- Home

- Industries

- Slaughter Line

- Beef

Beef Equipment

Beef is the culinary name for meat from cattle. In prehistoric times, humans hunted aurochs and later domesticated them. Since then, numerous breeds of cattle have been bred specifically for the quality or quantity of their meat. Today, beef is the third most widely consumed meat in the world, after pork and poultry. RGMTSI provides and maintains high-quality slaughter solutions along with cutting and deboning lines for cattle and veal. Our solutions are efficient, robust, ergonomic, hygienic, food safe and innovative.

Robotic Hock Cutter

JR-50 Robotic Beef Hock Cutter for automatic hock cutting operations on the kill floor.

Robotic Hock Cutter

- Six-axis Robotic Beef Hock Cutter – capable of line speeds of up to 450 carcasses per hour.

- Real-time vision for precise and consistent cuts.

- User adjustable parameters to optimize yields.

- Remote diagnostics capability.

- Stainless steel base and a completely jacketed arm makes the JR-50 easy to clean and maintain.

- Stainless steel protective fencing.

- Small footprint to conserve space on the slaughter line.

- Industrial hardened, real-time controller with 3-D vision.

Non Penetrating Pneumatic Stunner

USSS-2 & 2A- pneumatically operated high speed, non- penetrating stunner for cattle and veal.

Non Penetrating Pneumatic Stunner

- Unique design renders the stunned animal insensible to pain, without penetrating the skull.

- One shot humane stunning procedure. Fires only once – no multiple firing needed.

- Better stunning for improved meat quality.

- Two hand control for safer operation.

- Easy to handle and safe to operate – no recoil or kick back – less operator fatigue.

- Easy to repair and clean.

- Lightweight – tool only weighs 36 pounds(16.3 kg).

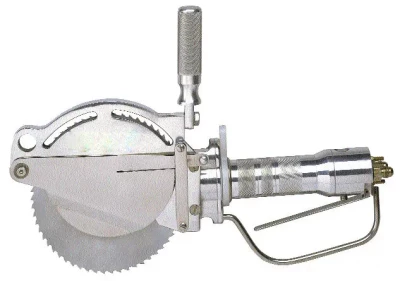

Hydraulic Circular Saw

SHC 140 and SHC 165 hydraulic powered general purpose breaking saws.

Hydraulic Circular Saw

- The right or left handed SHC140, with a 1.5 in (38 mm) cutting depth, or SHC 165 with a 2 in (51 mm) cutting depth are ideally suited for:

- Beef: Breaking forequarter and beef plates, also hot and cold ribbing.

- Pork: Ham and shoulder marking, ribbing and chine bone removal

- Lightweight with hydraulic power – no bogging down, no motor icing, low noise, and instant stop.

- Heavy duty gears made to withstand all uses in the packing plant industry.

- Rugged, corrosion resistant construction for optimum hygiene.

- New style USDA approved blade guard for easy internal sanitation.

- Lever style adjustable depth gauge for precise depth control cutting.

- Instant blade stop.

- Meets national and international requirements for hygiene and safety.

Head Dropper

3HD hydraulically powered hog or beef head dropper.

Head Dropper

- The 3HD quickly and easily severs the head from butcher hogs, sows, boars and beef.

- Fast – a single operator can handle up to 1200 hogs / hour.

- Designed for optimum handling and maneuverability.

- Robust stainless steel construction, including solid stainless steel blades and single piece clevis for best possible hygiene and low maintenance.

- Greasable pivot points for extended life.

- Anti-tie down controls for operator safety.

- Meets national and international requirements for safety and hygiene.

Dehorner

50G hydraulic powered guillotine style dehorner.

Dehorner

- Cuts both horns of all beef closer to the skull than possible with traditional shear type dehorners.

- 1.5 second cycle for high speed production.

- Optional clamshell blades yield an even deeper cut, completely under the horn.

- Best possible hygiene with updated, virtually all stainless steel construction – minimal corrosion problems.

- Robust construction for long trouble-free life.

- Anti-tie down controls for operator safety.

- Meets national and international requirements for safety and hygiene.

JC IV Dehider

JC IV pneumatically powered dehider.

JC IV Dehider

- RGMTSI service technicians are available to provide FREE customer service, including equipment installation, service calls, and employee training.

- Constant torque air motor. Speed doesn’t fluctuate due to air pressure change.

- Dynamic balance drive mechanism for low vibration and wear reduction.

- Extra-thin head with stainless steel center plate for exceptional handling and enduring strength.

- Highest possible hide quality – skins perfectly; no cuts, marks or holes.

- Lightweight – only 3.1 lbs (1.4 kg).

Chitterlings Cutter

HCC-1 hydraulically powered chitterlings cutter.

Chitterlings Cutter

- The HCC-1 is specifically suited to cut the intestines of beef, hogs and sheep.

- Flexible – cuts the intestine any desired length.

- Accurate – mechanically controls the length of cut.

- Quick and easy blade change.

- Constructed from all stainless steel for easy cleaning and optimum hygiene.

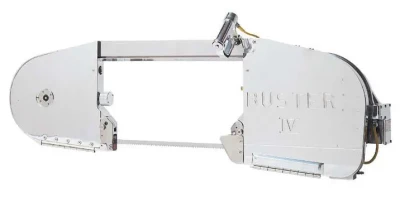

Buster IV Carcass Splitting Bandsaw

Buster IV electrically powered bandsaw for splitting cattle, pigs and sows.

Buster IV Carcass Splitting Bandsaw

- Used in all major U.S. plants for splitting fat cattle (800 – 1050 lbs / 360 – 480 kg).

- Smaller and better handling for optimum performance in the most demanding applications (up to 180 beef / hour / saw).

- Superior blade life: 400 – 600 carcasses per blade.

- Best possible hygiene – spoked wheels, flat surfaced housings and completely opening doors – for fast, easy and complete cleaning.

- The drive system is oil bath lubricated for sustained trouble-free operation.

- Designed for the operator – ultra-thin rail for unobstructed vision and dual rear handles for comfort.

- Anti-tie down controls and totally enclosed electric motor for operator safety.

- Meets national and international requirements for hygiene and safety.

Breaking Circular Saw

1000-FS – hydraulically powered breaking saw.

Breaking Circular Saw

- The 1000-FS, with a 3 to 6.0 in (76 to 152mm) depth of cut, is ideally suited for:

- Beef: chucks, shoulders, ribs, forequarters, chine bones, briskets, loins and aitch bones.

- Pork: chine bones and ham marking.

- High powered hydraulic motor – no bogging down, no motor icing, low noise and instant stop.

- Anti-tie down controls for operator safety.

- Constructed from corrosion resistant materials for optimum hygiene.

- Meets national and international requirements for safety and hygiene.

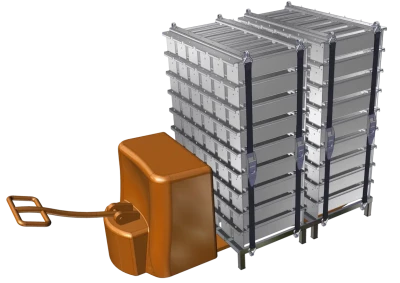

Kit Multimolds

The patented Multimolds kits are design to shape meat products for customers using other cooking and chilling technologies than the Thermix system. The Multimolds kits are used in different applications in the food processing industry.

Kit Multimolds

- The patented Multimolds kits are a 100% stainless steel custom design molds that guarantees total flexibility in products shapes.

- Optimum product shape consistency with accurate dimensions thanks to constant positive interlocks

- Uniform cooking thanks to specifically designed channels for the circulation of the heat transfer fluids

- Optimum hygienic conditions thanks to its sanitary design

- Custom made Multimolds to suit each customer’s need