiency, application and multi-lane handling, the Granule High Speed Multi Lane Packaging Machine can realzie high speed packaging for your production line. Granule High Speed Multi Lane Packaging Machine can produce 30-50 bags/min/lane depending on the product's volume, size and number of lanes. It can work up to 2-8 lanes.

Granule High Speed Multi Lane Packaging Machine

- Packing lanes: 2-8 lanes

- Working capacity: 30-50 bags/min/lane

Premade Pouch Fully Automatic Packaging Machine

Premade Pouch Fully Automatic Packaging Machine is suitable for the ready-made pouches packaging used for liquids, powders, granules, sauces etc. It can work with different bag variations, which can open up possibilities to different pouch / bag appearance and design from sthe standard stand-up pouches, zipper bags, accordion pockets to free shape bags. This in turn meets the demands of product variety while maintaining high speed production.

Premade Pouch Fully Automatic Packaging Machine

- Uses constant heat sealing

- Uses press bar cooling

- Recommended bag pattern: premade pouch, laminated film

- Speed: 20-50 pcs/min depending on the fluidness of products

- Available in single or double bag operation

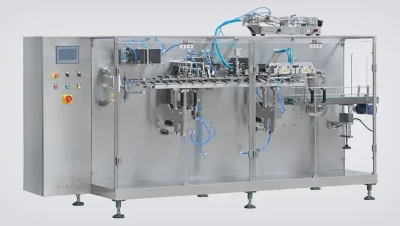

Horizontal Premade Pouch Fully Automatic Packaging Machine

Premade Pouch Fully Automatic Packaging Machine is suitable for the ready-made pouches packaging used for liquids, powders, granules, sauces etc. It can work with different bag variations, which can open up possibilities to different pouch / bag appearance and design from sthe standard stand-up pouches, zipper bags, accordion pockets to free shape bags. This in turn meets the demands of product variety while maintaining high speed production.

Horizontal Premade Pouch Fully Automatic Packaging Machine

- Recommended bag pattern: premade pouch, laminated film

- Speed: 20-70 pcs/min depending on the fluidness of products

- Available in single or double bag operation