- Home

- Industries

- Slaughter Line

- Poultry

Poultry Equipment

Poultry are domesticated birds kept by humans for their eggs, their meat or their feathers. These birds are most typically members of the superorder Galloanserae, especially the order Galliformes. RGMTSI offers solutions and services for processing of all usual types of poultry, all possible stages in the process and at any required production capacity. Besides broiler processing, we also specialize in technology and systems for processing turkeys, ducks and other breeds such as layers and parent stock. Our approach focuses on accomplishing the most value adding, tailor made production facilities.

MP116 J Crumb Breader

Crumb Breader

MP116 J Crumb Breader

- Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

- Flour coating configuration for free flow and Japanese crumb coatings

- Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

- Rotating top flow breading distribution system

- Standard casters with stainless steel frame and Phenolic Wheels

- Rotating belt vibrator

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

- Positive cam/lock on all access doors

- Lift cylinder on discharge chute, hopper and covers

- Adjustment/support for discharge of batter applicator

- Belt tension adjustment for hopper/main belt

- Stand-off bearings for maximum sanitary design

- Engineered for safety, user friendliness and optimum uptime

- Operator controls ergonomically designed

- 40” usable belt width

MP120 Drum Breader

Drum Breader

MP120 Drum Breader

- All stainless steel drum provides unmatched durability and maximum production capability

- Construction is all stainless steel frame with US standard fasteners, bearings, sprockets, belting and shafts with sanitary open frame design

- Heavy-duty drum drive support system provides positive drum drive without slipping

- Exclusive MP direct auger transfer system helps eliminate breading jamming and provides efficient transfer with less breading in machine

- Extended vertical screw housing provides more efficient breading transfer into drum without vibrators

- Includes automatic “crumb” removal system and allows precise removal of moist crumbs from flour

- Standard right hand controls, option for left hand

- One piece aluminum hydraulic manifold with stainless steel hydraulic flow control valves provides precise motor speed control

- Durable, non-rusting valves

- 10-60 FPM variable speed hydraulic drives with plated motors

- Quick disconnect couplings for easy motor change out

- Separate variable speed direct drive augers eliminates chains, sprockets and gear boxes and provides precise individual speed control

- “gull wing” door system with lift cylinders allows complete access to machine for sanitation and maintenance

- Hood provides fully enclosed drum and drive system and reduces airborne dust

- 150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

MP900 Advantage Frying System

The ADVANTAGE Frying System with state-of-the-art thermal heating leads the industry with technology that improves operating characteristics and costs of frying quality foods - the most efficient heat exchange process in the industry. After several years in development, we’ve designed and manufactured the industry’s most efficient heat exchange process. Our heat exchanger features the ADVANTAGE HelyX insert that redirects the flow of thermal fluid into a helical path, delivering balanced heat side-to-side and infeed to discharge.

MP900 Advantage Frying System

- Available in 40” and 52” widths and 25', 30', and 35' lengths

- High capacity

- High efficiency

- Fast heat recovery and control

- Low cooking oil volume

- Quick clean up time

- Low operating costs

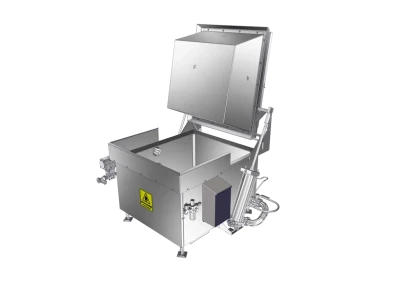

Cooking VAT Chaudix

The Chaudix™ cooking system has been designed to optimize small batch cooking and blanching for the food industry. Its polyvalent, ergonomically and easy to use design provides a cost efficient and food safe solution for Central kitchens, Food service, Food processing.

Cooking VAT Chaudix

- The Chaudix system is an integrated water immersion cooking unit solution with a pneumatic unloading system for the cooking basket. It can be equipped with the Balix system for loading products with European 200 L trolley.

- Ergonomically designed

- Food safety

- Insulated tank with steam proof lid

- Water temperature and level regulation

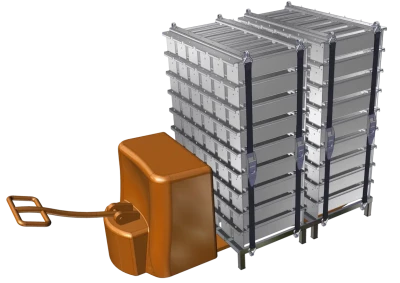

Kit Multimolds

The patented Multimolds kits are design to shape meat products for customers using other cooking and chilling technologies than the Thermix system. The Multimolds kits are used in different applications in the food processing industry.

Kit Multimolds

- The patented Multimolds kits are a 100% stainless steel custom design molds that guarantees total flexibility in products shapes.

- Optimum product shape consistency with accurate dimensions thanks to constant positive interlocks

- Uniform cooking thanks to specifically designed channels for the circulation of the heat transfer fluids

- Optimum hygienic conditions thanks to its sanitary design

- Custom made Multimolds to suit each customer’s need

Kitchenix

The Kitchenix is a fully automated advanced water cook & chill system for Sous Vide cooking technology. It has been specially designed to meet small and medium production needs like Restaurants, Ghost and satellite kitchens and Caterers.

Kitchenix

- The Kitchenix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Kitchenix to suit customer's need

- The Kitchenix system includes Thermix Connect web based controls and mobile app which allow users to monitor overnight cooking without having physical presence on the kitchen.

Thermix Sous Vide

Thermix Sous Vide System is a fully automated, advanced water cook & chill process especially design for Sous Vide cooking technology. Industrial food processors can consistently produce guaranteed safe food product of the best quality at highest yields. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope.

Thermix Sous Vide

- Thermix system flexible, unique design and controls allows processing a variety of products simultaneously. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

- Best consistency & clean label

- Undisputed quality

- Food safety & traceability

- Optimum product flexibility

- Energy saving & minimizing waste

- Minimized processing and labor costs

- Custom made Thermix to suit customer's need

- The automated Thermix Sous Vide System works continuously at a steady pace of 0.5 to 5 tons per hour with various levels of automation delivering a constant flow of superior-quality products with minimal human labor involvement. The system streamlined design results in exceptionally low maintenance costs

Pico Thermix

The Pico-Thermix is by far the smallest unit that we developed with our industrial customers to perform R&D tests with the same level of expertise that the Thermix solution provides. Sous Vide food products are fully vacuum sealed and protected in a high barrier protective envelope. Sous Vide offers the longest shelf life for natural and tasty products without preservatives, resulting in benefits for all users. The Pico-Thermix system flexible, unique design and controls allows processing a variety of products. Immersive water cooking and chilling with continuous circulation, offers the most energy efficient and consistent thermal transfer for optimum product repeatability. Uniformly cooked product at the right temperature delivers the highest yields and undisputed taste profile.

Pico Thermix

- Undisputed quality

- Food safety & traceability

- Integrated heating & chilling

- Best consistency & clean label

- Batches of 4-6kg | 11lbs

- Advanced recipe controls

- Complete traceability plotting

- Remote web-based monitoring Thermix™ Connect

- Suited for 220/50Hz and 220V/60Hz

- No plant utility required. Works perfect at home.

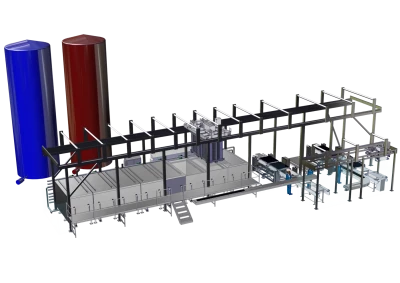

Camatix Pasteurization

The Camatix is fully continuous Sous Vide in-package pasteurization or cooking system that allows processors to produce best quality meals for consumers who demand clean label products. In package thermal pasteurization has become the most reliable and cost effective method for guaranteeing safe RTE products with little or no antimicrobial ingredients to stabilize pathogenic bacteria.

Camatix Pasteurization

- A continuous carousel product handling system with automated, multi-level loading and unloading cages, ensuring high capacity throughput into a reduced footprint.

- Different successive agitated water processing tanks for: cooking/pasteurizing, and chilling are custom configured for the packaged products.

- Synchronized with multiple packing machines, the Camatix system works continuously at a steady pace of 2 to 5 tons per hour. Its pass through design delivers a constant flow of superior-quality products.

- The products are organized in the outfeed of the Camatix replicating the position they had in the infeed.

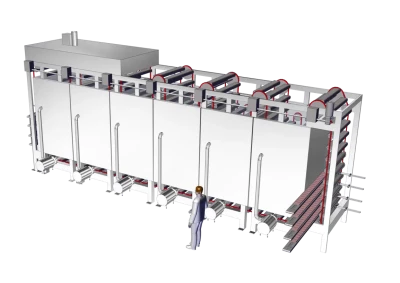

Industrial Rooms for CMP

CMP is short for Continuous Maturing Process and represents our continuous maturation system. With this technology, we distinguish ourselves from all other systems through shorter processing times, product uniformity combined with increased product capacity. This unique system is able to perform the maturing and drying process without any breaks. Due to the control of relative humidity and temperature for inlet and outlet air, it is possible to dry products without any variation. The system is able to move the air continuously (100% of the time) without any rest period.

Industrial Rooms for CMP

- Complete consistency means less than 1% deviation in the entire processing room

- Saving up to 30% processing time

- Significant energy savings

- Optimal utilisation of footprint and room height with full trolley loading up to 6 m in height

- Up to 250% more product can be produced in the same footprint than with comparable systems.