- Home

- Industries

- Slaughter Line

- Beef

Beef Equipment

Beef is the culinary name for meat from cattle. In prehistoric times, humans hunted aurochs and later domesticated them. Since then, numerous breeds of cattle have been bred specifically for the quality or quantity of their meat. Today, beef is the third most widely consumed meat in the world, after pork and poultry. RGMTSI provides and maintains high-quality slaughter solutions along with cutting and deboning lines for cattle and veal. Our solutions are efficient, robust, ergonomic, hygienic, food safe and innovative.

Meat Tenderizer

Meat Tenderizer is one of the most important components in the production of boneless cooked products such as ham, shoulder, chicken or other meats. A conveyor feeds product to a set of rollers equipped with circular knives. This effectively increases the meat surface and opens the muscle tissue, boosting liquid retention and promoting higher concentration of protein at the surface after massaging. The rollers are designed for easy sanitation and do not need to be disassembled to clean the knives.

Meat Tenderizer

- Used for boneless cuts of pork, beef, chicken, or turkey

- Increases the absorption capacity of meat by opening muscle fibers and exposing inner meat surfaces.

- Increases the quantity of muscle protein on meat surfaces for further processing.

- Rollers equipped with circular knives.

- Accommodates product up to 3-1/8" (80 mm) thick.

- Open design of knife roller for easy sanitation.

- Optional hopper for loading product onto conveyor.

Dehider Blade Reconditioner

BR-5 / BR-5A / BR-5B and BR-5D for perfect dehider blade sharpening.

Dehider Blade Reconditioner

- The Model BR-5 / BR-5A / BR-5B / BR-5D for perfect dehider blade sharpening.

- Sharpens 100mm (BR-5), 110mm (BR-5A), 90mm (BR-5B), or 100mm and 110mm (BR-5D) according to original design specifications – reduces material removal for longer blade life.

- Automatic positioning for dubbing – no fine adjustment required, simply select a fine, medium, or heavy dub.

- Precision indexer centres each tooth perfectly, eliminating operator errors – minimal training required.

- Perfect blades every time, nothing else required.

Dehider

JC IIIA pneumatically powered dehider.

Dehider

- The number one skinning tool worldwide for cattle, veal, hogs and sheep.

- Highest possible hide quality – skins perfectly; no cuts, marks or holes.

- High capacity, high performance tool, designed for long life and low maintenance.

- Super efficient motor design – only 12 ft 3 / min at 45 psi (0.34 m3 / min at 3.1 bar).

- Extra-thin head with stainless steel center plate for exceptional handling and enduring strength.

- Lightweight – only 2.9 lbs (1.3 kg).

Carcass Splitting Saw

Buster V electrically powered bandsaw for splitting bulls, cows and horses.

Carcass Splitting Saw

- Used worldwide for splitting fat cattle, bulls, oxen, and horses.

- The largest Jarvis splitting saw; suited for the largest animals.

- Superior blade life: 400-600 carcasses per blade.

- Best possible hygiene – spoked wheels, flat surfaced housings, and completely opening doors – for fast, easy and complete cleaning.

- The drive system is oil bath lubricated for sustained trouble-free operation.

- Designed for the operator – ultra-thin rail for unobstructed vision and dual rear handles for comfort.

- Anti-tie down controls and totally enclosed electric motor for operator safety.

- Meets national and international requirements for hygiene and safety.

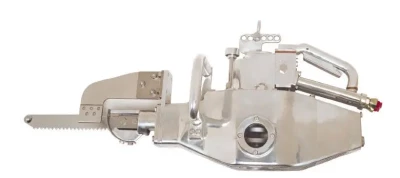

Brisket Saw

Hydraulic powered brisket saws for beef, hog splitting and forequartering.

Brisket Saw

- The powerful MG-1 cuts through all beef briskets quickly and easily. The high performance MG-1B is even faster, suitable for kills over 200 beef / hour. Models MG-1HS and MG-1BHS are ideal for hog splitting and hog brisket cutting. Model MG-1BFQ is the perfect saw for forequartering.

- The MG-1 and MG-1HS cuts fat cattle briskets in 5 seconds, the MG-1B, MG-1BHS and MG-1BFQS in 3 seconds.

- Small and maneuverable for optimum handling.

- A balanced drive system makes all MG-1 models smooth and quiet for less operator fatigue.

- Minimal maintenance due to the oil bath lubricated drive and no electrical components.

- Meets international requirements for safety and hygiene. USDA and CE approved.

Beef Hock Cutter

30CL-1 hydraulically powered fore and hind beef hock and horn cutters.

Beef Hock Cutter

- Used for front and hind beef hock cutting through the bone or joint. Also an effective beef dehorner.

- With a 1.5 second cutting cycle, it is a high production, high performance tool -used extensively for the most demanding applications.

- Anti-tie down controls and dual control triggers for operator safety.

- Please note the pinch point, thumb and trigger guards on both tools, as shown in the above photos.

- Meets national and international requirements for safety and hygiene.

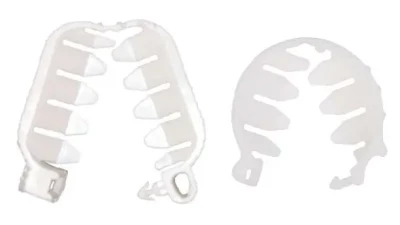

Weasand Clips

for sealing the esophagus of slaughtered stock.

Weasand Clips

- Weasand clips are designed for sealing the esophagus of slaughtered beef and sheep.

- Made of plastic in the U.S.A.

- Designed to keep the esophagus sealed tightly during processing procedures.

- Shipped in clear plastic bags for optimum hygiene and convenience.

- Beef: Available in white, blue and black

- Also available: Rodder for beef and Rodder for sheep

Straight Blade Reconditioner

SBR-2 for perfect straight blade sharpening.

Straight Blade Reconditioner

- Ideal for sharpening blades for brisket, quartering and carcass splitting saws.

- Sharpens any size reciprocating blade up to 2.5 inches in width.

- Sharpens blades to original design specifications – reduces material removal for longer blade life.

- Precision ground teeth reduce operator fatigue, also wear and tear on equipment.

- Accurately regrinds badly damaged blades – grinds chipped or broken teeth like new.

- The SBR-2 produces perfect blades every time – nothing else is required.

Steam Vacuum Hock Cleaning System

HS-1 and HS-2 steam vacuum hock cleaning systems.

Steam Vacuum Hock Cleaning System

- The HS-1 and HS-2 are specifically designed for microbial reduction and the removal of contaminants from the front legs (HS-1) and rear hocks (HS-2).

- Increases shelf-life by reducing the amount of bacteria found on the carcass.

- Increases yields – less trimming required.

- Lightweight handpiece for optimum operator comfort.

- All stainless construction for maximum hygiene.

- Vacuum systems sized specifically for your requirements.

Spinal Cord Removal System

SR-1 vacuum system for spinal cord removal on beef or hogs.

Spinal Cord Removal System

- Increases shelf life.

- Fast – one operator can handle 800 hog or 350 beef carcasses per hour.

- Lightweight handpiece for optimum operator comfort.

- High vacuum ensures that operator traces spinal cavity only once to remove the cord.

- All stainless steel construction for maximum hygiene.

- Hardened nozzle tip for better scraping action.