- Home

- Slicing Loading and Packaging

- Packaging Equipment

Packaging Equipment

Food packaging is defined as enclosing food to protect it from tampering or contamination from physical, chemical, and biological sources, with active packaging being the most common packaging system used for preserving food products.

CORR VAC Mark III

Modified Atmosphere Packaging, also known as M.A.P. packaging equipment. Preserves, protects and extends the shelf life of your products. Whether it is individual bags, lined cases, bulk-bin, totes, Gaylords, barrel, or super-sacks, RGMTSI has a proven solution.

CORR VAC Mark III

- 100% stainless steel and FSMA, FDA, & USDA compliant. Optional 3A dairy-grade

- Always ready for wash-down as we build-to IP69 specifications assuring IP67 compliance

- Seal bars available include either 30, 54, 62, and 100-inch lengths

- Vacuum pump standard or optional liquid-ring and venturi

- Hot-bar or impulse sealing

- Bag-stretcher option to insure wrinkle free bags

- Optional two hand controls

- Flexible probes reduces damage and extends life

- A variety of language options on our simple to understand controller

- Floor mount, optional casters, or unit can hang over conveyor.

- Gas flush any product that degrades in atmosphere

- Multi-gas flush totes or super-sacks of organic products assuring inserts and larvae are asphyxiated.

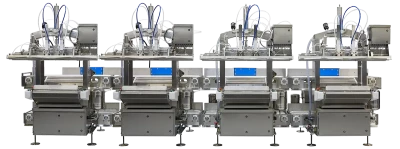

Mark III mHSP MAP Machine

Presenting the 3rd generation multi-station incorporating all of the features our customers have requested over the years while providing the safest, most sanitary and well thought out M.A.P. packaging machine of its kind on the market. Available in 2, 3, 4 or more stations allowing for unprecedented flexibility and now with higher Modified Atmosphere Packaging speeds. Each module includes its own infeed as well as outfeed belt. Start with 2 or three stations and easily add a 4th module in minutes as they interface and communicate by simply connecting a water-tight cable.

Mark III mHSP MAP Machine

- You thought there was a placeholder text here, but it was me DIO!

A200 Bin Modified Atmosphere Packaging Machine

The A-200 Bin Machine line brings the advantages of Modified Atmosphere Packaging to large and bulk items. Full pallets and bins can now be processed efficiently. Wrinkle free seals are achieved with seal bars up to 100 inches (2540mm) and automatic bag stretchers or clamps. Floating head prevents bag pullout.

A200 Bin Modified Atmosphere Packaging Machine

- You thought there was a placeholder text here, but it was me DIO!

CORR VAC MAP VAC

This Modified Atmosphere Packaging Machine has a 1355 mm (53.5-inch) seal-bar, polished, engineered not to bend or distort providing unprecedented and repeatable seal pressure. Wrinkles and gussets are no longer an issue, the MAP-Vac simply seals through them. Twin Teflon gas-flush / vacuum probes at 9.25” or 15 inch spacing opens easily and can be 100% sanitized

CORR VAC MAP VAC

- Twice the seal. Introducing a first of its kind Dual-Pinch, Dual-Seal, hot bar sealing system with cooledge technology. No other M.A.P. machine offers such a wide seal surface area.

- The Corr-Vac MAP-Vac has retractable bag stretchers for quick access for ease of use.

- The B & R model C30 TFT full-color 7” power-panel touch screen offers 4/8 program capability.

- By pressing both cycle buttons simultaneously, the operator's hands are out of the way of the closing seal bar

CS Bag Loader

Bag Loader can semi-automatically load exact counts of sausages into bags. This unit can bag skinless or skin-on, cooked and chilled frankfurters from 12 to 32mm diameters* and from 3” length (7mm) to 12” length (300mm).

CS Bag Loader

- The bag loader can load up to 1,500 pieces per minute of a 5” long (127mm) product with a 98% fill rate, using 3, 4, 6 or 8 manual bagging stations.

- All frankfurter loaders feature touch screen controls that allow for the easy addition of new recipes and rapid adjustment to various areas of the loader.

- All loaders offer a unique first-in/first-out handling method minimizing recirculation of product.

- This unit’s intermediate conveyor inspection flights are made of rugged stainless steel, as is most of the machine, making this the toughest loader on the market.

CS Canning System

CS-Canning System is designed for loading speeds up to 400 cans per minute at seven sausages per can. The system allows manufacturer to electronically program multiple sausage counts per can. Long sausages are fed into the optional Slicer (below right), which cuts them into equal length pieces. The cut pieces are dropped onto a conveyor, go through a metal detector, and then feed into a collator to gain product alignment. The product drops from the collator onto a grouping conveyor and then into the canner.

CS Canning System

- You thought there was a placeholder text here, but it was me DIO!