- Home

- Thermal Processing

- Chill

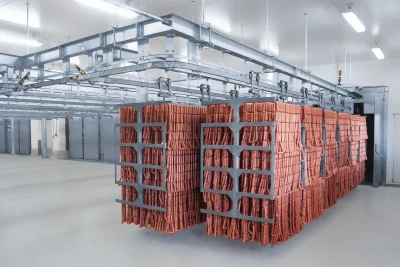

- Semi continuous batch system KCS

Semi continuous batch system KCS

The production process takes place continuously in a continuous batch system; from filling to packaging, there is no delay in the processing of products.

Features

- “Inline” production: The production process is performed inline with the semicontinuous loading system, i. e. there is no processing delay between filling and packaging.

- 100% Separation between low and high risk areas: The airtight transfer zone between the entry and exit sides allows the separation of production and packaging areas (“low-risk“, “high-risk“).

- Integration: The system can be integrated into the production area due to upstream and downstream automation.

Possible Application(s)

Semi continuous batch system KCS is best suited for: